Triisobutylaluminum CAS 100-99-2

Factory wholesale Triisobutylaluminum CAS 100-99-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Triisobutylaluminum

CAS: 100-99-2

MOQ: 1KG

Directory Guidance on Triisobutylaluminum

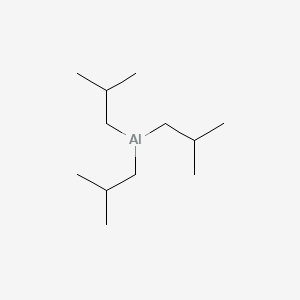

Chemical Structure

Basic Info:

| Melting point | 4-6°C |

| Boiling point | 68-69 °C |

| density | 0.848 g/mL at 25 °C |

| vapor pressure | 75Pa at 25℃ |

| refractive index | 1.4494 |

| Fp | −1 °F |

Product Introduction:

Triisobutylaluminum (TIBA for short, chemical formula Al(O-i-C4H9)3) is an important metal organic compound, which has an irreplaceable position in the fields of industrial catalysis, polymer synthesis and fine chemicals. In its molecular structure, aluminum atoms form a stable coordination structure through three isobutyl groups. This unique spatial configuration gives it excellent chemical reactivity and selectivity. As one of the core components of the Ziegler-Natta catalyst system, Triisobutylaluminum has continued to promote the technological innovation of polyolefin materials since its industrialization in the 1950s. The compound usually exists in the form of a colorless to pale yellow liquid with a density of about 0.78 g/cm³ and a boiling point range of 86-88°C (under 1 mmHg conditions). It is extremely sensitive to air and moisture, and reacts violently with water to produce isobutane and aluminum hydroxide. This characteristic determines that it must be stored and transported under the protection of inert gas.

From the perspective of chemical synthesis, Triisobutylaluminum is mainly prepared by the direct alkylation reaction of aluminum powder and isobutylene under high temperature and high pressure conditions. The process involves the insertion reaction mechanism in metal organic chemistry. During the reaction, aluminum atoms gradually combine with three isobutyl ligands to form a stable three-coordinate structure. Continuous production processes are usually used in industrial production. By precisely controlling the reaction temperature, pressure and raw material ratio, the purity of the product can be increased to more than 99%. It is worth noting that the electron-deficient characteristics of the aluminum element in its molecule give it Lewis acid properties, which can effectively activate a variety of organic substrates. This property plays a key role in subsequent applications.

In terms of physical and chemical properties, Triisobutylaluminum exhibits the characteristics of typical organoaluminum compounds. Its vapor pressure increases exponentially with increasing temperature, and the vapor pressure is about 0.01 mmHg at 25°C. This property directly affects its application design in gas phase reactions. The compound has good thermal stability and no obvious decomposition phenomenon below 150°C, but when the temperature exceeds 200°C, a β-hydrogen elimination reaction will occur to generate isobutylene and aluminum oligomers. This controllable thermal decomposition behavior can be cleverly utilized in certain catalytic systems, such as being used as a chain transfer agent in specific polymerization reactions. In addition, its solubility in different solvents varies significantly. It is easily soluble in hydrocarbon solvents but has reduced stability in polar solvents, which provides an important basis for the selection of solvents in process design.

From the perspective of safety regulations, Triisobutylaluminum belongs to the category of highly dangerous chemicals. Its auto-ignition temperature is about 35°C. When exposed to air, it will immediately cause combustion, producing aluminum oxide smoke and carbon oxides. This potential hazard requires that related operations must strictly follow explosion-proof regulations, including the use of nitrogen inerting systems, anti-static equipment and dedicated conveying pipelines.

Nature and Specifications:

| Item | Specification |

| Product Name | Triisobutylaluminum |

| CAS No. | 100-99-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | 0-6°C |

| form | Solution |

| color | Clear colorless to light yellow |

| Specific Gravity | 0.848 |

| Water Solubility | reacts |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the field of industrial catalysis, Triisobutylaluminum is widely used as an efficient activator in olefin polymerization reaction systems. It significantly improves the catalytic activity and product stereoregularity through synergistic effects with transition metal catalysts (such as titanium and zirconium complexes). In the process of propylene polymerization, the compound can effectively remove poisoning impurities in the system, and at the same time generate active centers through alkyl transfer reactions, which increases the catalyst efficiency by 2-3 orders of magnitude. This characteristic enables the single-line production capacity of modern polypropylene units to exceed 400,000 tons/year, and the product isotacticity can reach more than 99%. In addition, in the metallocene catalyst system, Triisobutylaluminum can be used as a co-catalyst to finely adjust the molecular weight distribution of the polymer to meet the special needs of high-end application scenarios such as automotive parts and medical materials.

The field of fine organic synthesis is another important application direction of this compound. Its strong Lewis acidity makes it the preferred reagent for alkylation and silylation reactions of carbonyl compounds. In asymmetric synthesis, the complex formed by Triisobutylaluminum and chiral ligands can achieve an enantiomeric excess of up to 95%, which is of great value in the synthesis of pharmaceutical intermediates. For example, in the synthesis route of β-lactam antibiotics, Triisobutylaluminum can effectively promote the key cyclization step, shortening the reaction time by about 70% compared with traditional acid catalysts. It is worth noting that its unique selectivity in the introduction reaction of silane protecting groups makes it possible to modularize the skeleton of complex molecules, significantly improving the efficiency of the total synthesis of natural products.

In recent years, the semiconductor manufacturing industry has attached increasing importance to the special application value of Triisobutylaluminum. In the metal organic chemical vapor deposition (MOCVD) process, this compound can be used as an aluminum source precursor to achieve high-quality deposition of aluminum nitride film at a lower temperature (450-550°C). The good matching of its decomposition temperature with the epitaxial growth temperature of gallium nitride reduces the defect density of the prepared semiconductor material to the level of 10^5 cm^-2, meeting the core material requirements of 5G communication devices and ultraviolet LEDs. In addition, in atomic layer deposition (ALD) technology, the alternating pulse reaction of triisobutylaluminum with ozone or water vapor can prepare an ultra-thin aluminum oxide passivation layer with a thickness control accuracy of a single atomic layer, which is crucial to the performance improvement of next-generation memory devices and logic devices.

In the field of new energy material development, triisobutylaluminum shows unique application potential. In the synthesis of lithium-ion battery positive electrode materials, it can promote the formation of an ordered structure of layered oxide materials as a mineralizer, and improve the cycle stability of nickel-cobalt-manganese ternary materials by more than 30%. In the research and development of solid electrolytes, the complexation reaction of triisobutylaluminum with lithium borohydride can effectively reduce the interface impedance, and related research has entered the pilot stage. In addition, its application as a reducing agent in the preparation of hydrogen storage materials has also made breakthroughs. The nano-aluminum particles generated by controllable decomposition have an ultra-high specific surface area, which significantly improves the hydrogen absorption and desorption kinetics of the material.

From the analysis of product performance advantages, the core competitiveness of Triisobutylaluminum is reflected in the exquisite balance between reactivity and selectivity. Compared with other alkyl aluminum compounds, the steric hindrance effect in its molecular structure can not only ensure sufficient reactivity, but also effectively inhibit the occurrence of side reactions. This characteristic is particularly prominent in α-olefin polymerization, which can extend the life of the catalyst active center to several hours, while controlling the amount of oligomers generated to less than 0.5%. In addition, Triisobutylaluminum has excellent compatibility with different transition metals, and can form an efficient catalytic combination from traditional Ziegler-Natta catalysts to new post-transition metal systems. This wide applicability has always maintained an important position in the iteration of catalyst technology.

Thermodynamic stability is another significant advantage of this product. In the typical polymerization temperature range of 80-120°C, the decomposition rate constant of Triisobutylaluminum is two orders of magnitude lower than that of triethylaluminum, which means that there is no need to frequently add co-catalysts during continuous production, which reduces raw material consumption and improves process stability. This thermal stability is due to the strong electron-donating effect of the isobutyl group, which effectively stabilizes the positive charge of the aluminum center through hyperconjugation, increasing the decomposition activation energy to more than 150 kJ/mol. At the same time, its moderate volatility facilitates the precise control of the concentration gradient in the gas phase reaction system, which is of great significance for the preparation of polymer alloy materials with gradient structures.

In terms of process compatibility, Triisobutylaluminum exhibits excellent industrial application characteristics. Its liquid physical form is convenient for pipeline transportation and metering control, and its viscosity (0.8 mPa·s at 25℃) is similar to that of common hydrocarbon solvents, which can achieve rapid mixing and dispersion. In a continuous production device, its online mixing efficiency with the main catalyst can reach 99.8%, which is significantly better than the solid co-catalyst system. This fluidity advantage is also reflected in the waste liquid treatment link. The program temperature-controlled hydrolysis technology can achieve efficient recovery of aluminum elements, and the by-product isobutane can be recycled as a raw material. The atomic economy of the overall process exceeds 90%.

The continuous improvement of safety performance has strengthened the market competitiveness of this product. The modified Triisobutylaluminum derivatives developed by modern technology through molecular modification can increase the autoignition temperature to above 60°C while maintaining catalytic activity, significantly broadening the temperature window for storage and transportation. The application of microencapsulation technology enables it to exist in the form of solid particles, and the active ingredients are released by mechanical crushing during use. This innovative dosage form reduces the operational risk by 70%. In addition, the successful development of a new stabilizer formula reduces the hydrolysis sensitivity by two orders of magnitude, and can maintain stability for more than 8 hours even in an environment with a relative humidity of 30%, greatly improving the convenience of use.

In the catalytic process, Triisobutylaluminum can significantly reduce the activation energy of the reaction as an electron donor, reducing the polymerization temperature from 200°C to below 80°C, and reducing the energy consumption per unit product by 40%. Life cycle assessment shows that the polyolefin production line using this co-catalyst reduces carbon dioxide equivalent emissions by 25% compared with traditional processes. This environmental benefit has important strategic value in the context of carbon tariff policies.

Contact Us

Product Package picture:

Related References:

chemicalbook-Triisobutylaluminum

Triisobutylaluminum Manufacturer

Contact Us

As an experienced Triisobutylaluminum manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Triisobutylaluminum CAS 100-99-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.