Hydroxyethyl Methacrylate CAS 868-77-9

High Quality Hydroxyethyl Methacrylate CAS 868-77-9

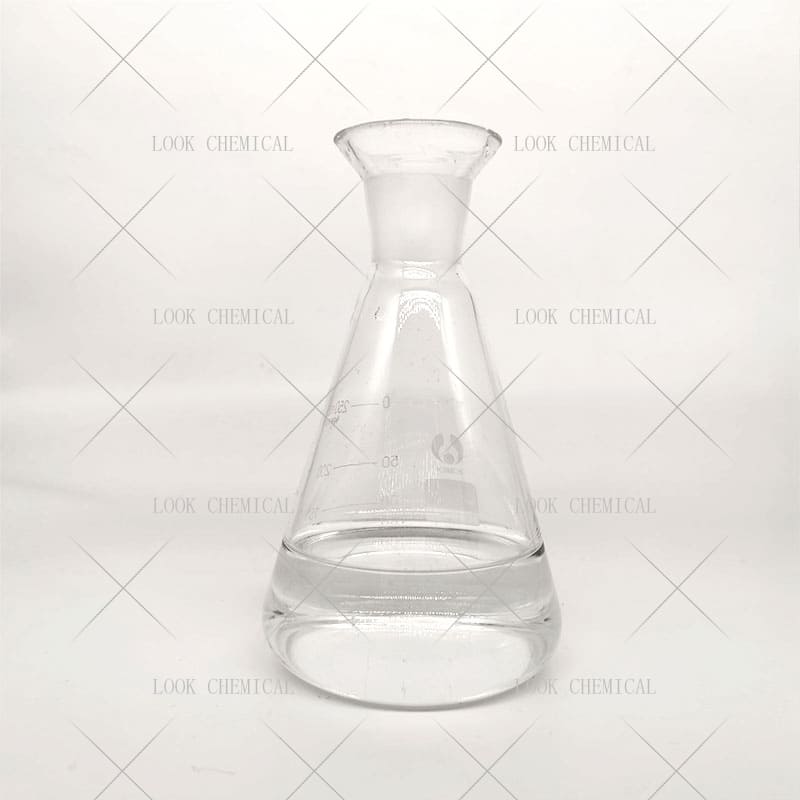

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Hydroxyethyl Methacrylate

CAS: 868-77-9

MOQ: 1KG

Directory Guidance on Hydroxyethyl Methacrylate

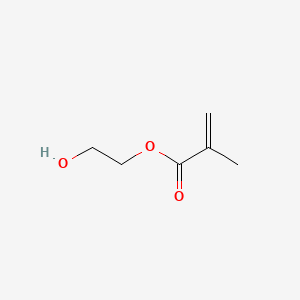

Chemical Structure

Basic Info:

| Melting point | -12 °C |

| Boiling point | 67 °C3.5 mm Hg(lit.) |

| density | 1.073 g/mL at 25 °C(lit.) |

| vapor density | 5 (vs air) |

| vapor pressure | 0.01 mm Hg ( 25 °C) |

| refractive index | n20/D 1.453(lit.) |

Product Introduction:

Hydroxyethyl Methacrylate is a bifunctional organic monomer that contains both vinyl and hydroxyl functional groups in its chemical structure.The synthesis of Hydroxyethyl Methacrylate is mainly achieved through the esterification reaction of ethylene oxide (EO) and methacrylic acid (MAA). The process technology threshold is relatively high, especially the production of high-purity products has strict requirements on catalysts, reaction conditions and post-processing processes. Its physical properties are colorless and transparent liquids with a boiling point of about 95°C, a density of 1.074 g/cm³, and a flash point of 108°C. It is easy to flow and miscible with water at room temperature, but it needs to be stored at low temperature (<10°C) and in the presence of inhibitors to prevent self-polymerization.

From the perspective of chemical stability, Hydroxyethyl Methacrylate is sensitive to light and heat, and is prone to free radical polymerization under ultraviolet or high temperature conditions. This feature is both its application advantage and increases the challenges of storage and transportation. To inhibit self-polymerization, industrial products usually add 200±50 ppm of MEHQ inhibitor and use inert gas protection packaging. In terms of toxicity, Hydroxyethyl Methacrylate is a low-toxic substance. Rat experiments show that its inhalation toxicity is low, but direct contact should still be avoided. Protective equipment should be worn during operation and ventilation should be ensured.

The global Hydroxyethyl Methacrylate production pattern shows obvious regional concentration. Before 2020, high-end production capacity was mainly distributed in Japan, Germany and the United States, among which Mitsubishi Chemical of Japan occupied a dominant position, and most of its products were exported to emerging markets such as my country. In the early days, Chinese local enterprises mainly focused on low-end products (purity 95-96%), but in recent years, with the breakthrough of technical barriers by enterprises such as Wanhua Chemical, relying on self-developed processes and self-sufficiency of raw materials, they have achieved large-scale production of high-end Hydroxyethyl Methacrylate (purity ≥98%), significantly reducing dependence on imports.

Nature and Specifications:

| Item | Specification |

| Product Name | Hydroxyethyl Methacrylate |

| CAS No. | 868-77-9 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 207 °F |

| storage temp. | 2-8°C |

| solubility | Chloroform, Methanol (Slightly) |

| pka | 13.83±0.10(Predicted) |

| form | Liquid |

| color | Clear |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Hydroxyethyl Methacrylate is a bifunctional organic monomer that contains both vinyl and hydroxyl functional groups in its chemical structure.The synthesis of Hydroxyethyl Methacrylate is mainly achieved through the esterification reaction of ethylene oxide (EO) and methacrylic acid (MAA). The process technology threshold is relatively high, especially the production of high-purity products has strict requirements on catalysts, reaction conditions and post-processing processes. Its physical properties are colorless and transparent liquids with a boiling point of about 95°C, a density of 1.074 g/cm³, and a flash point of 108°C. It is easy to flow and miscible with water at room temperature, but it needs to be stored at low temperature (<10°C) and in the presence of inhibitors to prevent self-polymerization.

From the perspective of chemical stability, Hydroxyethyl Methacrylate is sensitive to light and heat, and is prone to free radical polymerization under ultraviolet or high temperature conditions. This feature is both its application advantage and increases the challenges of storage and transportation. To inhibit self-polymerization, industrial products usually add 200±50 ppm of MEHQ inhibitor and use inert gas protection packaging. In terms of toxicity, Hydroxyethyl Methacrylate is a low-toxic substance. Rat experiments show that its inhalation toxicity is low, but direct contact should still be avoided. Protective equipment should be worn during operation and ventilation should be ensured.

The global Hydroxyethyl Methacrylate production pattern shows obvious regional concentration. Before 2020, high-end production capacity was mainly distributed in Japan, Germany and the United States, among which Mitsubishi Chemical of Japan occupied a dominant position, and most of its products were exported to emerging markets such as my country. In the early days, Chinese local enterprises mainly focused on low-end products (purity 95-96%), but in recent years, with the breakthrough of technical barriers by enterprises such as Wanhua Chemical, relying on self-developed processes and self-sufficiency of raw materials, they have achieved large-scale production of high-end Hydroxyethyl Methacrylate (purity ≥98%), significantly reducing dependence on imports.

Hydroxyethyl Methacrylate’s key competitive edge lies in its dual-functional design: vinyl groups provide efficient polymerization capabilities while the hydroxyl groups act as anchor points for chemical modification later. This “polymerization-functionalization” dual path makes Hydroxyethyl Methacrylate highly flexible when it comes to copolymerization, grafting and cross-linking reactions – such as automotive coatings where Hydroxyethyl Methacrylate not only participates in film formation but can react with isocyanate curing agents to create three-dimensional networks which improve hardness and toughness simultaneously thereby simultaneously improving hardness and toughness of coatings.

Hydroxyethyl Methacrylate self-polymers have long been recognized for their biocompatibility and safety, making them indispensable in medical applications. Their interfacial compatibility with human tissues, no inflammatory response following long-term implant, reduced monomer residue levels to sub ppm levels through strict process control measures and significantly less cytotoxicity compared with other acrylate monomers.

Hydroxyethyl Methacrylate copolymers offer excellent weather resistance thanks to the hydroxyl groups which capture free radicals and delay photo-oxidative degradation, particularly for environments exposed to UV radiation. When tested against traditional styrene-acrylic resin coatings, their QUV aging test revealed that its gloss retention rate remained over 90% after 2000 hours compared with traditional styrene-acrylic resin systems; processing adaptability can be seen through their copolymerization compatibility with different monomers; whether using water- or solvent-based systems they allow precise control of parameters such as viscosity, Tg by altering feed ratio.

Economy wise, domestic mass production of high-end Hydroxyethyl Methacrylate has broken Japanese and German companies’ price monopoly of this commodity. Wanhua Chemical’s integrated production model reduces raw material costs by more than 30 % while product cost performance significantly outshines that of imported products – this has promoted cost optimization across downstream industries such as automotive coatings and electronic adhesives as well. Furthermore, Hydroxyethyl Methacrylate boasts few synthetic by-products with its high atomic economy aligning it with green chemistry’s trend development trend as well as having great potential in developing sustainable materials in future.

Contact Us

Product Package picture:

Related References:

chemicalbook-Hydroxyethyl Methacrylate

Hydroxyethyl Methacrylate Manufacturer

Contact Us

As an experienced Hydroxyethyl Methacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Hydroxyethyl Methacrylate CAS 868-77-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.