Dimethyldimethoxysilane CAS 1112-39-6

Factory Dimethyldimethoxysilane CAS 1112-39-6

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dimethyldimethoxysilane

CAS: 1112-39-6

MOQ: 1KG

Directory Guidance on Dimethyldimethoxysilane

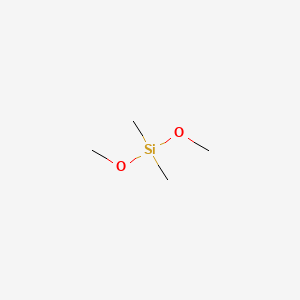

Chemical Structure

Basic Info:

| Melting point | -80°C |

| Boiling point | 81.4 °C(lit.) |

| density | 0.88 g/mL at 25 °C(lit.) |

| vapor pressure | 7-12790Pa at 20-25℃ |

| refractive index | n20/D 1.369(lit.) |

| Fp | 50 °F |

Product Introduction:

Dimethyldimethoxysilane is a colorless to slightly yellow transparent liquid with low volatility and good chemical stability. Its density usually fluctuates between 0.86–0.93 g/cm³, and the specific value may vary depending on purity or measurement conditions. The compound has a wide boiling point range (81.4℃–114℃) and a flash point of about 12℃, indicating that it is relatively stable at room temperature, but there is a risk of flammability in high temperature or open flame environments. It is miscible with a variety of organic solvents such as alcohols, ethers, and ketones, which facilitates its application in industry. From the perspective of molecular structure, the silicon atom of Dimethyldimethoxysilane is connected by two methyl groups and two methoxy groups. This structure gives it unique reactivity and interface compatibility, which not only retains the heat resistance of organosilicon compounds, but also enhances its ability to bind to inorganic materials through the introduction of methoxy groups.

In terms of chemical properties, the core properties of Dimethyldimethoxysilane come from the synergistic effect of silicon-oxygen bonds and silicon-carbon bonds. methoxy (-OCH₃) can be hydrolyzed under acidic or alkaline conditions to generate silanol (-Si(OH)₂), which then forms a siloxane network through condensation reaction. This property makes it an important precursor for the preparation of silicone polymers, such as structure control agents or chain extenders for silicone rubber. the methyl group (-CH₃) in its molecule can provide hydrophobicity and flexibility, while the methoxy group reacts with the hydroxyl group on the surface of inorganic materials to achieve chemical bonding between the organic and inorganic interfaces, thereby enhancing the mechanical properties and durability of the composite material.

The main method for synthesizing dimethyldimethoxysilane is through the alcoholysis reaction of dimethyldichlorosilane and methanol. This process is usually carried out in the presence of an alkaline catalyst (such as sodium hydroxide or ammonia), and the hydrogen chloride generated by the reaction needs to be treated by an absorption device to reduce environmental pollution. After the reaction is completed, a high-purity product can be obtained through purification processes such as distillation. In addition to the alcoholysis method, direct synthesis and Grignard reagent methods have also been explored, but the alcoholysis route is still the main method in industrial production because of its low cost and mature process.

Nature and Specifications:

| Item | Specification |

| Product Name | Dimethyldimethoxysilane |

| CAS No. | 1112-39-6 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | Store below +30°C. |

| form | liquid |

| Specific Gravity | 0.88 |

| color | Colorless to Almost colorless |

| Water Solubility | decomposes |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Dimethyldimethoxysilane occupies an important position in the field of organic silicon materials. As a structural controller of silicone rubber, it can adjust the crosslinking density of polymers and improve the tensile strength and resilience of materials. In addition, Dimethyldimethoxysilane is also used as a modifier for silicone oil and silicone resin, and the adhesion and weather resistance of the product are enhanced by introducing methoxy groups.

In the field of composite materials, the coupling effect of Dimethyldimethoxysilane significantly improves the bonding effect between inorganic fillers and organic matrices. For example, after surface treatment of fillers such as silica or aluminum hydroxide, agglomeration can be effectively reduced, while enhancing the interfacial bonding with matrices such as plastics and rubber. This feature makes it widely used in reinforcing engineering plastics such as nylon and epoxy resin, and the material is particularly outstanding in impact resistance and wear resistance.

Paint and coating industry is another important application direction of this compound. Siloxane-based coatings with dimethyldimethoxysilane not only have excellent anti-corrosion capabilities, but also achieve self-cleaning functions by reducing surface energy. Such coatings perform well in areas such as metal protection and building waterproofing, especially in acidic or hot and humid environments, where their chemical corrosion resistance far exceeds that of traditional organic coatings. In addition, its low volatility and film-forming stability also make it an ideal choice for electronic device packaging coatings.

In the field of adhesives, dimethyldimethoxysilane improves the temperature resistance and durability of adhesives by participating in cross-linking reactions. For example, in high-temperature sealants, its methoxy groups react with hydroxyl groups on the surface of the substrate to form chemical bonds, allowing the adhesive layer to maintain bonding strength above 200°C. At the same time, its hydrophobic properties can effectively prevent moisture penetration and extend the service life of adhesives in outdoor environments.

The demand for dimethyldimethoxysilane in electronic packaging materials is also growing. Its high-purity products (such as chloride ion content ≤2 mg/kg) can be used in the preparation of semiconductor packaging adhesives, and the reliability of electronic components can be improved by optimizing the dielectric constant and thermal expansion coefficient.

Emerging applications in the field of environmental protection are also worthy of attention. For example, the compatibility of Dimethyldimethoxysilane with bio-based polymers can be used to develop biodegradable silicon materials to reduce the environmental load of traditional petrochemical products. In addition, in water treatment membrane materials, surface modification can be used to improve the membrane’s pollution resistance and separation efficiency, providing innovative solutions for industrial wastewater treatment.

The core advantage of dimethyldimethoxysilane comes from its unique molecular structure. The high bond energy of the silicon-oxygen bond (about 452 kJ/mol) gives the material excellent thermal stability, making it stable in the range of -50℃–200℃, far exceeding most organic compounds. At the same time, the high reactivity of the methoxy group enables it to participate in hydrolysis and condensation to form a three-dimensional network structure, and to chemically bond with the surface of inorganic materials to achieve cross-interface performance enhancement. The integration of this dual function in a single molecule significantly reduces the complexity of industrial formulations.

From a process perspective, the synthesis route of dimethyldimethoxysilane is mature and easy to scale. The reaction conditions of the alcoholysis method are mild (usually 60℃–80℃), and the catalyst can be recycled, which is in line with the development direction of green chemistry. The production process is less corrosive to equipment, and high-purity products of ≥99% can be obtained by conventional means such as distillation, meeting the stringent requirements of electronic-grade materials. In addition, its low volatility (boiling point>80℃) reduces volatile losses during production and use, reducing safety risks and waste of raw materials.

In terms of compatibility, Dimethyldimethoxysilane shows a wide range of applicability. It is miscible with a variety of solvents such as alcohols, ketones, and esters, making it easy to disperse in different systems. For composite materials with large polarity differences (such as rubber and glass fiber), the methyl and methoxy groups in its molecules can interact with organic and inorganic phases respectively, effectively relieving interfacial stress and avoiding stratification or cracking. This “bridge” effect makes it irreplaceable in high-end fields such as lightweight automotive materials and aerospace composites.

Economic benefits are also its important advantage. Compared with other silane coupling agents (such as aminosilane or epoxysilane), Dimethyldimethoxysilane has lower raw material costs and does not require precious metal catalysts during the synthesis process. In the production of silicone rubber, adding 1%-3% of this compound can significantly improve the processing performance and mechanical indicators of the finished product, with a very high input-output ratio. In addition, its storage stability of more than three years reduces storage pressure, making it particularly suitable for industrial scenarios that require long-term stocking.

The balance between environmental protection and safety performance further enhances the competitiveness of Dimethyldimethoxysilane products. Although it is a flammable liquid, its flash point is higher than that of most petroleum solvents (such as acetone at -20°C), and the risks of transportation and storage are relatively controllable. The hydrolysis products are mainly methanol and silicon dioxide, the latter of which is harmless to the environment, while methanol can be recycled through the recycling system, meeting the requirements of clean production. In terms of replacing halogen-containing silanes, the promotion of this compound will help reduce the emission of toxic by-products and promote the sustainable development of the chemical industry.

Contact Us

Product Package picture:

Related References:

chemicalbook-Dimethyldimethoxysilane

Dimethyldimethoxysilane Manufacturer

Contact Us

As an experienced Dimethyldimethoxysilane manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dimethyldimethoxysilane CAS 1112-39-6 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.