Polyacrylic Acid CAS 9003-01-4

Free Sample Polyacrylic Acid CAS 9003-01-4

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polyacrylic Acid

CAS:9003-01-4

MOQ: 1KG

Directory Guidance on Polyacrylic Acid

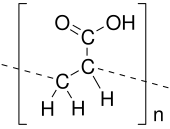

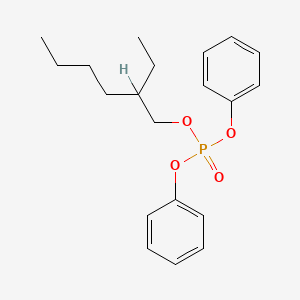

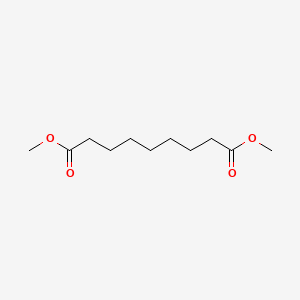

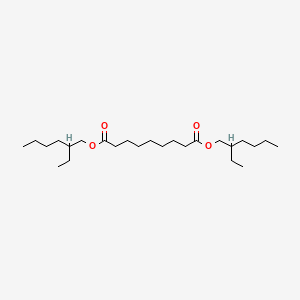

Chemical Structure

Basic Info:

| Melting point | 95 °C |

| Boiling point | 116 °C |

| density | 1.2 g/mL at 25 °C |

| Tg | 106 |

| vapor pressure | 2.64-3.57hPa at 20-25℃ |

Product Introduction:

Polyacrylic Acid is a kind of polymer formed by crosslinking acrylic acid with allyl sucrose or pentaerythritol, belonging to polyacrylic acid compounds. Its molecular structure contains a large number of carboxylic acid groups, and these active groups give the material unique swelling and viscosity regulation ability. As a water-soluble resin, carbomer is white powder in the dry state, and forms a three-dimensional network structure through hydrogen bonding after contact with water, thus showing remarkable thickening, suspension and stability characteristics. This unique physical and chemical properties make it an important functional raw material in medicine, cosmetics and industrial fields.

Chemically speaking, the crosslinking degree of Polyacrylic Acid directly impacts its swelling properties and viscosity range. Carbomers with lower crosslinking degrees are easier to swell up, which makes them suitable for creating highly transparent gel. High-crosslinked products are more suitable for applications where viscosity or shear-dilution characteristics are required, with Polyacrylic Acid viscosity being significantly influenced by pH value.

Industrial production of Polyacrylic Acid requires stringent control over its reaction conditions, including monomer proportions, initiator concentration and reaction temperature. By altering these variables to meet downstream needs for applications like Carbomer 934P-974P, products with various molecular weights and crosslinking degrees can be achieved – including variations in viscosity range, rheological properties and biocompatibility among models.

It is worth noting that the biosafety of Polyacrylic Acid has been certified by multiple international authoritative organizations, including the United States Pharmacopeia (USP), the European Pharmacopoeia (EP), and the International Dictionary of Cosmetic Ingredients (INCI). Its non-toxic, non allergenic, and low irritant characteristics make it widely used in the fields of medicine and cosmetics. In addition, Carbopol is biodegradable in the environment, meeting the demand for sustainable materials in modern industry and further promoting its popularity in the global market.

Nature and Specifications:

| Item | Specification |

| Product Name | Polyacrylic Acid |

| CAS No. | 9003-01-4 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | Powder |

| color | White |

| pH | 2.5 -3.0 (1% water solution) |

| Water Solubility | Soluble in water. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The application of Polyacrylic Acid in the pharmaceutical field is mainly used as a substrate material for local drug delivery systems. In this application, the gelation of Polyacrylic Acid is expected to improve the bioavailability of the drug by increasing the residence time of the drug on the skin or mucosal surface. Carbomer acts as a thickening agent and pharmaceutical agent in formulations to reduce patient discomfort by controlling the rate at which the active pharmaceutical ingredient AP is released from the formulations. Oral suspensions and ophthalmic preparations also have important application value. Its mechanism of action is mainly reflected in two aspects: in the suspension, carbomer acts as a suspension agent, so that the active component will not precipitate, so as to maintain a uniform dose; In eye drops, carbomer’s viscoelasticity helps reduce fluid loss during blinking, ultimately extending the effective life of the drug.

The personal care industry is another major application market for Polyacrylic Acid. In skin care products, carbomer is commonly used in serums, masks and sunscreens. The crystal clear gel-like structure it usually forms can enhance the touch of the product while keeping the active ingredient in the most stable state. In shampoos and body washes, carbomer acts as a rheological modifier to make formulations easier to pump and roll out.

The industrial demand for Polyacrylic Acid is mainly concentrated in the field of specialty coatings and adhesives. In water-based coatings, Polyacrylic Acid can prevent pigment settling and improve brushing performance by adjusting the rheology of the system. In pressure-sensitive adhesive applications, it can be used as a tackifier to enhance the initial adhesive strength and give the colloid weather resistance under the right conditions. Due to its suspension characteristics, Polyacrylic Acid can avoid dye aggregation, thereby improving the uniformity of dyeing, and is used to prepare high solid content color paste in textile printing and dyeing. It can also be used in the electronics industry to prepare conductive gels, which are used as heat dissipation materials or packaging materials for electronic components.

The application of Polyacrylic Acid in the field of agriculture is gradually emerging. For example, in pesticide controlled release formulations, carbomer gels can coat the active ingredient and slow its breakdown in the environment, thus extending the duration of action. Seed coating technology can use carbomer as a film forming agent, which can not only fix fungicides or nutrients, but also form a moisturizing layer to promote water absorption and germination of seeds. These novel applications demonstrate Kapom’s technological advantages in the modernization of traditional industries.

With the progress of nanotechnology, Polyacrylic Acid has become increasingly active in the application of new drug carriers and smart materials. For example, by linking carbomer to small particles, a Ph-responsive targeted drug delivery system can be built; In the field of bendable sensors, Kapomgi hydrogels can be made into sensing layers for wearable devices due to their high tensile and electrical conductivity. These important new attempts further expand the range of applications of Polyacrylic Acid and place it in an important position in future technological changes.

The main advantage of Polyacrylic Acid is its excellent rheological modification ability. Under static conditions, the formed gel structure can effectively suspend particles. When subjected to shear forces (applied or pumped), the viscosity of the system is rapidly reduced, thus improving the processing and use experience. This “shear thinning” characteristic gives it an irreplaceable advantage in the case of both storage stability and ease of use.

From a chemical stability point of view, Polyacrylic Acid has better electrolyte and organic solvent resistance than most natural thickeners. In addition, carbomol has good thermal stability and does not degrade significantly during high temperature sterilization (such as 121°C wet heat sterilization), which is essential for aseptic processes in pharmaceutical and cosmetic production.

In terms of biocompatibility, Polyacrylic Acid performs well. Its molecular structure does not contain any ingredients of animal origin, so it meets the requirements of both vegetarianism and religious culture. Toxicological studies have demonstrated that carbomer has no teratogenic or carcinogenic risk and does not cause cumulative skin irritation or mucosal damage. Such safety characteristics make it one of the preferred excipients in sensitive areas such as children’s medicine and ophthalmic preparations. In addition, most active ingredients have good compatibility with Polyacrylic Acid and do not cause drug degradation or deactivation, which is essential for flexibility in formulation development.

Another competitive advantage of Polyacrylic Acid is that it is environmentally friendly. The water phase polymerization process adopted in the production process reduces the use of organic solvents and conforms to the principle of green chemistry. After waste, carbomer can be slowly decomposed into carbon dioxide and water through microbial action in the natural environment, without causing persistent pollution problems. With the increasingly stringent global environmental regulations, this degradable property has greatly improved its market competitiveness in daily chemical products.

From an economic point of view, the unit cost of Polyacrylic Acid is higher than that of some traditional thickeners, but its efficiency can bring about a reduction in the overall formula addition. For example, under normal conditions, the amount of viscosity required is usually only 1/5-1/3 of that of cellulosic products. This cost-effectiveness advantage is even more pronounced when the production scale is larger. In addition, Carbomer has very good batch stability and can control the viscosity of different batches of products to less than 5%, which helps companies reduce quality inspection and process adjustment costs.

Contact Us

Product Package picture:

Related References:

chemicalbook-Polyacrylic Acid

Polyacrylic Acid Manufacturer

Contact Us

As an experienced Polyacrylic Acid manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polyacrylic Acid CAS 9003-01-4 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.