Titanium Tetrachloride CAS 7550-45-0

Factory wholesale Titanium Tetrachloride CAS 7550-45-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Titanium Tetrachloride

CAS: 7550-45-0

MOQ: 1KG

Directory Guidance on Titanium Tetrachloride

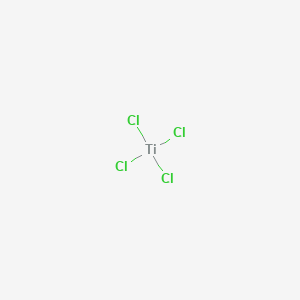

Chemical Structure

Basic Info:

| Melting Point | −25 °C(lit.) |

| Boiling Point | 135-136 °C(lit.) |

| Density | 1.73 g/mL at 20 °C(lit.) |

| Vapor Pressure | 50 mm Hg ( 55 °C) |

| Refractive Index | 1.61 |

| Fp | 46 °F |

Titanium Tetrachloride Introduction:

Titanium Tetrachloride (TiCl4) is an important inorganic compound. At room temperature it appears as either colorless or pale yellow liquid and exudes an unpleasant odor; its molecular structure features four covalent bonds between four titanium atoms bonded through covalent bonds to four chlorine atoms at its center, yielding approximately 189.68 molecular weight; its boiling point stands at 136.4 while melting point stands at -24.8, density being 1.726 g/cm3. Being +4 in terms of its oxidation state Titanium Tetrachloride shows great chemical activity; especially under conditions where high temperatures or moisture contact occur rapidly hydrolyses to form titanium dioxide (TiO2) and hydrogen chloride (HCl).

Titanium Tetrachloride must be stored and transported under conditions free of moisture; typically sealed steel cylinders or glass containers are employed and operated under dry inert gas protection. Titanium Tetrachloride production involves reacting ilmenite or rutile with chlorine gas at high temperatures; during this process both reaction temperature and gas flow rate must be strictly managed to guarantee purity in the final product.

Titanium Tetrachloride exhibits strong physical properties; its volatile nature causing white smoke in the air as a typical manifestation of hydrolysis products is evident from its volatile vapors. Titanium Tetrachloride poses both unique and operational challenges to its applications, such as use in laboratories. For example, when handling Titanium Tetrachloride it must be handled using either an inert gas glove box or vacuum system in order to avoid interference from environmental humidity. Chemically speaking, it acts as a Lewis acid and coordinates with various organic or inorganic ligands to form stable complexes – an action with immense utility in the fields of catalysis and material synthesis. Titanium Tetrachloride can also be reduced with hydrogen at high temperatures to produce metallic titanium, an integral step in producing sponge titanium by the Klauer process and an important link in the titanium metal industry chain.

Titanium Tetrachloride requires special consideration due to its toxic and corrosive qualities, as prolonged exposure may lead to respiratory tract damage and skin burns, necessitating protective equipment and ventilation facilities in industrial applications. Environmentally speaking, discharging Titanium Tetrachloride’s hydrolysis product hydrogen chloride untreated will lead to soil acidification and water pollution. Modern production processes rely on alkaline liquid absorption towers to neutralize tail gas emissions, with unreacted chlorine gas recovered via circulation systems for recycling. This not only reduces environmental risks but also optimizes resource usage. Thanks to technological innovations, mass production of Titanium Tetrachloride has progressed steadily towards being sustainable.

Nature and Specifications:

| Item | Specification |

| Product Name | Titanium Tetrachloride |

| CAS No. | 7550-45-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Storage Temp. | Flammables Area |

| Solubility | H2O: soluble |

| Form | Solution |

| Color | Light Yellow to Dark Brown |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Titanium Tetrachloride

Titanium Tetrachloride has an indispensable role as a fundamental chemical raw material across numerous industrial applications. When producing polyolefins, Ziegler-Nata catalysts contain complexes of Titanium Tetrachloride and alkyl aluminum; this type of catalyst effectively controls polymerization reactions of propylene or ethylene which ultimately dictate molecular weight distribution and stereoregularity of polyethylene or polypropylene production.

Titanium Tetrachloride’s coordination environment can be modified to precisely control mechanical and thermal stability of polymerization products that will meet varying customer demands, from food packaging to automotive components. Titanium Tetrachloride has become an integral component of the titanium metal smelting industry for producing sponge titanium through magnesium thermal reduction or sodium thermal reduction, before melting and casting to form titanium ingots used in high-end fields like aerospace and medical devices. In this process, its purity directly affects the mechanical strength and corrosion resistance of the final titanium material. Therefore, its distillation purification technology has always been the focus of industry research.

Titanium Tetrachloride is in high demand in organic synthesis. Acting as a strong Lewis acid, it is capable of catalyzing classic Fourier alkylation and acylation reactions with impressive selectivity and efficiency, especially those involving carbon-carbon bonds or heteroatom bonds being formed. Titanium Tetrachloride can also be combined with chiral ligands to achieve asymmetric catalysis which allows pharmaceutical intermediate synthesis with specific stereoconfigurations to take place more easily; additionally it can also prepare titanate ester compounds widely used in coatings, plastic additives and ceramic biners

Titanium Tetrachloride remains in high demand within the electronics industry, driving semiconductor manufacturing processes. When applied as part of plasma enhanced chemical vapor deposition (PECVD) technology, Titanium Tetrachloride creates diffusion barrier layers or metallization layers for integrated circuits to increase reliability and electrical conductivity.

Titanium dioxide nanoparticles produced through hydrolysis of Titanium Tetrachloride solution are used in photovoltaic applications to make photoanodes for dye-sensitized solar cells, with their porous structure and high specific surface area aiding photoelectric conversion efficiency. With flexible electronic devices becoming popular, their application potential in printed electronics such as transparent conductive films preparation through inkjet printing technology has also garnered much interest.

The Advantages Of Titanium Tetrachloride

The core advantage of Titanium Tetrachloride is first reflected in its unique thermodynamic properties. Compared with other metal chlorides, the low viscosity (0.827 mPa·s, 25℃) and high diffusion coefficient of Titanium Tetrachloride in the liquid state give it more advantages in the gas mass transfer process, and it is particularly suitable for the thin film preparation process that requires rapid and uniform deposition. Meanwhile, its wide liquid-phase temperature range (-24.8℃ to 136.4℃) provides flexible options for reaction systems under different temperature conditions. It can be used as a solvent medium in low-temperature environments as well as remain stable and participate in reactions at high temperatures.

From the analysis of chemical reaction activity, the strong Lewis acidity of Titanium Tetrachloride makes it irreplaceable in the field of catalysis. Its empty d orbital can effectively accept electron pairs and form intermediates with a variety of organic substrates, thereby reducing the activation energy of the reaction.

The continuous optimization of the production process has further strengthened the market competitiveness of Titanium Tetrachloride. Modern chlorination methods employ fluidized bed reactors, which increase the contact area between titanium ore and chlorine gas by 3 to 5 times and raise the reaction efficiency to over 95%. The application of multi-stage distillation columns can stably control the purity of products above 99.99%, meeting the strict requirements of semiconductor-grade materials. In addition, the popularization of closed-loop systems has enabled the chlorine gas utilization rate to reach 98%, reducing energy consumption by approximately 30% compared to traditional processes, and simultaneously cutting the discharge of the three wastes to one fifth of the original.

The wide range of applications constitutes another major advantage of Titanium Tetrachloride. From traditional metallurgy to emerging nanotechnology, their functional attributes can be developed in multiple dimensions. For example, in the field of energy storage, titanium-based materials derived from Titanium Tetrachloride (such as lithium titanate) are used as the anode of lithium-ion batteries, featuring zero strain characteristics and an extremely long cycle life; In the field of environmental protection, its hydrolysis product titanium dioxide, as a photocatalyst, can efficiently degrade organic pollutants. This interdisciplinary application possibility makes it a bond connecting basic chemical engineering and high-tech industries.

The improvement of environmental compatibility is also worthy of attention. By improving the production process, modern enterprises have achieved the recycling and reuse of more than 90% of the by-products in the production process of Titanium Tetrachloride. Hydrogen chloride produced by hydrolysis can be made into hydrochloric acid and returned to the production chain, while titanium dioxide by-products are sold as white pigments or sunscreen raw materials. This circular economy model not only reduces the environmental burden, but also creates additional economic benefits, reducing the comprehensive production cost of Titanium Tetrachloride by more than 40% compared with ten years ago.

From the perspective of market development prospects, the growth in demand for Titanium Tetrachloride is highly consistent with emerging industries. The global construction of 5G base stations has driven up the demand for titanium nitride films in high-frequency communication devices, and the new energy vehicle industry has promoted the capacity expansion of lithium titanate batteries. All these will continue to enhance its market valuation. Meanwhile, the emergence of new preparation technologies such as plasma chlorination is expected to further reduce the production cost by 20%, paving the way for the penetration and application of Titanium Tetrachloride in more fields.

Contact Us

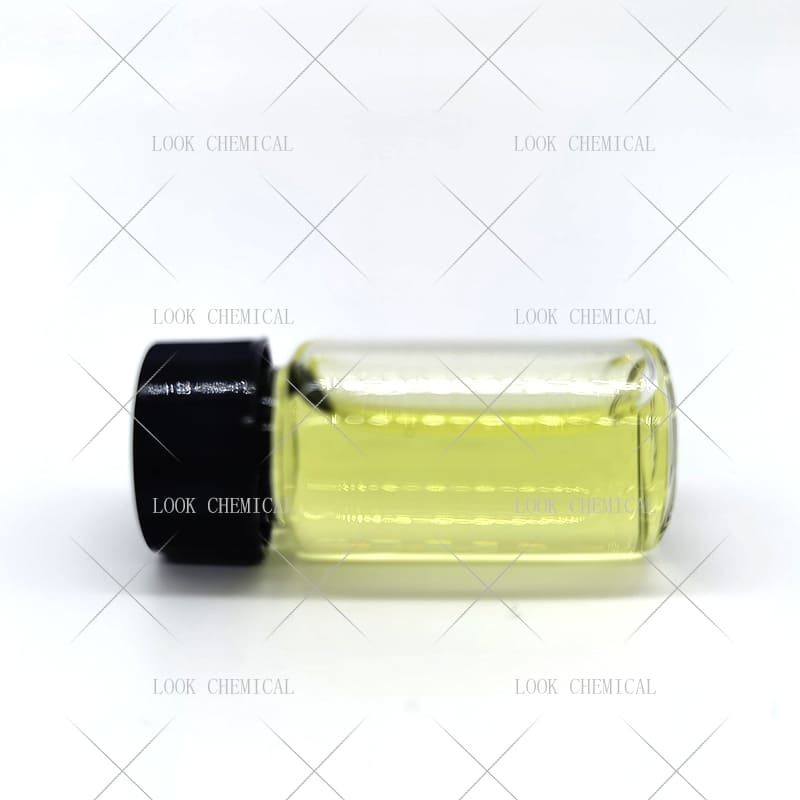

Product Package picture:

Related References:

chemicalbook-Titanium Tetrachloride

Titanium Tetrachloride Manufacturer

Contact Us

As an experienced Titanium Tetrachloride manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Titanium Tetrachloride CAS 7550-45-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.