Trixylyl Phosphate CAS 25155-23-1

Factory wholesale Trixylyl Phosphate CAS 25155-23-1

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Trixylyl Phosphate

CAS: 25155-23-1

MOQ: 1KG

Directory Guidance on Trixylyl Phosphate

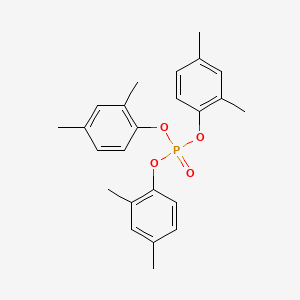

Chemical Structure

Basic Info:

| Melting point | -19.9°C |

| Boiling point | ≥300 °C(lit.) |

| density | 1.136 g/mL at 20 °C(lit.) |

| vapor pressure | 0Pa at 20℃ |

| refractive index | n20/D 1.552 |

Product Introduction:

Trixylyl Phosphate, referred to as TDP, is an important organophosphorus compound. Its molecular formula is C24H27O4P, and its relative molecular mass is 410.44. At room temperature and pressure, Trixylyl Phosphate usually appears as a colorless or light yellow viscous liquid with a slight special smell. Its physical properties are relatively stable and not easy to volatilize. Its density is about 1.130~1.160g/cm³ (20℃), its refractive index is about 1.551~1.555 (25℃), and its flash point is relatively high, generally greater than 230℃, which makes it relatively safe during storage and use, and not prone to dangerous situations such as combustion or explosion.

From the chemical structure point of view, Trixylyl Phosphate is composed of three xylene groups and a phosphate group connected by an ester bond. This special molecular structure gives it many excellent properties. First, the xylene group in its molecule has a large volume and strong hydrophobicity, which makes the whole molecule very soluble in organic solvents, but relatively weak in water. The characteristic of being slightly soluble in water gives it a unique advantage in some materials that need to be waterproof or used in humid environments. Secondly, the presence of the phosphate group not only provides good polarity, which helps to improve its compatibility with polar materials, but also gives it certain flame retardant properties, because phosphorus can promote the formation of a stable carbonized layer on the surface of the material at high temperatures, thereby playing a role in heat insulation and oxygen isolation, delaying the spread of fire.

There are two main methods for the synthesis of Trixylyl Phosphate. One is to esterify xylenol with phosphorus trichloride, and then obtain it through a series of post-treatment steps such as hydrolysis and neutralization; the other is to directly esterify phosphorus oxychloride with xylenol under the action of a catalyst. These two methods have their own advantages and disadvantages. The former has relatively mild reaction conditions, but has more reaction steps and higher requirements for equipment and operation; the latter has higher reaction efficiency, but requires more stringent control of reaction conditions, such as temperature, pressure and catalyst dosage. At present, most industries use improved synthesis processes to improve product quality and yield while reducing production costs and environmental pollution.

Nature and Specifications:

| Item | Specification |

| Product Name | Trixylyl Phosphate |

| CAS No. | 25155-23-1 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 232℃ |

| storage temp. | Hygroscopic, Refrigerator, under inert atmosphere |

| solubility | Acetonitrile (Slightly), Chloroform (Slightly) |

| form | liquid |

| color | Colourless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Trixylyl Phosphate has become an increasingly important ingredient in plastic processing, serving primarily as an additive for materials like PVC and polyurethane. Plasticizers can help to enhance low-temperature brittleness of hard plastics and decrease their glass transition temperatures by 20-30 degrees while simultaneously maintaining mechanical strength at room temperatures. Comparative to phthalate plasticizers, its molecular structure features stronger polarity. Furthermore, its compatibility index with PVC resin surpasses 0.92; this prevents surface frost or exudation from happening with long-term usage of the product. Trixylyl Phosphate-modified PVC leather excels at meeting automotive interior manufacturing specifications.

Trixylyl Phosphate’s use in polar rubber systems such as nitrile rubber and chloroprene rubber has become increasingly prominent in the rubber industry. As a multifunctional processing aid, it not only reduces Mooney viscosity of compound rubber compounds and increases filler dispersion uniformity but can also play an integral part in flame retardant vulcanization processes.Notably, its oil extraction resistance is incredible: after immersion for 72 hours in ASTM No.3 standard oil for 72 hours its mass loss rate was less than 3% – much lower than traditional plasticizers like DOP!

Trixylyl Phosphate demand in the coating and adhesive industries has experienced an explosive increase in recent years, marking a clear growth trend. Epoxy resin systems often utilize it as a reactive flame retardant, and its molecules’ hydroxyl groups undergo grafting reactions with epoxy groups for chemical bonding to form stable chemical bond structures. This modification method not only increases the flame retardant rating (UL94 V-0), but also dramatically enhances chemical corrosion resistance of the coating. Trixylyl Phosphate’s low surface tension characteristics (about 32mN/m) allow it to effectively decrease particle size distribution across an emulsion, and reduce particle size distribution span. The prepared leather finishing agent boasts dynamic folding resistance of more than 100,000 times while maintaining flame retardancy, with unique light stabilization properties in a UV curing system, which inhibits premature crosslinking of acrylate monomers and decreases coating defect rate by over 40%.

Trixylyl Phosphate’s synergistic effect in engineering plastic alloys is of immense benefit from a material modification perspective. When combined with nitrogen-based flame retardants and applied to PA6, its combined effect increases LOI from 21% to 34%, maintaining over 12g/10min melt flow rate while simultaneously inhibiting droplet phenomenon during combustion as well as increasing impact strength by 15%-20% via interfacial volume expansion.

The core competitiveness of Trixylyl Phosphate is first reflected in its unique multifunctional integrated characteristics. Unlike single-function additives, Trixylyl Phosphate can simultaneously achieve multiple goals such as plasticization, flame retardancy, and lubrication. This integrated advantage significantly reduces the complexity of the material formulation. In the rigid PVC pipe formulation, it can replace the traditional three-component system of plasticizer/flame retardant/processing aid, shortening the mixing process time by more than 25%. The aromatic ring system in its molecular structure forms an electronic conjugation effect with the phosphate group. This electronic distribution characteristic not only gives the material intrinsic flame retardancy, but also enhances the interaction with the polar matrix resin, which is a key advantage that most aliphatic plasticizers cannot achieve.

In terms of high temperature stability, Trixylyl Phosphate performs far better than similar products. Long-term heat aging experiments (150℃×168h) show that its mass loss rate is only 1/3 of DOP, and no harmful components such as benzene series are detected in the volatiles. This property makes Trixylyl Phosphate particularly suitable for medical devices that require repeated high-temperature sterilization. For example, after 100 times of steam sterilization at 121°C, the compression set of silicone rubber seals can still be kept within 15%. From the perspective of processing performance, its viscosity-temperature curve shows an ideal linear relationship, and the viscosity change rate in the range of 80-180°C is less than 20%. This property ensures that it can maintain a stable shear dispersion effect during twin-screw extrusion, which is particularly conducive to the uniform distribution of nanofillers.

Environmental adaptability is another outstanding advantage of Trixylyl Phosphate. Its hydrolysis stability index (HSI) reaches 98 points (out of 100 points), and there is no obvious decomposition after storage in the pH range of 3-11 for 12 months. This wide range tolerance enables it to adapt to water quality conditions in different regions. In the weather resistance test, after 3000 hours of xenon lamp aging, the elongation at break of the Trixylyl Phosphate-modified outdoor cable sheath retained more than 85%, and no powdering phenomenon appeared on the surface. More importantly, the substance complies with the zero content requirements of the EU RoHS 2.0 Directive for six restricted substances, and its REACH registration file is not included in the SVHC candidate list, which provides reliable regulatory compliance guarantees for export-oriented manufacturing companies.

From the perspective of the full life cycle cost analysis, the comprehensive cost performance of Trixylyl Phosphate is significantly competitive. Although its unit price is 15%-20% higher than that of traditional plasticizers, the overall cost is reduced by 10%-15% because the addition amount can be reduced by 30%-40% (flame retardant synergy) and the service life of the product is extended by more than 50%. In the application scenario of automotive wiring harnesses, the thin-walled insulation layer design using Trixylyl Phosphate can reduce the weight of the cable by 18%, while meeting the long-term use temperature requirement of 150°C. This lightweight benefit is of great value to the improvement of the cruising range of new energy vehicles. It is worth noting that the atomic utilization rate of the Trixylyl Phosphate production process reaches 92%, and the only by-product is hydrochloric acid (which can be recycled for other chemical processes). This green synthesis route fully meets the requirements of clean production under the background of carbon neutrality.

Contact Us

Product Package picture:

Related References:

chemicalbook-Trixylyl Phosphate

Trixylyl Phosphate Manufacturer

Contact Us

As an experienced Trixylyl Phosphate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Trixylyl Phosphate CAS 25155-23-1 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.