Urea Formaldehyde CAS 9011-05-6

Factory wholesale Urea Formaldehyde CAS 9011-05-6

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Urea Formaldehyde

CAS: 9011-05-6

MOQ: 1KG

Directory Guidance on Urea Formaldehyde

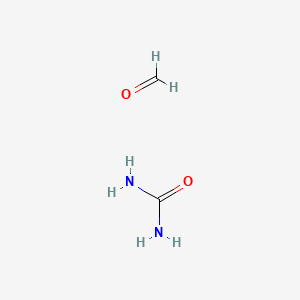

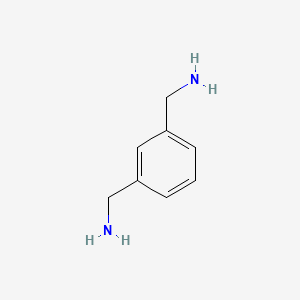

Chemical Structure

Basic Info:

| density | 1.200 g/cm3 |

| storage temp. | -20°C |

| Dielectric constant | 6.4(Ambient) |

Product Introduction:

Urea Formaldehyde, also known as urea formaldehyde resin, abbreviated as UF, is a synthetic resin with an average molecular weight of about 10,000. In industrial production, alkali is usually used as a catalyst, and the reaction is carried out at about 95°C, and the molar ratio of formaldehyde to urea is generally controlled between 1.5 and 2.0. Such a ratio can ensure that the resin has good curing properties. The first step of the reaction will generate mono- and dimethylol urea, and then the methylol and amino groups will further condense to obtain a soluble resin. If acid catalysis is used, it is easy to cause the formation of gel, so the product needs to be stored under neutral conditions. Linear Urea Formaldehyde can be cured at room temperature when ammonium chloride is used as a curing agent, while molding powder needs to be cured under heating conditions of 130-160°C. Adding accelerators such as zinc sulfate, trimethyl phosphate, and diethyl oxalate can effectively accelerate the curing process.

From the perspective of physical properties, Urea Formaldehyde is generally a colorless or light yellow crystal or granular solid with good heat resistance, chemical corrosion resistance and mechanical strength. It also has good bonding properties to other materials, and can control the curing speed and hardness by adjusting the proportion of urea and formaldehyde according to actual needs. This resin was first successfully developed by the British Cyanamide Company in 1924 and began to be marketed in 1928. By the mid-1930s, its output had reached the thousand-ton level. By the 1980s, the world’s annual output exceeded 1.5 million tons. It is one of the earliest developed and widely used thermosetting resins.

In terms of production technology, the raw materials for manufacturing Urea Formaldehyde are mainly urea and formaldehyde, which undergo polycondensation under specific reaction conditions. During the reaction, environmentally friendly formaldehyde and ordinary formaldehyde are first mixed in a certain proportion and added to the reactor, and the agitator is started, followed by the addition of additives such as polyvinyl alcohol, and then urea is added to start heating. After the heat preservation reaction is completed, ammonium chloride is used to adjust the pH value. After gelation, the temperature is lowered to about 45°C, stirring is stopped, and the discharge is completed. The process is relatively simple to make, easy to operate and easy to master, which is also an important reason why Urea Formaldehyde can be mass-produced and widely used.

Nature and Specifications:

| Item | Specification |

| Product Name | Urea Formaldehyde |

| CAS No. | 9011-05-6 |

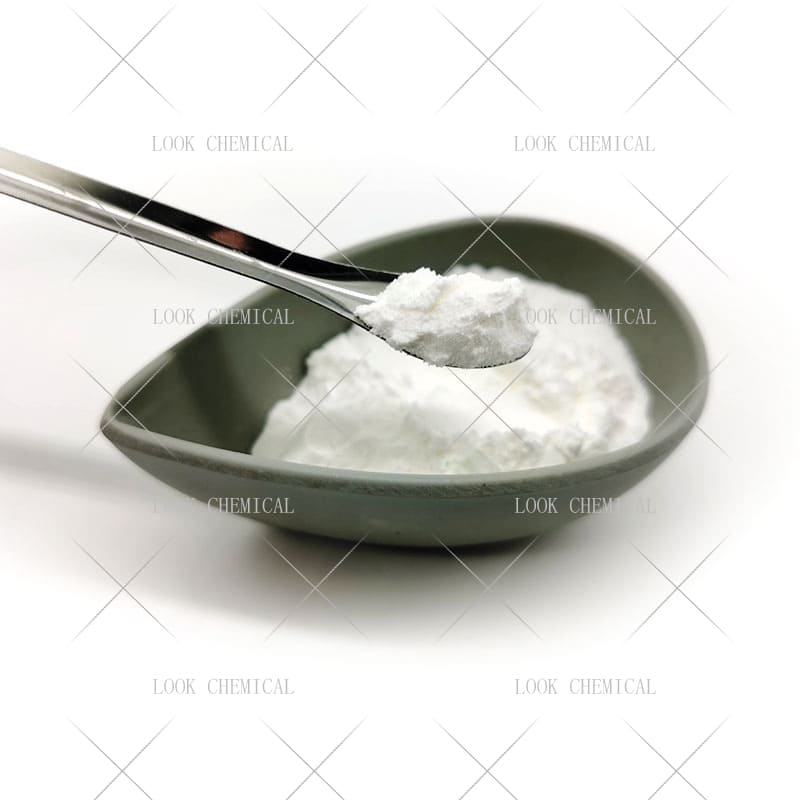

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| CAS: | 9011-05-6 |

| MF: | C2H6N2O2 |

| MW: | 90.08 |

| EINECS: | 618-464-3 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

As an important branch of synthetic resin, the application of Urea Formaldehyde has broken through the boundaries of traditional wood processing industry and extended to high-end fields such as construction, transportation, and electronics. In the field of wood processing, its core value is reflected in the production of plywood, particleboard, and medium-density fiberboard.

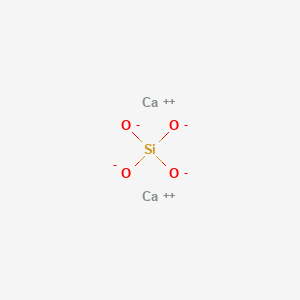

The construction industry has made more diversified use of Urea Formaldehyde. In addition to traditional artificial boards, its modified products can be used as core components of waterproof coatings and sound insulation materials. For example, urea-formaldehyde foam with added flame retardants is used in building interlayers, which can not only achieve thermal insulation, but also meet fire safety standards. In the field of decoration, artificial stone made of resin and inorganic fillers has both natural texture and high surface hardness, becoming a new decoration solution for countertops and walls. It is worth noting that with the popularization of the concept of green building, the acceptance of modified urea-formaldehyde products with low formaldehyde emission in interior decoration has gradually recovered.

The application of the automotive industry highlights the comprehensive performance advantages of the material. In the manufacture of vehicle interiors, Urea Formaldehyde is used for bonding and fixing of structural parts such as dashboards and door panels, and is also used as a surface coating to improve the scratch resistance and glossiness of parts. Its fast curing characteristics meet the rhythm requirements of automobile production lines, while the impact resistance obtained by blending modification ensures the reliability of parts in vibration environments. In addition, in emerging fields such as new energy vehicle battery pack packaging, its insulation and chemical corrosion resistance have also received attention.

The needs of the electronic and electrical industry are driving the functional upgrading of materials. Electrical plastic products such as socket shells and switch panels are injection molded with Urea Formaldehyde, which not only meets the rigid standards of flame retardancy and arc resistance, but also can realize complex structure manufacturing through precision molds.

Innovative applications in the textile field are also worthy of attention. As a fabric finishing agent, Urea Formaldehyde can give cotton and linen products a lasting anti-wrinkle effect, and fix the fabric shape through the hydrogen bonding between the molecular chain and the fiber. In the processing of special textiles, its synergistic use with flame retardants and antibacterial agents creates multifunctional composite fabrics, which are widely used in medical protection and industrial protection. This cross-field application migration reflects the designability and process compatibility of material formulations.

The special needs of the energy industry have given rise to a differentiated product system. In oilfield water plugging technology, Urea Formaldehyde solution is used as an intelligent plugging agent to achieve selective filling of formation pores by regulating the curing time and particle size

Urea Formaldehyde has high hardness, which can meet many application scenarios that require hardness, such as manufacturing plastic products such as tableware, beverage bottle caps, kitchen utensils, and for making high-hardness coatings and paints, etc., providing reliable guarantees for the performance of the product.

At the same time, its oil-resistant and mildew-resistant properties enable it to maintain good performance in some special environments, and it is not easily corroded by oil substances and invaded by mold, which prolongs the service life of the product.

Urea Formaldehyde has good light resistance, is not prone to discoloration during long-term use, and can maintain color stability even during thermoforming, which gives it a unique advantage in the manufacture of products that need to maintain a beautiful appearance, such as the production of colorful and beautiful daily plastic products, electrical lighting equipment housings, etc.,

In addition, Urea Formaldehyde contains polar oxygen atoms in its molecular structure, which gives it good adhesion to the surface of the object, so that it can better combine with the surface of the adherend in the field of coatings and adhesives, improve the adhesion of the coating and the bonding strength of the adhesive, whether used for primers, intermediate layer coatings or as adhesives, it can effectively enhance the performance of the entire coating system or bonding system, and ensure the quality and durability of the product.

Contact Us

Product Package picture:

Related References:

chemicalbook-Urea Formaldehyde

Urea Formaldehyde Manufacturer

Contact Us

As an experienced Urea Formaldehyde manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Urea Formaldehyde CAS 9011-05-6 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.