Grubbs Catalyst 2Nd Generation CAS 246047-72-3

Grubbs Catalyst 2Nd Generation CAS 246047-72-3 With Best Quality

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Grubbs Catalyst 2Nd Generation

CAS: 246047-72-3

MOQ: 1KG

Directory Guidance on Grubbs Catalyst 2Nd Generation

Product Introduction:

Grubbs Catalyst 2Nd Generation is a ruthenium carbene complex catalyst discovered by Nobel Prize winner in Chemistry Robert Grubbs, mainly used for olefin metathesis reaction. This catalyst has the following properties:

• High activity and stability: Grubbs Catalyst 2Nd Generation shows high stability during the reaction and is not easy to decompose. Compared with the first generation catalyst, it has stronger stability and higher reactivity.

• Broad substrate applicability: This catalyst can be applied to a variety of substrates, including sterically demanding or deactivated olefins, such as 1,1-disubstituted olefins and α,β-unsaturated carbonyl compounds.

• Good solubility: Grubbs Catalyst 2Nd Generation is easily soluble in organic solvents and is usually used in CH2Cl2, benzene or toluene solutions, which makes it extremely flexible and applicable in organic synthesis.

• Sensitivity to air and water: Although Grubbs Catalyst 2Nd Generation is sensitive to air and water and needs to be used under inert gas protection, it is relatively stable under dry conditions and gradually loses its activity when exposed to air.

• Wide application: Grubbs Catalyst 2Nd Generation is used to construct the core structure of complex molecules in organic synthesis methodology research, especially in the fields of drug synthesis and natural product synthesis.

In summary, Grubbs Catalyst 2Nd Generation has become one of the indispensable tools in modern organic chemistry research with its superior activity, stability and tolerance to complex molecular functional groups.

Basic Info:

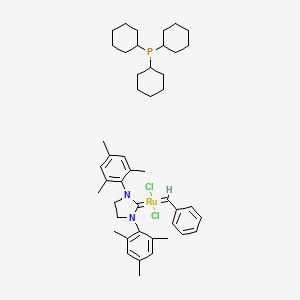

Chemical Structure

Melting point | 143.5-148.5 °C(lit.) |

storage temp. | 2-8°C |

form | Solid |

Nature and Specifications:

| Item | Specification |

| Product Name | Grubbs Catalyst 2Nd Generation |

| CAS No. | 246047-72-3 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| solubility | Chloroform (Slightly), Ethyl Acetate (Slightly), Methanol (Very Slightly, Heated) |

| form | Solid |

| color | Brown to Very Dark Brown to Very Dark Red |

What Are The Uses of Grubbs Catalyst 2Nd Generation

Product service:

Grubbs Catalyst 2Nd Generation plays an extremely important role in the field of chemical synthesis due to its high efficiency, stability and versatility, and its application prospects are broad, especially in synthetic chemistry, materials science and drug development.

1. Olefin ring-opening polymerization reaction

Grubbs Catalyst 2Nd Generation plays an important role in olefin ring-opening polymerization (ROMP) and can effectively catalyze the polymerization of various cycloolefins. The polymers generated by this reaction are often used to prepare high-performance plastics, elastomers and supramolecular materials.

For example, it shows good activity and low catalyst consumption in the synthesis of polymer materials such as polybutadiene and polycyclopentene. The high efficiency of the ROMP reaction makes Grubbs Catalyst 2Nd Generation an ideal tool for the preparation of new functional materials.

2. Olefin cross-coupling reaction

In the olefin cross-coupling reaction, Grubbs Catalyst 2Nd Generation can effectively promote the double bond exchange of two different olefin molecules to generate new olefin products.

This reaction is widely used in structural modification and molecular construction in organic synthesis, especially in the synthesis of natural products and pharmaceutical molecules with complex structures, which can achieve an efficient construction process.

3. Asymmetric synthesis and medicinal chemistry

Because Grubbs Catalyst 2Nd Generation is highly selective for certain special reactions, it has significant advantages in asymmetric synthesis. Catalysts can selectively generate specific chiral centers during the synthesis process, which is particularly important for the design and synthesis of drugs.

For example, Grubbs Catalyst 2Nd Generation plays a key role in the synthesis of certain anticancer drugs, helping to synthesize specific stereochemical structures in drug molecules by catalyzing highly selective reactions.

4. Synthesis of new functional materials

Grubbs Catalyst 2Nd Generation is also widely used in the synthesis of new functional materials, especially in the synthesis of materials with high conductivity, high thermal stability or responsiveness.

For example, it is used to synthesize self-healing materials, molecular sensors, and liquid crystal polymers, which have important applications in electronics, optics, and energy.

5. Molecular imprinting and supramolecular chemistry

Grubbs Catalyst 2Nd Generation also plays an important role in the field of molecular imprinting polymers (MIPs) and supramolecular chemistry.

By using this catalyst, polymer materials with specific recognition functions can be synthesized through the principle of molecular recognition. These materials can be used in biosensors, drug delivery systems, and environmental monitoring.

6. Academic research

Grubbs Catalyst 2Nd Generation is widely used in academic research, including the study of the properties of the catalyst itself, the exploration of reaction mechanisms, and the development of new reactions.

These studies not only promote the development of organic synthesis methodology, but also have a profound impact on the design and synthesis of new materials.

In general, Grubbs Catalyst 2Nd Generation has become an indispensable catalyst in the fields of organic synthesis, drug synthesis, and material development due to its excellent catalytic performance, especially in the cross-coupling reaction of olefins, ring-opening polymerization reaction, and asymmetric synthesis.

Precautions for use Grubbs Catalyst 2Nd Generation

When using Grubbs Catalyst 2Nd Generation, some operating details and reaction conditions need to be paid attention to to ensure the high efficiency of the reaction and the stability of the catalyst.

1. Air and water sensitivity

Grubbs Catalyst 2Nd Generation is very sensitive to oxygen and moisture in the air and is prone to decomposition reactions. The metal center of the catalyst (usually molybdenum or tungsten) will react with water and oxygen, resulting in catalyst deactivation or reduced reaction efficiency.

Therefore, it is necessary to operate under strictly anhydrous and oxygen-free conditions when using it. Common practices are:

– Carry out the reaction under nitrogen or inert gas (such as argon) atmosphere.

– Use desiccant and dry solvent, and ensure that the experimental apparatus is free of water.

– It is best to strictly dehydrate the reactants and solvents, or use anhydrous solvents.

2. Catalyst storage

Due to the sensitivity of the catalyst to air and water, Grubbs Catalyst 2Nd Generation should be stored in a sealed container and placed in a low-temperature dry place. In order to extend the service life of the catalyst, avoid long-term exposure to air and minimize the exposure time of the catalyst.

3. Choice of reaction solvent

Choosing a suitable solvent is crucial to the success of the reaction. Generally, Grubbs Catalyst 2Nd Generation perform better in non-polar solvents (such as chloroform, dichloromethane, etc.).

For some reactions, polar solvents such as ether solvents (e.g., tetrahydrofuran, THF) can also be used, but it is necessary to ensure that the solvent itself is clean and anhydrous. For efficient catalytic reactions, avoid using aqueous solvents or solvents with strong polarity.

4. Catalyst dosage

Grubbs Catalyst 2Nd Generation have high catalytic activity in many reactions, so the amount of catalyst needs to be carefully controlled. Excessive catalyst may cause side reactions or produce unwanted byproducts. Generally, the amount of catalyst is controlled between 1-5% by molar ratio, depending on the type of reaction and the nature of the substrate.

5. Reaction temperature

Grubbs Catalyst 2Nd Generation usually work better at room temperature or slightly higher temperatures. Excessive temperatures may cause catalyst degradation or promote the occurrence of side reactions.

In order to ensure the efficient progress of the catalytic reaction, it is best to control the temperature within an appropriate range. For more active reactions, low temperatures (0–30°C) may help improve selectivity and reduce the generation of side reactions.

6. Substrate selection

Grubbs Catalyst 2Nd Generation are particularly suitable for olefin compounds, but the structure and properties of the reaction substrates will also affect the catalytic effect.

For example, some olefins containing strong electron-attracting groups may inhibit the activity of the catalyst, and some complex polyolefin substrates may require optimized reaction conditions to obtain the desired product. The higher the substrate purity, the higher the success rate of the catalytic reaction.

7. Monitoring and termination of the reaction

Since catalytic reactions are usually efficient and rapid, when performing Grubbs catalytic reactions, the progress of the reaction needs to be closely monitored to ensure that the reaction does not stop prematurely or proceed excessively.

The reaction can be monitored in real time by methods such as gas chromatography (GC) and thin layer chromatography (TLC). For some occasions where the reaction needs to be terminated, the reaction can be stopped by adding an appropriate amount of inhibitor (such as water or alcohol) or by cooling to slow down the reaction rate.

8. Control of side reactions

Although Grubbs Catalyst 2Nd Generation usually have high selectivity, side reactions (such as self-coupling reactions, olefin isomerization, etc.) may also occur under certain reaction conditions. Therefore, when selecting reaction conditions, attention should be paid to optimizing the reaction temperature, solvent, substrate concentration, etc. to reduce the generation of side reactions.

9. Recovery and reuse of catalysts

Grubbs Catalyst 2Nd Generation can be recovered and reused by certain methods, especially in large-scale synthesis. Usually, the recovery of the catalyst can be carried out by methods such as solvent extraction, filtration or recrystallization. When used multiple times, the activity of the catalyst may decrease, so it is necessary to check the efficiency of the catalyst regularly and perform necessary reactivation.

As an efficient catalyst, Grubbs Catalyst 2Nd Generation has a wide range of application potential in reactions such as cross-coupling and ring-opening polymerization of olefins.

However, when using it, it is necessary to pay attention to maintaining an anhydrous and oxygen-free environment, selecting appropriate solvents and reaction conditions, and reasonably controlling the amount of catalyst and reaction temperature to ensure the high efficiency of the catalytic reaction and the selectivity of the product. At the same time, monitoring the generation of side reactions is also the key to ensure the smooth progress of the reaction.

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Contact Us

Product picture:

Product Package picture:

Related References:

chemicalbook-Grubbs Catalyst 2Nd Generation

Grubbs Catalyst 2Nd Generation Manufacturer

Contact Us

As an experienced Grubbs Catalyst 2Nd Generation manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Grubbs Catalyst 2Nd Generation CAS 246047-72-3 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.