Polyacrylamide CAS 9003-05-8

Polyacrylamide CAS 9003-05-8

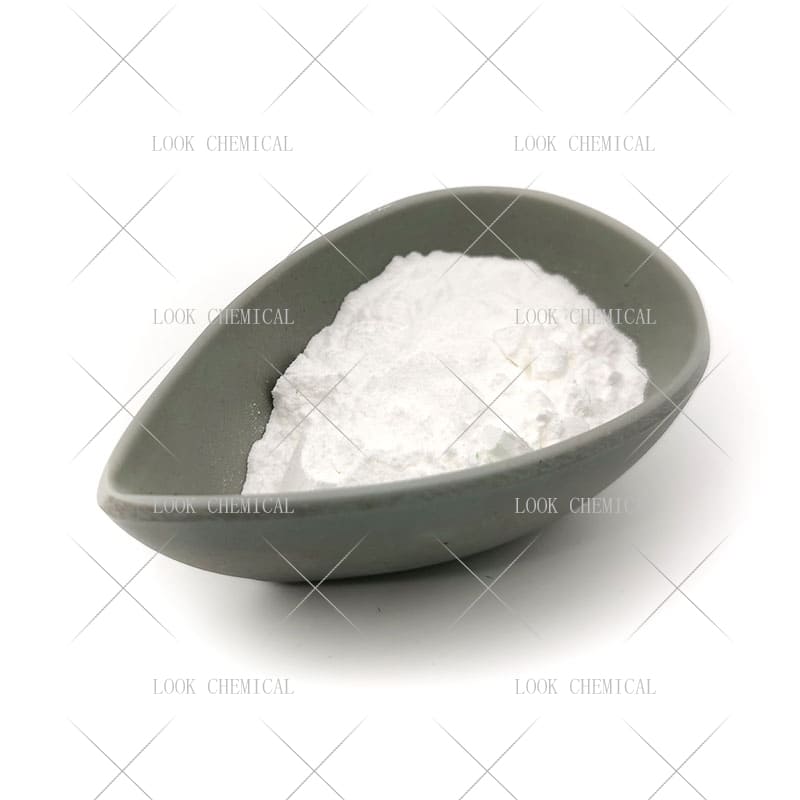

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polyacrylamide

CAS: 9003-05-8

MOQ: 1KG

Directory Guidance on Polyacrylamide

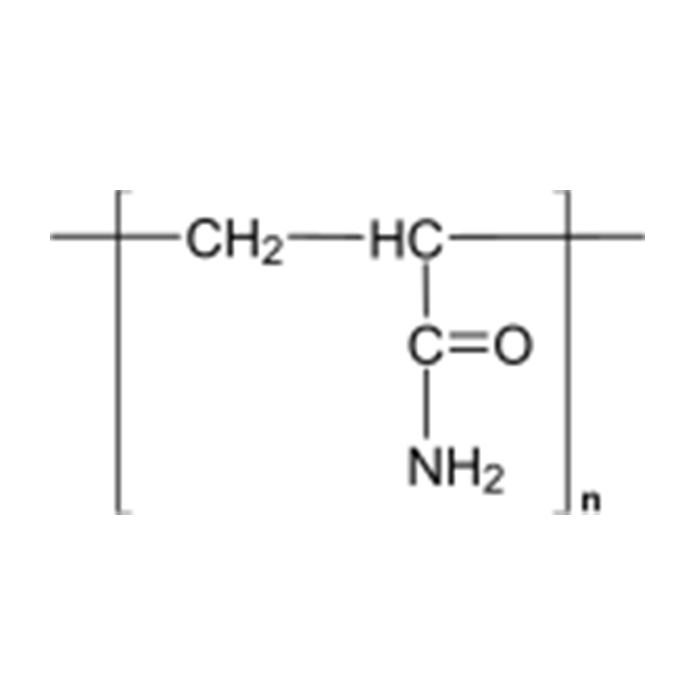

Chemical Structure

Basic Info:

| Melting point | >300 °C |

| density | 1.189 g/mL at 25 °C |

| Tg | 165°C |

| refractive index | n20/D 1.452 |

| Fp | >230 °F |

Product Introduction:

Polyacrylamide (PAM for short) is a linear polymer, which is formed by free radical-initiated polymerization of acrylamide (AM) monomer. It has good water solubility and high chemical activity and is one of the most widely used varieties of water-soluble polymers. Its molecular structural unit contains amide groups, which are easy to form hydrogen bonds and can be copolymerized with other monomers to obtain a variety of modified products. PAM can be divided into four types according to its ionic properties: non-ionic, anionic, cationic and amphoteric. It is insoluble in most organic solvents, but can be dissolved in water in any proportion. The aqueous solution is a uniform and transparent liquid.

Polyacrylamide appears as white powder or small particles, with a density of 1.302g/cm³ (23℃), a glass transition temperature of 153℃, and a softening temperature of 210℃. At a suitable low concentration, the PAM solution can be regarded as a mesh structure, with mechanical entanglement and hydrogen bonds between chains forming mesh nodes together; at a higher concentration, the solution is gel-like. PAM aqueous solution has good compatibility with many organic substances that are miscible with water, and also has good compatibility with electrolytes, and is insensitive to many substances.

The production steps of Polyacrylamide mainly include monomer production and polymerization reaction. The monomer production technology uses acrylonitrile as raw material, hydrates under the action of a catalyst to generate a crude product of acrylamide monomer, and obtains refined acrylamide monomer after refining. The polymerization reaction is to polymerize acrylamide monomer under the action of an initiator. With the development of technology, monomer technology has gone through three generations, from sulfuric acid catalytic hydration technology to skeleton copper catalytic production technology, and then to microbial nitrile hydratase catalytic production technology, continuously improving the conversion rate of acrylonitrile and the purity of the product.

The molecular weight of Polyacrylamide has little effect on solubility, but when the solution concentration is higher than 10%, high molecular weight polymers can present a gel-like structure due to the bonding of hydrogen atoms between molecules. High molecular weight solutions are pseudoplastic fluids with good rheological properties. It can be mostly ionized in water and belongs to a polymer electrolyte. It is divided into anionic, cationic and non-ionic types according to the characteristics of the dissociable groups.

Nature and Specifications:

| Item | Specification |

| Product Name | Polyacrylamide |

| CAS No. | 9003-05-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | 2-8°C |

| solubility | Water |

| form | Granules |

| color | White to faintly yellow |

| Odor | odorless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Polyacrylamide is an extremely efficient flocculant that can effectively remove suspended solids, colloidal particles, and other pollutants from water in the treatment industry. There are three varieties of Polyacrylamide with differing charged properties; anionic, cationic and nonionic are each suitable for treating different water quality conditions; thus helping increase mud concentration as well as improving quality in municipal wastewater treatment and industrial wastewater treatment environments.

Polyacrylamide is most often utilized in oil extraction as an oil displacement agent and thickener. In other words, this polymer can help improve oil recovery significantly while acting as a thickener for drilling fluids thereby increasing carrying rates and drilling efficiencies. Furthermore, its reduced interfacial tension facilitates improved discharge rates of crude oil during oilfield extraction, improving discharge. Furthermore, this same polymer may also be utilized as wastewater treatment treatment in order to remove pollutants from oilfield wastewater streams.

Polyacrylamide is also widely utilized in the mining industry. Used as a flocculant during mineral processing, Polyacrylamide acts to separate minerals and impurities from ore slurries while improving process efficiency. Furthermore, its use helps disperse and sedimentate particles such as metal mineral particle deposits in coal mines or ceramic deposits, saving resources while decreasing production costs.

Polyacrylamide is used in the paper industry as a thickener and retention agent to increase strength, leveling and runnability of paper products. It improves pulp dewatering ability and ensures a certain thickness and strength during manufacturing processes by controlling dewatering process. Polyacrylamide may also be used as filler fixative to increase tear strength, water resistance and surface smoothness for improved paper quality overall.

Polyacrylamide’s primary function in agriculture is soil improvement and water conservation, increasing soil water retention capacity while simultaneously decreasing water evaporation rates, improving air permeability and increasing soil permeability in dry or semi-arid environments. Furthermore, this technology can significantly decrease water loss or waste and increase efficiency by evenly penetrating into the ground surface for effective farmland irrigation systems.

Polyacrylamide is widely used for thickening and fixing dyes and finishing agents in textile production. It helps improve adhesion of dyes while preventing their loss through surface migration or penetration from within to fabric surface, prolonging and brightening color durability and brightness. Other uses for Polyacrylamide in textile finishing include increasing gloss, softness and wrinkle resistance while improving quality and comfort of fabrics.

Polyacrylamide can also be found in cosmetics and daily chemical products as a thickener, emulsifier and suspending agent, helping adjust product consistency while remaining stable during use. Common examples include skin creams, hair sprays and shampoos – Polyacrylamide helps enhance texture and effect when it comes to daily chemical products!

First, one of the most attractive advantages of polyacrylamide is that it has a strong flocculation effect. It is very effective in removing suspended matter, colloidal particles and small pollutants from water and aggregates these particles into large clumps (called floc) by the action of electric charge. This property makes the compound a major raw material in the water treatment industry, especially in the treatment of industrial wastewater, sewage and mud, which can significantly improve the treatment effect.

Another important advantage is its good water solubility and thickening properties. It is soluble in water and immediately produces a high viscosity solution. Even if the concentration is very low, it will produce a significant thickening effect. Therefore, it is widely used as a thickener and stabilizer in mining oil fields, paper making, textile and other fields to improve the efficiency and effect of the process.

The flexible molecular structure of polyacrylamide is also one of its important advantages. In practical applications, both its molecular weight and charge can be changed to obtain polymers with different properties. For example, in water treatment, mining and other industries, the flocculation effect and rheological properties of polyacrylamide can be adjusted to meet different industrial requirements by adjusting its charge density and molecular weight.

Polyacrylamide also has a good protective effect on the environment. In the water treatment process, polyacrylamide can effectively remove harmful substances as well as pollutants and suspended particles in the water, thereby reducing the impact of pollutants on the water environment. Compared to many other traditional chemicals used in water treatment, polyacrylamide residues are small and have little impact on water quality and the ecological environment. It has good degradability and low toxicity, and meets the requirements of modern environmental protection.

With polyacrylamide, production efficiency can be increased several times and even cost can be reduced. When used as thickening agent and oil displacement agent, it can improve oil recovery rate, reduce oil-water interfacial tension, and thus increase production. At the same time, the wastewater treatment, paper, mining and other industries have also witnessed the accelerated settlement of this compound, thereby improving the separation effect and reducing the processing time and cost.

In addition, polyacrylamide has good compatibility and can maintain stable performance under pH, salinity and temperature changes. Therefore, it can still perform well in some special environments. Such as high salinity, large pH fluctuations in wastewater treatment and mineral processing in mining. It’s very adaptable.

Contact Us

Product Package picture:

Related References:

chemicalbook-Polyacrylamide

Polyacrylamide Manufacturer

Contact Us

As an experienced Polyacrylamide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polyacrylamide CAS 9003-05-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.