Trititanium Tetrakis(Phosphate) CAS 15578-51-5

Factory wholesale Trititanium Tetrakis(Phosphate) CAS 15578-51-5

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Trititanium Tetrakis(Phosphate)

CAS: 15578-51-5

MOQ: 1KG

Directory Guidance on Trititanium Tetrakis(Phosphate)

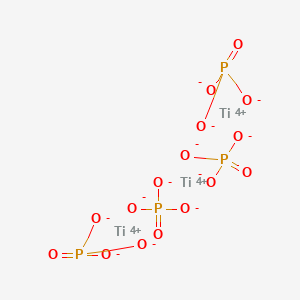

Chemical Structure

Trititanium Tetrakis(Phosphate) Introduction:

Trititanium Tetrakis(Phosphate) is an inorganic compound consisting of titanium, phosphorus and oxygen with unique physical and chemical properties. Depending on synthesis conditions and presence of doping elements, its crystal structure typically falls either into orthorhombic or monoclinic systems; naturally occurring minerals often contain Trititanium Tetrakis; however for industrial uses high purity Trititanium Tetrakis is typically produced via chemical synthesis.

Common preparation methods include hydrothermal method, sol-gel method and high temperature solid phase reaction. Of these approaches, hydrothermal method is generally preferred due to its mild reaction conditions and high product crystallinity; solid-phase method can be utilized for large scale production by controlling parameters like pH, reaction temperature and time in order to produce Trititanium Tetrakis(Phosphate) particles with exact specifications that meet performance needs in different fields.

In terms of physical properties, the thermal stability of Trititanium Tetrakis(Phosphate) is particularly outstanding, with a decomposition temperature usually higher than 800°C, and it can still maintain low dielectric loss at high temperatures, which lays the foundation for its application in the field of high-temperature electronic devices.

Trititanium Tetrakis(Phosphate) exhibits excellent acid and alkali resistance in chemical properties, which makes it have significant advantages in application in corrosive media. At the same time, its abundant hydroxyl groups on the surface give it good ion exchange capacity, which can achieve selective capture of specific metal ions through adsorption or ion replacement.

Trititanium Tetrakis(Phosphate) microstructural characteristics exert a decisive effect on its macroscopic properties, with layers of Trititanium Tetrakis(Phosphate) often serving as the main material of functional composite materials, because other ions or molecules can be added between layers; and nanoscale Trititanium Tetrakis(Phosphate) particles boasting increased catalytic activity due to their large specific surface area and quantum effect.

Nature and Specifications:

| Item | Specification |

| Product Name | Trititanium Tetrakis(Phosphate) |

| CAS No. | 15578-51-5 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| CAS: | 15578-51-5 |

| MF: | H3O4PTi |

| MW: | 145.86 |

| EINECS: | 2396418 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Trititanium Tetrakis(Phosphate)

In the field of the electronics industry, Trititanium Tetrakis(Phosphate) has become a core component of key materials such as high-frequency circuit substrates and microwave dielectric ceramics due to its excellent dielectric properties and thermal stability. Its dielectric constant has a wide adjustable range (usually 10-50), and the tangent value of the dielectric loss Angle is less than 0.001. This characteristic makes it play an irreplaceable role in components such as filters and antenna substrates in 5G communication equipment.

Especially in the application of the millimeter-wave frequency band, the material has extremely high requirements for the stability of dielectric properties. Trititanium Tetrakis(Phosphate) -based ceramics can achieve excellent performance with a temperature coefficient close to zero through composition optimization. Furthermore, Trititanium Tetrakis(Phosphate) thin films have gradually been applied in the passivation layer and gate dielectric layer of semiconductor devices. Their characteristics of high breakdown field strength and low leakage current contribute to improving the reliability of the devices.

The field of energy storage and conversion is another important application direction of Trititanium Tetrakis(Phosphate). In lithium-ion batteries, it can serve as a coating layer for the negative electrode material, effectively inhibiting the decomposition of the electrolyte and the expansion of the electrode volume, thereby extending the battery’s cycle life. Research shows that the silicon-based anode material modified by it can still maintain a capacity retention rate of over 85% after 500 charge and discharge cycles.

In the sodium-ion battery system, Trititanium Tetrakis(Phosphate) itself can serve as the negative electrode active material, and its three-dimensional ion channel structure is conducive to the rapid deintercalation and intercalation of sodium ions. More notably, it has emerged in the research and development of solid-state electrolytes. Its ionic conductivity can reach the order of 10⁻³ S/cm through structural regulation, and its interfacial compatibility with electrode materials is superior to that of traditional sulfide electrolytes.

The applications in the field of catalysis mainly focus on two directions: photocatalysis and acid-base catalysis. The bandgap width of Trititanium Tetrakis(Phosphate) can be adjusted to the range of 2.5-3.2 eV through doping, giving it visible light responsiveness and outstanding performance in photocatalytic hydrogen production and organic pollutant degradation. Compared with traditional TiO ₂ photocatalysts, its carrier recombination rate is reduced by about 40%, and its quantum efficiency is significantly improved.

In terms of acid-base catalysis, its surface acidic sites are evenly distributed and have moderate strength, making it particularly suitable for fine chemical reactions such as esterification and alkylation. The catalyst life is extended by more than three times compared to molecular sieve materials. In addition, the precious metal catalyst supported on Trititanium Tetrakis(Phosphate) also exhibits high selectivity and resistance to carbon deposition in hydrogenation reactions.

In terms of nuclear waste treatment, Trititanium Tetrakis(Phosphate) has a special coordination adsorption capacity for radioactive elements such as uranium and plutonium, and its irradiation stability also meets the strict requirements of the nuclear industry. In addition, the ion screen material based on it can achieve efficient extraction of strategic metals such as lithium and rubidium. The adsorption capacity of lithium extraction from seawater reaches 7 mg/g, which has the prospect of industrial application.

The Advantages Of Trititanium Tetrakis(Phosphate)

Chemical stability is the core competitive advantage of Trititanium Tetrakis(Phosphate). After immersion in an extreme environment of pH = 1-14 for 240 hours, its mass loss rate is less than 0.5%, and the crystal structure has not changed significantly. This characteristic makes its application in the fields of anti-corrosion coatings for chemical equipment and nuclear waste solidification matrix have long-term reliability.

Compared with similar materials such as zirconium phosphate, the corrosion resistance of Trititanium Tetrakis(Phosphate) in concentrated sulfuric acid environment is improved by about 30%, and the preparation cost is reduced by more than 20%. In addition, its antioxidant properties are also excellent. No phase change or decomposition was detected after calcination in an air atmosphere at 600℃ for 100 hours, which provides the possibility for the development of high-temperature filtration materials.

The advantages in thermal performance are reflected in multiple dimensions. The linear expansion coefficient of Trititanium Tetrakis(Phosphate) (4.5×10⁻⁶/℃) is close to that of most metal materials, which enables it to effectively relieve thermal stress in metal-based composite materials and avoid interface cracking problems. In thermal barrier coating applications, its thermal conductivity (1.2 W/m·K) is 40% lower than that of traditional YSZ materials, significantly improving the thermal insulation effect.

More importantly, at a high temperature of 1000℃, the bending strength of Trititanium Tetrakis(Phosphate)-based ceramics still maintains more than 80% of the room temperature value. This high-temperature mechanical stability is of great value in the protection of hot end components of aerospace engines. Thermal shock tests show that after 20 cycles of rapid cooling and heating from 1100℃ to room temperature, no crack propagation occurs on the surface of the material.

From the perspective of industrial production, the synthesis process of 18-Crown-6 has tended to be mature. The multi-step condensation reaction using epichlorohydrin and diols as raw materials can achieve mass production at the kilogram level, and the purification process can be efficiently completed through recrystallization or column chromatography. Compared with some specialty chemicals that require precious metal catalysis or high-pressure conditions, its production cost is more competitive. In addition, its solid form is convenient for storage and transportation, and it can maintain stability for several years at room temperature, significantly reducing the difficulty of supply chain management.

Environmental friendliness is another highlight that distinguishes it from traditional reagents. The biodegradability of 18-Crown-6 is superior to that of most ionic liquids or organic solvents, and it can be oxidized and decomposed into harmless small molecules in conventional sewage treatment. Studies have shown that its median lethal dose (LD50) is higher than 2000 mg/kg (oral administration in rats), which belongs to the low-toxicity category. This provides a safe basis for its application in food packaging or medical devices. Meanwhile, its high conversion rate in catalytic reactions can reduce the discharge of waste liquid, which is in line with the development trend of green chemistry.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Trititanium Tetrakis(Phosphate)

Trititanium Tetrakis(Phosphate) Manufacturer

Contact Us

As an experienced Trititanium Tetrakis(Phosphate) manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Trititanium Tetrakis(Phosphate) CAS 15578-51-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.