Methyl Acetate CAS 79-20-9

Factory wholesale Methyl Acetate CAS 79-20-9

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Methyl Acetate

CAS: 79-20-9

MOQ: 1KG

Directory Guidance on Methyl Acetate

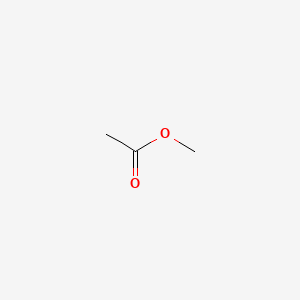

Chemical Structure

Basic Info:

| Melting Point | -98 °C (lit.) |

| Boiling Point | 57-58 °C (lit.) |

| Density | 0.934 g/mL at 25 °C |

| Vapor Density | 2.55 (vs air) |

| Vapor Pressure | 165 mm Hg ( 20 °C) |

| Refractive Index | n20/D 1.361(lit.) |

Methyl Acetate Introduction:

Methyl Acetate (chemical formula C₃H₆O₂) is a colorless, transparent, volatile liquid compound with a special fruity aroma. Its molecular structure is composed of methyl and acetoxy groups connected by ester bonds. As a product of the esterification reaction of acetic acid and methanol, Methyl Acetate has a boiling point of about 57°C and a density of 0.93 g/cm³. It is easily soluble in most organic solvents, but has a low solubility in water. This low boiling point and high volatility give it unique advantages in industrial applications.

From a chemical property point of view, the ester structure of Methyl Acetate gives it good reactivity and can participate in a variety of chemical reactions such as hydrolysis and transesterification, which lays the foundation for its wide use in chemical synthesis.

Its preparation process is mainly achieved through esterification reaction catalyzed by concentrated sulfuric acid. In recent years, with the promotion of the concept of green chemistry, the application of solid acid catalysts and continuous flow reactors has significantly improved the synthesis efficiency and reduced the problem of waste acid emissions. To maintain purity during storage and transport, Methyl Acetate should be stored in dark sealed environments free from strong oxidants or high temperature environments so as to minimize decomposition or combustion risks.

In terms of physical properties, the polarity of Methyl Acetate is moderate, and its solubility parameter (HSP) is approximately 18.3 MPa¹/². This value enables it to exhibit good solubility for both polar and non-polar substances. This broad-spectrum solubility gives it a high degree of flexibility when formulating mixed solvents.

The surface tension of Methyl Acetate is relatively low (approximately 25 mN/m), which is conducive to the formation of a uniform liquid film during the spraying process and enhances the gloss and adhesion of the coating. In terms of thermodynamic properties, its latent heat of evaporation is 367 kJ/kg, significantly lower than that of similar solvents such as ethyl acetate (426 kJ/kg). This means that it has a faster drying speed at the same temperature, which is of great significance for improving industrial production efficiency.

Nature and Specifications:

| Item | Specification |

| Product Name | Methyl Acetate |

| CAS No. | 79-20-9 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| Fp | 3.2 °F |

| Storage Temp. | no restrictions. |

| Solubility | 250g/l |

| Form | Solution |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Methyl Acetate

In the field of solvents, Methyl Acetate has become an important component in the coating and ink industries. Its rapid evaporation characteristic makes it particularly suitable for spraying processes that require short drying cycles, such as automotive refinish paints and wood coatings. In ink manufacturing, the synergistic effect of Methyl Acetate and alcohol solvents can effectively regulate viscosity and improve printability.

Compared with traditional ketone solvents, it has a weaker residual odor and a smaller swelling effect on plastic substrates. Therefore, it has gradually replaced part of the market share of acetone and cyclohexanone in the packaging and printing field. It is worth noting that in the field of cleaning agents in the electronics industry, high-purity Methyl Acetate is used in the precision cleaning processes of liquid crystal panels and semiconductor components due to its characteristic of low metal ion residue.

In the field of pharmaceutical intermediate synthesis, Methyl Acetate is often used as an acetylation reagent to participate in the modification of drug molecular structures, such as the synthesis of side chains of cephalosporin antibiotics. Furthermore, in the polyurethane industrial chain, Methyl Acetate can be used as a raw material for carbonylation reactions to participate in the preparation of isocyanates. This technological route has higher safety and environmental friendliness compared with the traditional phosgene method.

In the field of new energy materials, the application of Methyl Acetate is expanding rapidly. In the electrolyte system of lithium-ion batteries, as a co-solvent, it can effectively improve the conductivity and low-temperature performance of the electrolyte. In the preparation process of proton exchange membranes for fuel cells, Methyl Acetate is used in the uniform coating process of membrane materials due to its good solubility for perfluorosulfonic acid resin.

From the perspective of environmental governance, Methyl Acetate demonstrates unique value in the field of waste gas treatment. Its high volatility feature is applied in the concentration and recovery process of volatile organic compounds (VOCs), and the effective treatment of industrial waste gas can be achieved through the combined condension-adsorption technology. In terms of soil remediation, Methyl Acetate, as a mild extractant, can selectively dissolve organic pollutants in the soil without damaging the soil structure. This characteristic makes it have application potential in the remediation projects of sites contaminated by organochlorine pesticides.

The Advantages Of Methyl Acetate

In terms of solubility, Methyl Acetate exhibits a unique balance. Its ability to dissolve resins is comparable to that of ethyl acetate, but its volatilization rate is faster; compared with acetone, although its initial solubility is slightly lower, its swelling effect on polar polymer materials is more controllable.

In terms of environmental performance, the outstanding advantage of Methyl Acetate is its biodegradability. According to the OECD 301B standard test, its 28-day biodegradability can reach more than 85%, which is much higher than the less than 10% of traditional halogenated solvents.

In the storage and transportation links, Methyl Acetate has significant stability advantages. Its flash point is -10°C. Although it is a flammable liquid, its transportation risk is more controllable than that of low-flash point solvents such as ether (-45°C). It is not easy to self-polymerize or decompose under normal storage conditions, and the shelf life can reach more than 24 months. Its vapor density is 2.6 (air = 1), and it is easy to diffuse at low places when leaking. With the appropriate ventilation system, the concentration of the working environment can be effectively controlled.

From the perspective of the economic efficiency of the production process, the raw materials of Methyl Acetate, methanol and acetic acid, are both bulk chemical products with stable supply and small price fluctuations. Modern continuous production processes enable a single unit to have an annual production capacity of 100,000 tons, and the unit energy consumption is about 40% lower than that of traditional intermittent processes. In terms of by-product utilization, the trace water produced during the production process can be recovered by molecular sieve adsorption, and the reaction mother liquor can be used as industrial fuel after distillation, realizing efficient resource circulation. These technological innovations have reduced the comprehensive production cost of Methyl Acetate by about 28% compared with ten years ago, providing strong support for its market competitiveness.

With the acceleration of the green transformation of the global chemical industry, the market prospects of Methyl Acetate continue to improve. Its positioning as an environmentally friendly solvent not only meets the sustainable development requirements of the EU Green Deal, but also meets the emission reduction goals of China’s “dual carbon” strategy. Driven by technological innovation, high-purity electronic-grade products, bio-based Methyl Acetate and other sub-sectors are expected to form new growth poles in the future.

From the toxicological data, the median lethal dose (LD50) of Methyl Acetate is 3700 mg/kg (rat oral), which is a practically non-toxic level, and the workplace exposure limit (TLV) is 200 ppm, which is significantly safer than benzene solvents. These characteristics make it easier for it to pass the review of environmental protection regulations in various countries, especially under the framework of the EU REACH regulations and the North American TSCA Act, it has stronger market access advantages.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Methyl Acetate

Methyl Acetate Manufacturer

Contact Us

As an experienced Methyl Acetate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Methyl Acetate CAS 79-20-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.