Polycaprolactone CAS 24980-41-4

Polycaprolactone CAS 24980-41-4 With Top Selling

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polycaprolactone

CAS: 24980-41-4

MOQ: 1KG

Directory Guidance on Polycaprolactone

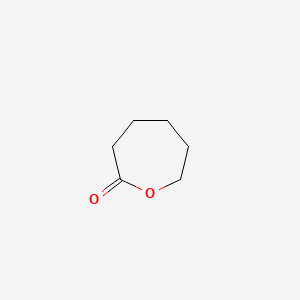

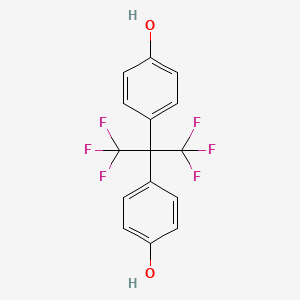

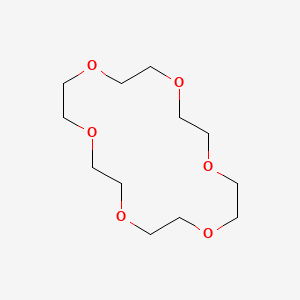

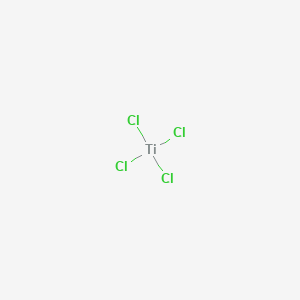

Chemical Structure

Basic Info:

| Melting point | 60 °C(lit.) |

| Tg | -60 |

| density | 1.146 g/mL at 25 °C |

| storage temp. | -20°C |

| form | pellets |

Product Introduction:

Polycaprolactone (PCL for short) is a polymer material with unique properties and wide applications. It is a polyester polymer compound synthesized by ring-opening polymerization of ε-caprolactone monomer under the catalysis of metal anion complex catalyst. Its molecular structure contains 5 non-polar methylene groups (—CH₂—) and a polar ester group (—COO—), which gives it good flexibility and biocompatibility.

Polycaprolactone is a semi-crystalline polymer with a low melting point, usually between 59°C and 64°C, and a glass transition temperature of about -60°C. Due to its low melting point and high crystallinity, it can be molded at lower temperatures, which gives it a significant advantage in industrial production.

One of the most prominent properties of polycaprolactone is its biodegradability. In the natural environment, it can be decomposed by microorganisms or enzymes, and the final products are carbon dioxide and water, which makes it an environmentally friendly material. In addition, it has good biocompatibility, which means that it does not cause significant toxicity or irritation in the body, and cells can grow normally on its scaffold.

Therefore, Polycaprolactone has been widely used in the medical field, such as as a drug carrier, tissue engineering scaffold, degradable suture, etc. Polycaprolactone also has shape memory function, which can deform under external force and return to its original shape under external conditions such as heating. This feature makes it also have potential application value in the field of smart materials.

Polycaprolactone has excellent processing performance and can be molded by a variety of methods, such as extrusion, injection molding, blow molding, solution spin coating, etc. It can be blended with other materials to improve its performance and function. For example, it can be blended with materials such as polylactic acid (PLA), gelatin, hydroxyapatite, etc. to prepare composite materials with specific properties.

Nature and Specifications:

| Item | Specification |

| Product Name | Polycaprolactone |

| CAS No. | 24980-41-4 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | -20°C |

| form | pellets |

| Odor | odorless |

| InChI | InChI=1S/C6H10O2/c7-6-4-2-1-3-5-8-6/h1-5H2 |

| InChIKey | PAPBSGBWRJIAAV-UHFFFAOYSA-N |

| SMILES | O1CCCCCC1=O |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Medical field

In the medical field, Polycaprolactone is widely used. It is used as a drug sustained-release carrier, which can encapsulate drugs in a polymer matrix. By adjusting the composition and structure of the polymer, it can achieve slow release of drugs, prolong the drug’s action time, and reduce the frequency of administration. In addition, PCL is also used to manufacture tissue engineering scaffolds. Its flexibility and processability enable it to be made into scaffold materials of various shapes, providing a good growth environment for cells and promoting tissue repair and regeneration. The absorbable sutures made of PCL can gradually degrade in the body, avoiding the trouble of traditional sutures requiring secondary surgery to remove, reducing the patient’s pain and infection risk. In addition, PCL can also be used to manufacture medical devices such as artificial joints and vascular stents. Its mechanical properties and biocompatibility can meet the use requirements of human joints.

Packaging field

Polycaprolactone has broad application prospects in the packaging field. As a biodegradable material, PCL can effectively reduce the pollution of packaging waste to the environment. PCL packaging materials can effectively isolate external oxygen, moisture and microorganisms, maintain the freshness and quality of food, and are therefore widely used in food packaging. In addition, PCL is also used in pharmaceutical packaging, which can protect drugs from the influence of the external environment and ensure the stability and safety of drugs. The degradability of PCL packaging materials also meets environmental protection requirements, making it widely used in daily necessities packaging, such as for packaging cosmetics, shampoo, shower gel, etc.

Agricultural field

Polycaprolactone also has important applications in the agricultural field. PCL mulch can effectively maintain soil moisture, increase soil temperature, and promote crop growth. Compared with traditional plastic mulch, PCL mulch can be naturally degraded after use, avoiding the pollution of soil by traditional mulch residues. In addition, PCL can also be used to make seed coating materials, provide necessary nutrition and protection for seeds, and improve seed germination rate and growth quality. Its degradability reduces pollution to the environment and meets the requirements of sustainable agricultural development.

Materials Science and Engineering

In the field of materials science and engineering, the application of Polycaprolactone is mainly reflected in its good processing performance and versatility. PCL is an ideal 3D printing material that can be made into filaments for the manufacture of various complex structures and models. In addition, PCL fibers are soft and comfortable, elastic and biodegradable, and can be used to manufacture high-end textiles and clothing. PCL can also be blended or compounded with other materials to prepare composite materials with special properties. For example, PCL and hydroxyapatite can be blended to make bone repair materials, further expanding its application range in the field of materials science.

Other fields

Polycaprolactone has also been used in some other fields. In the field of coatings, PCL, as a basic material or additive for coatings, can improve the performance and quality of coatings and broaden the application range of coatings. In addition, PCL has shape memory function, which can deform under external force and return to its original shape under external conditions such as heating. This feature makes it have potential application value in the field of smart materials, such as for the manufacture of deformable smart devices.

1. Biocompatibility and Biodegradability

Polycaprolactone offers excellent biocompatibility; cells can grow normally on its scaffold without experiencing significant toxic or irritating reactions. In addition, PCL can be decomposed in its natural environment through microorganisms or enzymes and breakdown into carbon dioxide and water as byproducts – making it an environmentally-friendly material which makes it perfect for medical and packaging fields.

2. Low Melting Point and High Crystallinity

Polycaprolactone has an ideal melting point range between 59degC and 64degC, with a glass transition temperature near -60degC. This low melting point enables PCL to be processed at lower temperatures – cutting energy consumption and processing costs considerably while creating opportunities to lower energy consumption in production lines. At the same time, PCL exhibits superior crystallinity properties such as creating rubber states at physiological temperatures, offering impressive viscoelastic properties.

3. Superior Processing Performance

Polycaprolactone can be easily processed using various techniques such as extrusion, injection molding, blow molding and solution spin coating. Thanks to its exceptional processing performance it can be formed into various forms including fibers, flakes and sheets which make it perfect for manufacturing surgical sutures, medical equipment and 3D printing materials.

4. Excellent Compatibility and Solubility

Polycaprolactone has excellent compatibility with various polymer materials (PE, PP, ABS and PC among others), which allows it to improve performance through blending or copolymerization. Furthermore, PCL exhibits good solubility in aromatic compounds, ketones and polar solvents further broadening its application range.

5. Customizable Degradation Rate

Polycaprolactone’s degradation rate can be easily customized through modification of its molecular weight and composition, providing it with the versatility required to meet various application scenarios – for instance long-term drug release in sustained-release systems. This customizability ensures it can meet this need while meeting different user needs in terms of drug release stability and release over time.

6. Economic and Sustainable

PCL offers economic and sustainable advantages when used for manufacturing purposes, thanks to its lower production costs and biodegradability that reduces pollution to the environment. These characteristics make PCL an excellent environmental-protection choice when replacing traditional non-degradable plastics.

Contact Us

Product Package picture:

Related References:

chemicalbook-Polycaprolactone

Polycaprolactone Manufacturer

Contact Us

As an experienced Polycaprolactone manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polycaprolactone CAS 24980-41-4 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.