Methyl Lactate CAS 547-64-8

Factory wholesale Methyl Lactate CAS 547-64-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Methyl Lactate

CAS: 547-64-8

MOQ: 1KG

Directory Guidance on Methyl Lactate

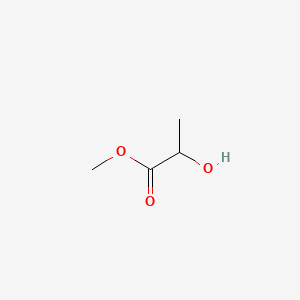

Chemical Structure

Basic Info:

| Melting point | -66°C |

| alpha | [α]D20+1.410~+1.418 |

| Boiling point | 35 °C (6 mmHg) |

| density | 1.093 g/mL at 20 °C(lit.) |

| refractive index | n20/D 1.413 |

| Fp | 49 °C |

Product Introduction:

Methyl Lactate (MLA for short) is an organic compound created through an esterification reaction between lactic acid and methanol, with its chemical formula being C4H8O3. As a colorless and transparent liquid with an approximate boiling point of 144degC and miscibility with water, this organic compound features low toxicity and biodegradability while being miscible with biodiesel fuels. Methyl Lactate’s molecular structure features both lactic acid (a-hydroxypropionic acid) as well as methoxy group properties that give this organic compound unique chemical reactivity such as dehydration, transesterification and oxidation capabilities – making it key platform compound in biorefineries for biomass conversion applications.

Traditional methods for producing Methyl Lactate include chemical catalysis with homogeneous acid catalysts like sulfuric acid or enzyme catalysis; however, these methods have numerous disadvantages such as difficult catalyst recovery and by-product formation. Tin silicon molecular sieves (such as Sn-MFI and Snb) have long been used as one-pot catalytic converters of biomass sugars such as glucose and fructose into methyl lactate via isomerization or retro-aldol condensation pathways, directly producing it through isomerization or retro-aldol condensation pathways. Not only does this type of catalyst eliminate fluoride ions used in traditional processes; its multi-level pore structure design optimizes mass transfer efficiency further improving both yield and selectivity significantly.

From a thermodynamic perspective, the production of methyl lactate typically involves high temperature (180-220degC) and pressure conditions, with methanol serving as the solvent; reaction times generally being set between 6-12 hours. Studies have demonstrated the significance of acid sites (like Lewis acid) as critical elements in controlling reaction pathways. Low Bronsted acid (B acid) content can prevent side reactions (such as dehydration of sugars to produce furfural), while high Lewis acid density promotes the conversion of intermediates directional.

Methyl Lactate’s raw material source relies heavily on biomass resources such as glucose and xylose produced from hydrolysis of cellulose and hemicellulose, in contrast to petroleum-based chemicals and fulfilling circular economy requirements. Thanks to advances in catalytic technology, the yield has skyrocketed from less than 40% when catalysis was first developed to over 53.6% today; some advanced processes even achieve 87.4% selective conversion of methyl acrylate, making this an excellent candidate for large scale applications.

Nature and Specifications:

| Item | Specification |

| Product Name | Methyl Lactate |

| CAS No. | 547-64-8 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | Flammables area |

| pka | 13.07±0.20(Predicted) |

| form | Liquid |

| color | Clear colorless to pale yellow |

| Specific Gravity | 1.09 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Methyl Lactate is an important chemical industry solvent with numerous applications in coating production, paint and ink manufacturing, as a high-boiling point solvent with excellent performance that can dissolve various resins and polymers, such as cellulose nitrate and acetate, making it popular with coating producers, paint companies and ink printers alike. Methyl Lactate’s fast drying speed, good film-forming properties and high gloss properties enable faster performance as a coating solvent and an advantaged user experience overall performance and use effect in production processes as well as textile printing and dyeing industries alike.

Methyl Lactate plays an integral part of the food industry. As an additive it can serve as both a flavoring agent and spice carrier to give food its distinctive flavor, while its solubility and safety allow extracting natural flavors from herbs and spices for food additives with natural flavor profiles. Furthermore, in terms of packaging materials it plays an integral part in producing biodegradable polylactic acid plastics which not only possess good mechanical properties, but can be broken down by nature to reduce pollution in our environments.

Methyl Lactate can serve many roles within medicine. It can serve as both a solvent and excipient in the pharmaceutical process to produce topical creams, ointments, injections and other dosage forms to better disperse and absorb drugs; and also serve as a preservative in pharmaceutical products to extend shelf life of drugs. Furthermore, its chiral properties play an integral part in synthesizing chiral drugs; Methyl Lactate can synthesize specific single isomer drugs with specific biological activities for improved efficacy and safety of drugs.

Methyl Lactate can be used as a raw material in agriculture to synthesize chiral pesticides through stereospecific synthesis, producing single R isomers such as metalaxyl-M and quizalofop-p-ethyl pesticides through stereospecific synthesis. When compared with traditional racemic pesticides, these chiral versions boast higher biological activity with reduced dosage requirements; thus reducing pollution of pesticides into the environment as well as nontarget organism impacts while meeting modern green agriculture development requirements.

Technically speaking, Methyl Lactate production has achieved an exceptional degree of environmental friendliness. The use of heterogeneous catalysts reduces wastewater discharge while designing multi-level pore molecular sieves (such as intercrystalline mesoporous structures) improves reaction efficiency further – for instance Sn-MFI molecular sieves with mesoporous channels accelerate diffusion while inhibiting side reactions to increase yield by more than 20% and regeneration performance (Cs-beta zeolite activity recovery rate after calcination is 86%), further cutting costs significantly.

Methyl Lactate’s high purity (>99%) and chemical stability make it ideal for high-end applications, such as solvent use in work environments with reduced risk of vapor exposure; additionally, its reaction path is well defined with controllable by-products; which makes it particularly suited for pharmaceutical and electronic chemical manufacturing processes.

Economic efficiency is another significant competitive advantage of Methyl Lactate. Due to advances in biomass conversion technology, its production costs have come closer than ever to those associated with petroleum-based solvents. With fructose as the raw material being converted, single pass MLA yield exceeds 50% and reuse of catalyst is over five times reducing fixed investment significantly; as well as policy support (such as carbon tax incentives or subsidies for bio-based products). All these features make Methyl Lactate even more market-attractive!

Methyl Lactate’s industrial chain cannot be underestimated when considering its synergistic effects. For instance, its downstream products (PLA and acrylates) are highly compatible with emerging industries like new energy vehicles and degradable packaging forming an end-to-end cycle from raw materials to end products thereby increasing resource utilization efficiency while creating opportunities for cross-industry cooperation among enterprises.

Contact Us

Product Package picture:

Related References:

chemicalbook-Methyl Lactate

Methyl Lactate Manufacturer

Contact Us

As an experienced Methyl Lactate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Methyl Lactate CAS 547-64-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.