Polyethylene Glycol Diacrylate CAS 26570-48-9

Factory wholesale Polyethylene Glycol Diacrylate CAS 26570-48-9

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polyethylene Glycol Diacrylate

CAS: 26570-48-9

MOQ: 1KG

Directory Guidance on Polyethylene Glycol Diacrylate

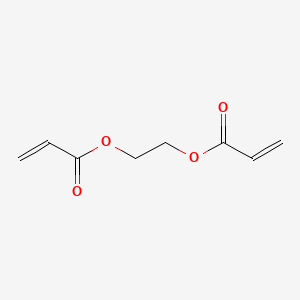

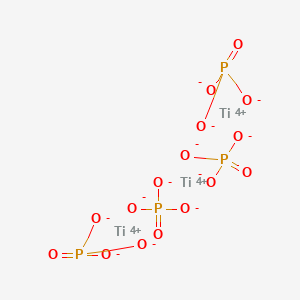

Chemical Structure

Basic Info:

| Melting Point | 12-17 °C |

| Density | 1.12 g/mL at 25 °C |

| Refractive Index | n20/D 1.47 |

| Fp | 347 °F |

| Storage Temp. | -20°C |

Polyethylene Glycol Diacrylate Introduction:

Polyethylene Glycol Diacrylate (PEGDA) is a polymer compound formed by functionalizing both ends of the polyethylene glycol (PEG) main chain with acrylate groups. Its molecular structure contains both hydrophilic polyether segments and cross-linkable acrylate double bonds. This unique chemical design makes it water-soluble, controllable cross-linking ability and excellent biocompatibility.

Chemically speaking, Polyethylene Glycol Diacrylate can be made by reacting polyethylene glycol with either acryloyl chloride or acrylic anhydride to form its esterification reaction and subsequent esterification reaction with acrylic anhydride or chloride. Temperature, catalyst dosage and reaction time must all be tightly managed to ensure uniform molecular weight distribution and intact double bonds during this step of production. Thanks to its wide molecular weight range (from hundreds to tens of thousands Daltons), researchers can manipulate physical and chemical properties including swelling, mechanical strength degradation rate etc by selecting PEG precursors with different chain lengths from different chain length precursors during this step of chemical synthesis.

Polyethylene Glycol Diacrylate is an ideal material to create hydrogels because its photocurable or thermosetting nature enables rapid three-dimensional network formation when exposed to ultraviolet light or free radical initiators, providing rapid formation of porous structures inside them that not only store lots of water but can also introduce functional groups through chemical modification for controlled release of drugs, cells or biomolecules.

The ether bond structure of Polyethylene Glycol Diacrylate gives it good flexibility, while the acrylate group provides sufficient reaction sites to enable it to form stable covalent connections with other biomolecules such as proteins and polysaccharides. In the solution state, Polyethylene Glycol Diacrylate exhibits typical Newtonian fluid behavior, but as the degree of cross-linking increases, its rheological properties will change to elastomers.

From the perspective of material stability, Polyethylene Glycol Diacrylate exhibits low nonspecific protein adsorption characteristics in a physiological environment, which significantly reduces the risk of immune rejection when used in vivo. At the same time, its degradation products are mainly polyethylene glycol and acrylic acid. The former has been listed as a recognized safe substance by the US Food and Drug Administration (FDA), and the latter can be excreted from the body through metabolic pathways at low concentrations.This degradability not only meets the demand of modern materials science for environmentally friendly materials, but also provides the possibility for the development of temporary implant devices.

Nature and Specifications:

| Item | Specification |

| Product Name | Polyethylene Glycol Diacrylate |

| CAS No. | 26570-48-9 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Solubility | H2O: soluble |

| Form | Granular Solid |

| Color | White to off-white |

| Water Solubility | Soluble in water. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Polyethylene Glycol Diacrylate

The application of Polyethylene Glycol Diacrylate in the industrial field mainly focuses on the development of functional coatings and adhesives. Its low-viscosity liquid precursor property enables it to be evenly coated on the surface of metal, plastic or glass substrates. After UV curing, it forms a transparent protective layer that is wear-resistant and corrosion-resistant.

In microelectronics manufacturing, Polyethylene Glycol Diacrylate, as a component of dielectric materials or encapsulation agents, can effectively reduce the stress concentration inside the device. More importantly, by introducing nano-fillers (such as silica or carbon nanotubes), the electrical conductivity or thermal conductivity of composite materials can be significantly enhanced, which opens up new paths for the innovative design of flexible electronic devices.

In terms of the research and development of environmentally friendly materials, the exploration of Polyethylene Glycol Diacrylate based degradable plastics is continuously advancing, with the aim of achieving controllable decomposition of the material at the end of its service life through molecular design.

Polyethylene Glycol Diacrylate has become an indispensable tool in tissue engineering and regenerative medicine research. Its three-dimensional network structure mimics the extracellular matrix’s physical environment and serves as an optimal microenvironment for stem cell differentiation, with researchers successfully steering mesenchymal stem cells towards osteogenesis or adipogenesis by altering stiffness parameters of its hydrogel hydrogel matrix.

In the field of drug delivery systems, the sustained-release property of Polyethylene Glycol Diacrylate hydrogel is used to extend the action time of small molecule drugs, protein or nucleic acid drugs. For example, encapsulating anti-cancer drugs in temperature-sensitive PEGDA hydrogels can achieve local administration at the tumor site and reduce systemic toxicity.

In recent years, with the development of 3D printing technology, UV-curable Polyethylene Glycol Diacrylate has been more widely used in the development of bio-inks. Its rapid curing property makes it possible to construct complex tissue structures layer by layer.

At the level of scientific research and innovation, the composite application of Polyethylene Glycol Diacrylate with other smart materials shows great potential. The copolymerization of temperature-sensitive polymers (such as poly N-isopropyl acrylamide) with PEGDA can prepare hydrogels that undergo volume phase transitions in response to temperature changes.Such materials have important value in the field of intelligent controlled release systems or bionic actuators.

The development of photoresponsive Polyethylene Glycol Diacrylate materials has achieved remote light control and regulation of material properties by introducing photoisomeric groups such as azobenzene. In terms of basic research, scientists have utilized the tunable mechanical properties of PEGDA hydrogels to deeply explore the influence mechanism of the cellular mechanical microenvironment on gene expression and migration behavior. These findings provide a new perspective for understanding tissue development and disease occurrence.

The Advantages Of Polyethylene Glycol Diacrylate

Polyethylene Glycol Diacrylate has many significant advantages. It has good biocompatibility and hardly causes human immune and toxic reactions, which allows it to be safely used in the human body in the biomedical field and to have long-term contact with human tissues and cells without adverse effects, providing reliable protection for various medical applications.

In terms of stability, the three-dimensional network formed by the cross-linking of Polyethylene Glycol Diacrylate has excellent chemical stability and can maintain long-term stability in vivo, avoiding the risk of accidental disintegration of the material during in vivo application. Its degradation behavior is time-dependent and the products are non-toxic, which not only ensures the sufficient mechanical support time of the temporary scaffold material, but also eliminates the complications that may be caused by long-term retention.

From the perspective of industrial production, the synthetic route of Polyethylene Glycol Diacrylate is mature and the raw materials are readily available, making it suitable for large-scale continuous production. Compared with other synthetic polymer materials, the waste generated during its production process is easier to handle, which is in line with the development concept of green chemistry. In terms of economic benefits, although the production cost of high-purity medical-grade PEGDA is relatively high, its irreplaceability in high-end medical products keeps the input-output ratio advantageous.

The environmentally friendly property is another highlight that distinguishes Polyethylene Glycol Diacrylate from traditional petroleum-based polymer materials.Compared with traditional acrylic resins, the ether bond structure in the PEGDA main chain makes it easier to gradually decompose through hydrolysis in natural environments. In addressing the global challenge of microplastic pollution, this controllable degradation characteristic is particularly important.

A new type of degradable packaging material developed based on Polyethylene Glycol Diacrylate has entered the pilot production stage. Its mechanical properties are close to those of conventional plastics, but the environmental residue can be reduced by more than 80%. In terms of energy consumption, the light-curing property of PEGDA can save approximately 60% of energy compared to the thermal curing process, which provides a practical technical path for reducing the carbon footprint.

In terms of technological innovation potential, the chemical structure of Polyethylene Glycol Diacrylate provides abundant modification sites for its functional expansion. By introducing fluorescent groups, magnetic nanoparticles or conductive polymers into the molecular chain, intelligent material systems with multiple response characteristics can be developed. For example, the combination of upconversion nanoparticles and PEGDA can achieve near-infrared light-controlled drug release. This deep tissue penetration ability provides a new idea for non-invasive treatment.

Under the trend of interdisciplinary integration, the combination of Polyethylene Glycol Diacrylate with cutting-edge fields such as gene editing technology and organoid culture is giving rise to revolutionary biomanufacturing platforms. These innovative applications not only expand the value boundaries of the materials themselves, but also promote the technological upgrading of related industries.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Polyethylene Glycol Diacrylate

Polyethylene Glycol Diacrylate Manufacturer

Contact Us

As an experienced Polyethylene Glycol Diacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polyethylene Glycol Diacrylate CAS 26570-48-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.