Tert-Butyl Peroxybenzoate CAS 614-45-9

Factory wholesale Tert-Butyl Peroxybenzoate CAS 614-45-9

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Tert-Butyl Peroxybenzoate

CAS: 614-45-9

MOQ: 1KG

Directory Guidance on Tert-Butyl Peroxybenzoate

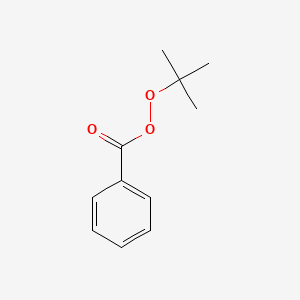

Chemical Structure

Basic Info:

| Melting point | 8 °C |

| Boiling point | 75-76 °C/0.2 mmHg (lit.) |

| density | 1.021 g/mL at 25 °C (lit.) |

| vapor density | 6.7 (vs air) |

| vapor pressure | 3.36 mm Hg ( 50 °C) |

| refractive index | n20/D 1.499(lit.) |

Product Introduction:

Tert-Butyl Peroxybenzoate (TBPB) is an important organic peroxide compound with a molecular formula of C11H14O3, belonging to the peroxyester initiator. Its structure contains benzoic acid groups and tert-butyl peroxide groups. This unique chemical configuration gives it high thermal stability and controllable decomposition characteristics. As a free radical initiator, TBPB is usually a colorless or light yellow liquid at room temperature with a slight pungent odor, a density of about 1.04 g/cm³, a boiling point in the range of 80-90℃ (0.1 kPa), and a flash point above 60℃, showing a certain flammability risk.

From the perspective of chemical synthesis, Tert-Butyl Peroxybenzoate is mainly prepared by the esterification reaction of benzoyl chloride and tert-butyl hydroperoxide under alkaline conditions. The process requires strict control of reaction temperature and feed ratio to ensure product purity and reduce the occurrence of side reactions. The purity of industrial-grade Tert-Butyl Peroxybenzoate is usually required to reach more than 98%, and the impurity content must meet relevant safety standards. In terms of decomposition behavior, the half-life of TBPB is closely related to the temperature environment in which it is located. For example, its half-life is about 10 hours at 100°C, while it is shortened to about 1 hour at 130°C. This temperature-dependent characteristic enables it to accurately control the free radical generation rate under specific process conditions, thereby adapting to the needs of different polymerization reactions.

As a typical representative of the organic peroxide family, the safety management of Tert-Butyl Peroxybenzoate must follow strict operating specifications. Its decomposition products mainly include carbon dioxide, carbon monoxide, benzoic acid and alkanes, which may corrode equipment or induce secondary reactions. Therefore, in industrial applications, complete safety protection facilities are required, including temperature monitoring systems, emergency pressure relief devices and exhaust gas treatment units. From a toxicological perspective, Tert-Butyl Peroxybenzoate is irritating to the skin and mucous membranes. Long-term exposure may cause respiratory inflammation. Therefore, operators need to be equipped with professional protective equipment and the working environment must be well ventilated.

Nature and Specifications:

| Item | Specification |

| Product Name | Tert-Butyl Peroxybenzoate |

| CAS No. | 614-45-9 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 200 °F |

| storage temp. | 2-8°C |

| solubility | water: soluble1.18g/L |

| form | Liquid |

| color | Clear yellow |

| Odor | mild aromatic odor |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The curing of unsaturated polyester resin (UPR) is another important application scenario of Tert-Butyl Peroxybenzoate. As a low-temperature curing accelerator, TBPB can form a synergistic effect with cobalt-based accelerators to effectively reduce the resin gel time in the range of 60-100°C. This property gives it a significant advantage in the lamination process of large composite products (such as wind turbine blades and ship hulls), which can not only ensure sufficient operating time for layering operations, but also quickly complete the curing cycle by heating. At the same time, TBPB will not cause excessive shrinkage of the resin during the curing process, which helps to maintain the dimensional stability of the product.

The demand for Tert-Butyl Peroxybenzoate in the coatings and adhesives industry mainly stems from its unique performance in UV curing systems. As an auxiliary component of photoinitiators, TBPB can expand the temperature adaptability range of the curing system, especially in thick coatings or formulations with high pigment content, which can make up for the shortcomings of pure photoinitiators in deep curing. In the fields of automotive original paint, industrial anti-corrosion coatings, etc., this dual curing mechanism significantly improves the crosslinking density and weather resistance of the coating. In addition, in the continuous coating process of pressure-sensitive adhesives, the precise decomposition characteristics of Tert-Butyl Peroxybenzoate help to achieve a balance between the cohesive strength and adhesion properties of the adhesive layer.

The rubber vulcanization field is one of the traditional markets for TBPB applications. In the vulcanization process of synthetic rubbers such as EPDM and NBR, Tert-Butyl Peroxybenzoate, as an important component of peroxide vulcanizers, can provide a stable free radical flow and promote C-C crosslinking between rubber molecular chains.

In the field of electronic material packaging, the application value of Tert-Butyl Peroxybenzoate is reflected in its precise control of the epoxy resin curing process. By adjusting the ratio of TBPB to amine curing agents, the gradient control of the curing rate can be achieved, which is particularly important for the layer-by-layer packaging process of multi-layer circuit boards. In high-performance materials such as semiconductor packaging glue and LED packaging resin, the free radical reaction initiated by TBPB can effectively reduce the curing stress and reduce the generation of microcracks inside the device. At the same time, the low corrosiveness of its decomposition products also meets the strict requirements of electronic components for purity.

The demand for Tert-Butyl Peroxybenzoate in the environmental protection industry has been on the rise in recent years, mainly in the field of wastewater treatment. As an oxidant precursor for advanced oxidation processes (AOPs), TBPB can be decomposed to produce hydroxyl radicals (·OH) under the action of specific catalysts. This type of strong oxidant can effectively degrade difficult-to-decompose organic matter in water bodies, such as drug residues, dye intermediates and other pollutants. Compared with the traditional Fenton reagent, the TBPB system has the advantages of a wide pH adaptability range and less iron sludge generation, providing a new technical path for industrial wastewater treatment.

The balance between thermal stability and storage safety is the most significant product advantage of Tert-Butyl Peroxybenzoate. Its decomposition activation energy is about 140 kJ/mol, which not only ensures chemical stability during storage at room temperature, but also ensures that the decomposition reaction can be quickly started at process temperature. Compared with similar products such as diisopropylbenzene peroxide (DCP), the critical storage temperature of TBPB is increased by about 5°C, which significantly reduces the temperature control energy consumption in the storage link. At the same time, its liquid physical form is convenient for precise metering and pipeline transportation, avoiding the risk of dust explosion in powdered peroxides, and is particularly suitable for continuous production processes with a high degree of automation.

In terms of reaction efficiency, Tert-Butyl Peroxybenzoate exhibits excellent free radical generation ability. This high efficiency allows TBPB to shorten the polymerization reaction time by 20-30% at the same addition amount, significantly improving production efficiency. In addition, the tert-butyloxy free radicals produced by its decomposition have moderate reactivity, which can effectively initiate monomer polymerization and will not cause chain transfer reaction due to excessive activity, which is conducive to obtaining high molecular weight and narrow distribution polymer products.

Environmental friendliness constitutes the differentiated competitive advantage of Tert-Butyl Peroxybenzoate. Its decomposition products do not contain elements such as sulfur and nitrogen that may cause secondary pollution, and the amount of benzoic acid generated is also controlled at the ppm level through process optimization. Under the EU REACH regulations and the global trend of green chemistry development, this clean decomposition characteristic makes TBPB the first choice to replace traditional sulfur-containing vulcanization systems. At the same time, the closed-loop synthesis process used in the production process can realize the recycling of solvents and unreacted raw materials, and the three wastes per unit product are reduced by more than 40% compared with similar products.

The product compatibility advantage is reflected in the wide applicability of Tert-Butyl Peroxybenzoate to a variety of resin systems. Whether it is a highly polar acrylic monomer or a non-polar styrene system, TBPB can maintain good solubility and dispersibility. This feature allows formulators to adapt to the needs of different product lines without frequently changing the initiator type, greatly shortening the research and development cycle of new products.

In terms of economic benefits, Tert-Butyl Peroxybenzoate has significant comprehensive cost advantages. Although its unit price is slightly higher than some traditional initiators, its high initiation efficiency allows the actual addition amount to be reduced by 15-20%, and the overall cost is balanced. In continuous production, the precise metering advantage brought by its liquid properties can reduce the loss of raw materials by 3-5%, and with the shortened reaction cycle, the unit energy consumption can be saved by 8-12%. From the perspective of the full life cycle cost analysis, TBPB has more prominent hidden benefits in reducing scrap rate and reducing equipment cleaning frequency, and is particularly suitable for high-end manufacturing fields with strict requirements on production stability.

Contact Us

Product Package picture:

Related References:

chemicalbook-Tert-Butyl Peroxybenzoate

Tert-Butyl Peroxybenzoate Manufacturer

Contact Us

As an experienced Tert-Butyl Peroxybenzoate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Tert-Butyl Peroxybenzoate CAS 614-45-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.