Isopropyl Myristate CAS 110-27-0

Factory wholesale Isopropyl Myristate CAS 110-27-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Isopropyl Myristate

CAS: 110-27-0

MOQ: 1KG

Directory Guidance on Isopropyl Myristate

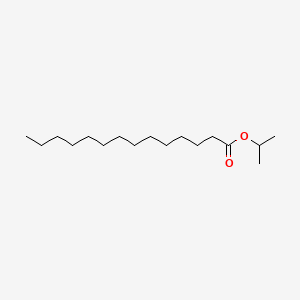

Chemical Structure

Basic Info:

| Melting point | ~3 °C (lit.) |

| Boiling point | 193 °C/20 mmHg (lit.) |

| density | 0.85 g/mL at 25 °C (lit.) |

| vapor pressure | <1 hPa (20 °C) |

| FEMA | 3556 | ISOPROPYL MYRISTATE |

| refractive index | n20/D 1.434(lit.) |

Product Introduction:

Isopropyl Myristate (IPM for short) is an ester compound synthesized by esterification reaction of myristic acid and isopropyl alcohol. Its chemical structure is composed of tetradecanoic acid (C14) combined with the hydroxyl group of isopropyl alcohol, with a molecular formula of C17H34O2 and a molecular weight of 270.45. As a colorless to light yellow transparent oily liquid, it has extremely low viscosity and excellent spreadability, and is almost odorless. These physical properties make it popular in many industrial fields. From the perspective of chemical properties, Isopropyl Myristate has high chemical stability, is not easy to oxidize or hydrolyze, and is miscible with most organic solvents, but its solubility in water is extremely low, which lays the foundation for its application in hydrophobic systems.

In industrial production, Isopropyl Myristate is mainly prepared by ester exchange or direct esterification. The transesterification method usually uses methyl myristic acid and isopropanol as raw materials and reacts under the action of acidic or alkaline catalysts; the direct esterification method is generated by dehydration condensation of myristic acid and isopropanol under high temperature and catalyst conditions. Both methods require post-processing steps such as distillation, decolorization, and filtration to ensure the purity of the product. At present, the purity of high-purity Isopropyl Myristate (such as pharmaceutical grade or cosmetic grade) is usually required to reach more than 99%, and the residual free acid and alcohol content must be controlled at the ppm level to meet strict industry standards.

As a multifunctional synthetic ester, the physical and chemical properties of Isopropyl Myristate are closely related to its molecular structure. Its low freezing point (about -3°C) and high boiling point (about 167°C/20mmHg) keep it liquid over a wide temperature range, while its flash point (about 110°C) gives it good processing safety. It is worth noting that the surface tension of this substance at room temperature is only 28-30 mN/m, which enables it to significantly reduce the viscosity of the oil phase system while improving its compatibility with other ingredients. In addition, its refractive index (1.434-1.438) is close to that of most oils and fats, which makes it less likely to produce optical differences in mixed systems.

From the current development status of the industry, the market demand for Isopropyl Myristate is showing a steady growth trend. According to the global chemical market analysis report, the annual compound growth rate of this product is expected to reach 4.2% between 2020 and 2025, mainly driven by technological innovations in the fields of cosmetics, pharmaceuticals and industrial lubrication. At present, the world’s major manufacturers are concentrated in Europe, the United States and the Asia-Pacific region, among which BASF of Germany, Sigma-Aldrich of the United States and NOF of Japan occupy a leading position in technology. With the popularization of the concept of green chemistry, the research and development process of preparing Isopropyl Myristate from bio-based raw materials is accelerating, which is expected to further expand its application boundaries.

Nature and Specifications:

| Item | Specification |

| Product Name | Isopropyl Myristate |

| CAS No. | 110-27-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | >230 °F |

| storage temp. | 2-8°C |

| solubility | <0.05mg/l |

| form | Liquid |

| color | Clear |

| Specific Gravity | 0.855 (20/4℃) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the cosmetics field, Isopropyl Myristate has become an important choice for formulators due to its unique properties. As a lightweight synthetic ester, it can effectively adjust the skin feel of the formula, reduce the greasy feeling in sunscreen and foundation, and enhance the ductility and skin-fitting of the product. The long-chain alkyl group in its molecular structure gives it good sealing properties, which can be used as a moisturizer to assist the stratum corneum in retaining moisture, and in the emulsified system, it can be used as a co-solvent to improve the solubility of active ingredients. It is worth noting that Isopropyl Myristate shows excellent compatibility with both silicone oil and mineral oil, which makes it widely used in water-in-oil, oil-in-water and anhydrous formulation systems.

The application of Isopropyl Myristate in the pharmaceutical industry is mainly concentrated in transdermal drug delivery systems and topical preparations. As a percutaneous absorption enhancer, it can reversibly change the arrangement of stratum corneum lipids and increase the penetration rate of drug molecules. This mechanism is particularly important in hormone patches and analgesic ointments. In the ointment matrix, it can not only adjust the consistency to prevent the ointment from hardening, but also act as a drug crystallization inhibitor to maintain the stability of the preparation. Recent studies have found that Isopropyl Myristate has a solubilizing effect on some poorly soluble APIs (active pharmaceutical ingredients), which provides more possibilities for the development of new drug delivery systems.

The application in the industrial field highlights the versatility of Isopropyl Myristate. In metalworking fluids, it can effectively reduce tool wear as an extreme pressure additive; in the plastics industry, its low volatility and high migration stability make it an ideal plasticizer for polymers such as PVC; in precision instrument lubrication, its low residual characteristics can avoid the pollution problems caused by traditional oils and fats. In addition, in special inks and coatings, it can improve surface finish as a leveling agent without affecting the drying speed of the system.

From the perspective of market application trends, Isopropyl Myristate is penetrating into high value-added fields. In the electronics industry, its dielectric constant (about 3.2) and volume resistivity (>1×10^14 Ω·cm) make it a candidate material for high-end insulating oils; in the new energy field, it is exploring its feasibility as an additive for lithium-ion battery electrolytes. As regulations tighten restrictions on traditional plasticizers, research on the application of this substance in food contact materials is also gradually advancing. It is worth noting that the development of nanotechnology has opened up new directions for it, such as as a surface modifier for nanoparticles or a stabilizer for drug carriers.

From the perspective of product performance advantages, the core competitiveness of Isopropyl Myristate lies in its excellent compatibility and safety. Compared with natural oils, its molecular structure is clear and its batch stability is excellent, which can ensure the repeatability of industrial production. Compared with similar synthetic esters (such as isopropyl palmitate), its carbon chain length makes it have both moderate polarity and non-polarity. This balance makes it more applicable in complex formulations. Toxicological data show that its acute oral toxicity (LD50>5000 mg/kg) and skin irritation (rabbit experiments show no irritation) meet international standards, which provides a fundamental guarantee for its application in personal care products.

In terms of stability, Isopropyl Myristate shows antioxidant capacity that exceeds most esters. Accelerated aging experiments show that its acid value does not increase by more than 0.2 mg KOH/g after storage for 6 months at 40°C/75%RH, and the peroxide value remains at an undetectable level. This chemical inertness not only extends the shelf life of the end product, but also reduces the amount of antioxidants added in the formula. In addition, its thermal stability (thermal decomposition temperature>250°C) enables it to withstand harsh process conditions such as high-temperature sterilization, which is of key value in the production of sterile preparations.

The economic advantage should not be ignored. Although the unit mass cost of Isopropyl Myristate is higher than that of mineral oil, its low addition amount (usually 0.5-5%) can significantly improve the performance of the system, making the comprehensive use cost competitive. Taking cosmetic emulsion as an example, adding 3% Isopropyl Myristate can reduce the amount of emulsifier by 15-20% and enhance the sensory experience. From the perspective of the supply chain, its liquid state at room temperature reduces the difficulty of storage and transportation, and the wide range of raw material sources (palm oil and coconut oil can derive myristic acid) ensures the stability of supply.

Environmental protection is another outstanding advantage of Isopropyl Myristate. Biodegradation experiments have confirmed that its degradation rate of the OECD 301B standard within 28 days exceeds 85%, which is much higher than most synthetic esters. The atomic utilization rate of the esterification reaction in the production process can reach more than 92%, which is in line with the principles of green chemistry. As the global demand for sustainable chemicals grows, this material with both high performance and environmental protection characteristics is gaining more policy support and technical attention.

The potential for technological innovation constitutes the long-term competitive advantage of Isopropyl Myristate. Advances in molecular modification technology have led to the development of a series of functionalized products. For example, IPM derivatives with hydroxyl groups can enhance polarity, while fluorination modification can give it super-hydrophobic properties. In terms of synthetic processes, the application of enzyme catalysis technology transforms the reaction conditions from traditional high temperature and high pressure to a mild environment, significantly reducing energy consumption. These technological evolutions not only improve product performance, but also provide technical support for its development of high-end application markets.

Contact Us

Product Package picture:

Related References:

chemicalbook-Isopropyl Myristate

Isopropyl Myristate Manufacturer

Contact Us

As an experienced Isopropyl Myristate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Isopropyl Myristate CAS 110-27-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.