Tetrabromobisphenol A CAS 79-94-7

Free Sample Tetrabromobisphenol A CAS 79-94-7

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Tetrabromobisphenol A

CAS:79-94-7

MOQ: 1KG

Directory Guidance on Tetrabromobisphenol A

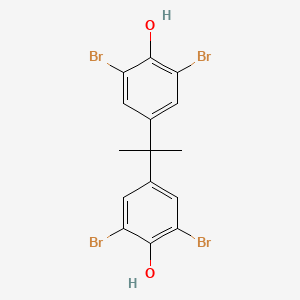

Chemical Structure

Basic Info:

| Melting point | 178-181 °C(lit.) |

| Boiling point | 316 °C |

| density | 2.1 |

| vapor pressure | 0Pa at 20℃ |

| refractive index | 1.5000 (estimate) |

| storage temp. | 2-8°C |

Product Introduction:

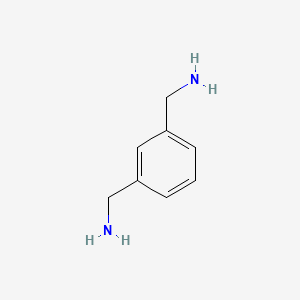

Tetrabromobisphenol A (TBBPA for short) is a common bromine-based flame retardant with a chemical formula of C₁₅H₁₂Br₄O₂ and a molecular weight of about 543.87. It is a white to light yellow crystalline powder with a high melting point, generally between 178°C and 181°C, and a boiling point of 316°C. It has a high density of about 2.18 g/cm³, and is insoluble in water at room temperature, but soluble in organic solvents such as methanol and ether. This substance has good flame retardant properties due to its high bromine content (theoretical bromine content is about 58.77%) and is widely used in various industrial fields.

In terms of use, Tetrabromobisphenol A is mainly used as a reactive flame retardant, which can covalently bond with the polymer structure to improve the flame retardant properties of the material. It can be used to manufacture materials such as bromine-containing epoxy resins and tetrabromobisphenol A polycarbonate, and is widely used in the electronic and electrical industry, such as the production of circuit boards, computers, televisions and other products. In addition, it can also be used as an additive flame retardant in materials such as acrylonitrile-butadiene-styrene (ABS) plastics, high-impact polystyrene (HIPS), unsaturated polyester resins, and rigid polyurethane foams to enhance their fire resistance.

However, Tetrabromobisphenol A also has certain environmental and health risks. It has high hydrophobicity and bioaccumulation potential, can be enriched in organisms, and may have toxic effects on aquatic organisms. During combustion, it releases toxic gases and a large amount of smoke, which is harmful to the environment and human health. Therefore, when using and handling it, it is necessary to strictly abide by relevant safety regulations and environmental protection requirements, and take appropriate protective measures to reduce its potential risks to the environment and human health.

In addition, the preparation of Tetrabromobisphenol A is usually obtained by reacting bromoterephthalic anhydride and bisphenol A. As an important industrial chemical, it has broad market application prospects, especially in the fields of electronics and building materials. However, as people’s attention to environmental protection and sustainable development continues to increase, more research and development work may be devoted to finding more environmentally friendly and efficient alternative flame retardants in the future to reduce dependence on traditional brominated flame retardants.

Nature and Specifications:

| Item | Specification |

| Product Name | Tetrabromobisphenol A |

| CAS No. | 79-94-7 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| solubility | Insoluble |

| pka | 8.50±0.10(Predicted) |

| color | White to Almost white |

| Water Solubility | Insoluble |

| BRN | 1889048 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Tetrabromobisphenol A (TBBPA) is an important bromine-based flame retardant. It has been widely used in many fields due to its efficient flame retardant properties and good thermal stability. Its application in the electronic and electrical industry is particularly prominent. It is mainly used to produce bromine-containing epoxy resins, which are widely used in the manufacture of printed circuit boards, such as the common FR-4 copper clad laminate. By adding Tetrabromobisphenol A, the fire resistance of the circuit board has been significantly improved, thereby effectively ensuring the safety of electronic equipment.

Tetrabromobisphenol A also plays an important role in the housing and internal components of electronic equipment. As an additive flame retardant, it is widely used in epoxy resin sealants, adhesives and packaging materials, enhancing the flame retardancy and stability of these materials. This application not only improves the overall safety of electronic equipment, but also extends the service life of the product.

In the field of building materials, Tetrabromobisphenol A is also indispensable. It is widely used in the insulation layer of plastic pipes, wires and cables, and the production of flame-retardant polyurethane foam plastics. By adding this product, the fire resistance of these materials has been significantly improved, which effectively reduces the risk of fire and ensures the overall safety of the building.

In the automotive industry, it is also widely used. It is used in the manufacture of automotive interior parts and components, such as seats, dashboards and door interiors. By adding Tetrabromobisphenol A, the flame retardant properties of these parts have been significantly enhanced, reducing the burning speed and smoke generation when a fire occurs. In addition, in the field of new energy vehicles, it is also used in the manufacture of battery pack shells and internal insulation materials, further improving the safety of the car.

In the textile industry, Tetrabromobisphenol A is also widely used. It is used to produce flame-retardant textiles, such as fire suits, home decoration fabrics and automotive interior fabrics. These textiles have significantly improved their flame retardant rating by adding Tetrabromobisphenol A, while maintaining their original performance. With the continuous improvement of people’s awareness of fire safety and the increasingly stringent relevant regulations, the market demand for flame-retardant textiles is also increasing.

First, Tetrabromobisphenol A has excellent flame retardant properties. It contains a high bromine content, which can effectively inhibit the spread of flames and the burning speed. In the electronic and electrical industry, it is widely used to manufacture printed circuit boards (such as FR-4 copper clad boards), and significantly improves the fire resistance of circuit boards by chemically bonding with resins. In addition, it is also used in a variety of engineering plastics, such as ABS, HIPS, etc., as an additive flame retardant, which can effectively reduce the flammability of these materials.

Secondly, Tetrabromobisphenol A has good thermal stability. Its melting point is between 178℃ and 181℃, and its decomposition temperature is as high as 316℃. This property enables it to remain stable in high temperature environments and will not easily decompose or fail, thereby ensuring the safety of the material during processing and use.

Furthermore, Tetrabromobisphenol A has a high performance-price ratio. As an efficient flame retardant, it can achieve good flame retardant effects at a lower addition amount, thereby reducing production costs. This gives it a clear price advantage in market competition, especially for large-scale production of electronic and electrical products and building materials.

In addition, Tetrabromobisphenol A has the characteristics of good chemical stability. It is very stable when stored and used at normal ambient temperature and is not prone to dangerous reactions with other substances. This stability enables it to maintain good performance in various complex industrial production environments and reduces safety hazards caused by chemical reactions.

Tetrabromobisphenol A is also an important intermediate. It can be used to synthesize other flame retardants, such as brominated epoxy resins, brominated polycarbonates, etc. These derivatives further expand its application range, allowing it to play a flame retardant role in different materials and products.

Finally, Tetrabromobisphenol A is relatively safe in terms of environment and health. Although it produces toxic gases when burned, it has little harm to the environment and human health under normal conditions of use. The European Union has conducted a comprehensive hazard assessment on it, and the results show that it has no obvious harm to the environment and human health as a reactive or additive flame retardant.

Contact Us

Product Package picture:

Related References:

chemicalbook-Tetrabromobisphenol A

Tetrabromobisphenol A Manufacturer

Contact Us

As an experienced Tetrabromobisphenol A manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Tetrabromobisphenol A CAS 79-94-7 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.