Triethylenediamine CAS 280-57-9

Manufacturer Triethylenediamine CAS 280-57-9

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Triethylenediamine

CAS: 280-57-9

MOQ: 1KG

Directory Guidance on Triethylenediamine

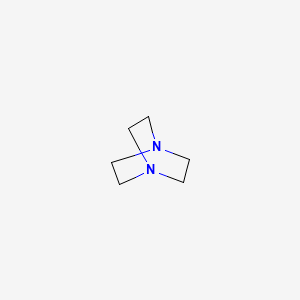

Chemical Structure

Basic Info:

| Melting point | 156-159 °C(lit.) |

| Boiling point | 174 °C |

| bulk density | 800kg/m3 |

| density | 1.02 g/mL |

| vapor pressure | 2.9 mm Hg ( 50 °C) |

| refractive index | n20/D 1.4634(lit.) |

Product Introduction:

Triethylenediamine, chemical name (1,4-diazabicyclo[2.2.2]octane), is an important organic compound. Its molecular formula is C₆H₁₂N₂, molecular weight is 112.18, white or light yellow crystals at room temperature, with a strong ammonia smell. This substance is very hygroscopic and deliquescent, and will absorb carbon dioxide and gradually turn yellow when exposed to air. At 25°C, its solubility in water is 45g/100g, and its solubility in ethanol is 77g/100g.

In terms of preparation, there are many methods for the synthesis of triethylenediamine. The common process is to use piperazine and its derivatives as raw materials and carry out ammonolysis reaction under the action of a catalyst. This method is mature, has a high product yield, and has been industrialized. In addition, triethylenediamine can be prepared by catalytic reaction of aqueous solution of other amine or alcohol amine compounds under specific conditions. This compound has a wide range of applications in many fields due to its unique chemical structure and properties.

Triethylenediamine plays an important role in the industrial field. It is a key catalyst in the production of polyurethane foam and is widely used in the manufacturing process of soft, semi-rigid and rigid polyurethane foam. In addition, it is also used as an accelerator for epoxy resin curing, which can accelerate the curing reaction of epoxy resin and improve production efficiency. It can also be used as a catalyst for the polymerization of monomers such as ethylene and acrylonitrile, and as an additive in cyanide-free electroplating to improve the quality and performance of electroplating. Its derivatives can also be used as corrosion inhibitors and emulsifiers, etc., and its application range is very wide.

However, it has certain dangers. It is strongly alkaline, and its vapor is irritating to the eyes, nostrils, throat and respiratory organs, and may cause health problems such as allergies and asthma. Therefore, it needs to be used and stored with extreme caution. It should be sealed and stored in a dry, cool, ventilated warehouse to avoid contact with acidic substances to prevent chemical reactions. If Triethylenediamine accidentally comes into contact with the skin or eyes, rinse immediately with plenty of running water and seek medical attention in time.

Nature and Specifications:

| Item | Specification |

| Product Name | Triethylenediamine |

| CAS No. | 280-57-9 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 198 °F |

| storage temp. | Store below +30°C. |

| solubility | 400g/l |

| form | Hygroscopic Crystals |

| pka | 3.0, 8.7(at 25℃) |

| color | White to pale yellow |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Core catalysts in the polyurethane industry

The most notable application of triethylenediamine is as a gel catalyst for polyurethane (PU) foam. In the preparation of soft, semi-rigid and rigid polyurethane foams, it significantly improves the reaction efficiency by catalyzing the gel reaction and foaming reaction of polyols and isocyanates. Especially in the one-step foaming process, triethylenediamine, due to its high activity and selectivity, can balance the foaming rate and material molding stability, reduce the amount of catalyst, and improve the open-cell structure and mechanical properties of the foam. In addition, its application in polyurethane elastomers, coatings and sealants is also becoming increasingly widespread.

Multi-field catalysis and functional material synthesis

In the chemical industry, triethylenediamine is not only a catalyst for the polymerization of ethylene oxide and acrylonitrile, but also can be used in the curing reaction of epoxy resin to improve the cross-linking efficiency of materials. Its derivatives are used as initiators in pesticide synthesis and as hydrogen-free electroplating additives in the electroplating industry to optimize the environmental friendliness of the process. In recent years, as an organic base catalyst for the Baylis-Hillman reaction, it has shown unique advantages in the synthesis of fine chemicals, such as the efficient catalysis of the reaction of aldehydes and acrylamide in an aqueous system, providing a new route for the green synthesis of nitrogen-containing heterocyclic compounds.

Cross-application of biochemistry and materials science

In the biomedical field, triethylenediamine is used as an anti-fading agent for fluorescence microscopy, which prolongs the development time of fluorescent dyes by scavenging free radicals. Its complexes with metal organic compounds (such as trimethylaluminum complexes) show controllable reactivity in catalytic reactions, providing new ideas for the development of asymmetric catalytic ligands. In addition, in the study of positive electrode materials for sodium-ion batteries, derivatives of triethylenediamine have been explored for optimizing the stability and electrochemical performance of electrode materials.

Efficient catalysis and selectivity

The cage structure of triethylenediamine makes it highly active and selective in the catalytic process. For example, in polyurethane foaming, it can accelerate the gelation and foaming reactions at the same time, but it shows a stronger catalytic tendency for the hydroxyl reaction of polyols and isocyanates, thereby precisely controlling the material properties. Compared with traditional amine catalysts, its dosage can be reduced by 30%-50%, significantly reducing production costs.

Process environmental protection and sustainability

Breakthroughs in synthesis technology in recent years have further enhanced its industrial value. For example, the monoethanolamine conversion process using small-grain zeolite catalysts can achieve highly selective triethylenediamine synthesis under normal pressure and carrier gas-free conditions, with extremely low byproduct piperazine production, and the mother liquor can be recycled, greatly reducing wastewater discharge. This green process is in line with the global chemical industry’s carbon reduction trend and promotes its large-scale application in the manufacture of fine chemicals.

Multifunctionality and derivative application expansion

The chemical modifiability of triethylenediamine provides a broad space for the development of its derivatives. For example, as a corrosion inhibitor, it can extend the life of metal equipment, and as an emulsifier, it can optimize the stability of petroleum additives. In the pharmaceutical field, it participates in the preparation of light-stable materials as an organic synthesis intermediate, expanding the application scenarios of functional polymer materials. In addition, its potential application in dye laser packaging and high-temperature electrochemical devices is becoming a research hotspot in materials science.

Contact Us

Product Package picture:

Related References:

chemicalbook-Triethylenediamine

Triethylenediamine Manufacturer

Contact Us

As an experienced Triethylenediamine manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Triethylenediamine CAS 280-57-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.