Methyltriacetoxysilane CAS 4253-34-3

High Quality Methyltriacetoxysilane CAS 4253-34-3

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Methyltriacetoxysilane

CAS: 4253-34-3

MOQ: 1KG

Directory Guidance on Methyltriacetoxysilane

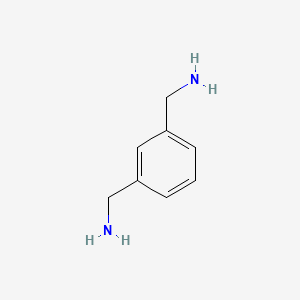

Chemical Structure

Basic Info:

| Melting point | 40-45 °C(lit.) |

| Boiling point | 94-95 °C9 mm Hg(lit.) |

| density | 1.20 g/mL at 20 °C(lit.) |

| vapor pressure | 0.053-26Pa at 20-25℃ |

| refractive index | 1.52-1.522 |

| Fp | 185 °F |

| solubility | soluble in Methanol |

Product Introduction:

Methyltriacetoxysilane (MTA or MTAS for short) is an organosilicon compound with numerous unique properties and applications. Its molecular formula is C7H12O6Si, its molecular weight 220.25, and it typically appears as a colorless to light yellow transparent liquid with an intense acetic acid smell, with an approximate density at 20 degC of 1.14-1.20g/cm3. Melting point lies between 40-45degC and boiling point at 110-112degC/17mmHg. It has good solubility within water but requires special moisture control measures when applied – therefore special care must be given in its application in terms of both moisture control as well as temperature management when applying MTA.

Chemically speaking, Methyltriacetoxysilane displays excellent thermal and weather stability at room temperature as well as resistance against decomposition. Thanks to the introduction of acetoxy groups, MTA also features excellent resistance against UV rays, friction penetration acid/alkali substances as well as UV radiation which allows it to successfully inhibit or postpone oxidation reactions from occurring or worsening over time. Furthermore, its electrical properties make MTA suitable for use as electrical insulation materials and electrolyte materials further expanding its potential application possibilities in this field.

Methyltriacetoxysilane has proven invaluable in the production of silicone polymers, particularly as a crosslinking agent in room temperature vulcanized silicone rubber. Reacting with water, it generates silicon dioxide and acetic acid to crosslink silane compounds and improve their water resistance properties; additionally it is widely employed in producing waterproofing agents, silicone rubber, silane-modified materials, silane curing agents etc. and finds application across many fields such as construction, automobiles, textiles paints & chemicals etc.

Pay particular attention when storing and using Methyltriacetoxysilane, taking particular note of safety issues when doing so. The substance should be stored in a cool, dry location that provides ample ventilation; moisture exposure should be prevented by keeping away from sources like fire and heat; additionally it is flammable to some extent, so when handling make sure appropriate protective clothing and gloves are worn to avoid direct skin and eye contact in order to ensure safe operation.

Methyltriacetoxysilane has become a cornerstone of silicone chemistry due to its excellent chemical and physical properties, such as its role in cross-linking and surface treatment. Technology advancement has expanded its applications in many fields; however, when used it must take precautionary measures against fire prevention and waterproofing to avoid possible accidents during its application.

Nature and Specifications:

| Item | Specification |

| Product Name | Methyltriacetoxysilane |

| CAS No. | 4253-34-3 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | solid |

| color | White or Colorless to Almost white or Almost colorless |

| Specific Gravity | 1.175 |

| Water Solubility | 1000g/L at 20℃ |

| Sensitive | Moisture Sensitive |

| Hydrolytic Sensitivity | 7: reacts slowly with moisture/water |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

1.Methyltriacetoxysilane (MTA) is widely used as a cross-linking agent in adhesives and sealants manufactured using silicone-based technologies, specifically adhesives containing hydroxyl groups, to form strong yet elastic chemical bonds between these hydroxyl groups and adhesive molecules that significantly increase bond strength, cohesion and speed of curing process compared with products without MTA additive. Furthermore, MTA also plays an essential role in moisture environments; permitting adhesives and sealants to maintain excellent performance even under humid conditions.

2. Paint Industry

Within the coatings industry, Methyltriacetoxysilane (MTA) is increasingly being added to coatings in order to increase water resistance, scratch resistance and adhesion with various substrates. Furthermore, adding MTA can also increase UV stability and chemical resistance of coatings thereby reducing cracking, fading or discoloration due to UV radiation, temperature variations or moisture, thus prolonging their service life in outdoor exposure environments.

3. Plastic Industry

Methyltriacetoxysilane plays a pivotal role as a coupling agent in the production of thermoplastic and thermoset plastics, substantially improving their mechanical properties such as tensile strength, flexural strength and impact resistance by improving compatibility between plastics and inorganic fillers (such as glass fiber or mineral powder). Furthermore, MTA improves processing properties while increasing strength and durability of composite materials, which makes it widely utilized in high strength plastic product manufacture, automotive parts assembly as well as electronic casings among others fields.

4. Electronics Industry

Methyltriacetoxysilane (MTA) is widely utilized within the electronics industry as a surface modifier to improve adhesion of electronic components to printed circuit boards (PCBs) and other substrates, including PCBs themselves. By reacting with these surfaces, MTA can increase surface activity and enhance adhesion rates to ensure long-term use without components falling off or malfunctioning over time. Furthermore, MTA serves as an antimicrobial coating protecting electronic equipment against moisture, chemicals and harsh environmental conditions, protecting components against corrosion aging or other issues related to long-term usage over time.

5. Textile Industry

In the textile industry, Methyltriacetoxysilane (MTA) is often employed as an effective waterproofing treatment, significantly increasing water resistance and stain resistance of textiles. MTA reacts with the hydroxyl groups on fiber surfaces to form a highly hydrophobic protective film which makes textiles watertight, oil-proof and anti-fouling. MTA can be found in outdoor clothing, sportswear, tents and similar products, while it is also widely utilized as cross-linking agents which improve durability while improving washability, washability aging resistance over long term usage – perfect for production environments that experience frequent washes or frequent washings!

6. Production of Silicone Resin

Methyltriacetoxysilane (MTA), one of the intermediates of methylsilanetriol, plays an essential role in producing silicone resins. Reacting with other organosilicon compounds, MTA can create resins with superior thermal stability, weather resistance and electrical insulation properties for use in coatings, adhesives, plastics and sealants, making them suitable for aerospace, automotive, construction and other industries requiring high performance materials.

7. Additional Applications

Methyltriacetoxysilane also proves its worth in many other fields.

Surface Modification of Microparticles and Nanoparticles: Methyltriacetoxysilane can be used to modify the interfaces between inorganic fillers (such as silicate, bauxite and iron oxide ) and organic substrates, improving compatibility and thus the performance of composite materials.

Sol-gel application: Sol-gel is an innovative coating application method which utilizes hydrolyzed Methyltriacetoxysilane hydrolysate products as crosslinkers with other ingredients to form antifouling coatings with excellent UV stability, making them suitable for optical, electronic equipment and architectural coating applications.

Gas chromatography/liquid chromatography stationary phase treatment agent: Methyltriacetoxysilane can be used to strengthen and extend the durability and separation performance of chromatography columns by treating their stationary phase with this chemical solution.

1. Accelerate Cross-Linking Reaction

Methyltriacetoxysilane can significantly accelerate cross-linking reactions when used as an agent in materials like silicone rubber, adhesives and sealants. By reacting with water or moisture to produce acetic acid (CH3COOH) and silica (SiO2) acetic acid is produced, which promotes cross-linking reaction of silicone rubber by improving hardness, elasticity and heat resistance of materials such as rubber. Compared with other traditional cross-linking agents MTA can cure quickly under normal and humid conditions.

2. Water Sensitivity and Self-Curing

Methyltriacetoxysilane has excellent water sensitivity, gradually hydrolyzing into acetic acid in response to moisture or humidity in the air, thus making it self-curing at room temperature and making it an excellent material for producing deacidified RTV silicone rubber (RTV silicone rubber). Furthermore, MTA’s exceptional performance under humid environments means that even though its composition changes, MTA still plays an invaluable role.

3. Enhancing Weather Resistance and High Temperature Resistance

Products cross-linked by Methyltriacetoxysilane, particularly silicone rubber, exhibit remarkable weather resistance and high temperature resistance. Cross-linking reactions enhanced with MTA help the thermal stability of silicone rubber to avoid physical deformation or failure at high temperatures; consequently MTA is widely utilized in applications requiring high temperature resistance, UV resistance, or aging resistance like building sealing, automotive parts protection or electronic equipment protection.

4. Increase Adhesion and Structural Strength

As a coupling agent, Methyltriacetoxysilane can strengthen adhesion between silicone-based materials such as silicone rubbers and other substrates such as glass, metal or plastic substrates (for instance). Furthermore, MTA significantly enhances mechanical properties and structural strength by increasing surface activity of silicon-based materials and increasing compatibility with other inorganic or organic materials; hence it is often employed in the production of modified adhesives, coatings or textiles etc.

5. Low Toxicity and Environmental Protection Methyltriacetoxysilane stands out as an environmentally friendly cross-linking agent because its reaction products primarily consist of silica and acetic acid – less toxic and volatile substances than some of the alternatives; making it safer and more eco-friendly than competing cross-linking agents for use in areas like medical devices or food packaging, where toxic fumes might otherwise escape into the atmosphere. Utilizing MTA helps limit harmful substance releases while meeting modern safety and environmental protection standards.

6. Wide Applicability

Methyltriacetoxysilane can be applied in a wide variety of fields beyond cross-linking silicone rubber, including adhesives, sealants, coatings, plastics and textile finishing. Due to its adaptability to different environments and materials, MTA can find its place across numerous industries.

7. Cost-Effectiveness

Methyltriacetoxysilane generally offers more cost-effectiveness compared to other cross-linkers and silane compounds, and in actual production can improve product performance while simultaneously decreasing production costs by shortening curing times and improving production efficiencies.

8. Enhance Product Stability

The silica (SiO2) produced from cross-linking with Methyltriacetoxysilane helps ensure long-term product stability. The cross-linked network of silicene chains improves anti-aging, UV blocking, and anti-oxidation properties of material allowing it to maintain good mechanical properties and appearance in harsh environments.

Contact Us

Product Package picture:

Related References:

chemicalbook-Methyltriacetoxysilane

Pubchem-Methyltriacetoxysilane

Methyltriacetoxysilane Manufacturer

Contact Us

As an experienced Methyltriacetoxysilane manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Methyltriacetoxysilane CAS 4253-34-3 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.