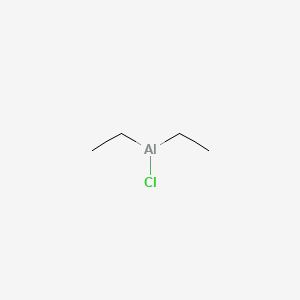

Diethylaluminum Chloride CAS 96-10-6

Factory wholesale Diethylaluminum Chloride CAS 96-10-6

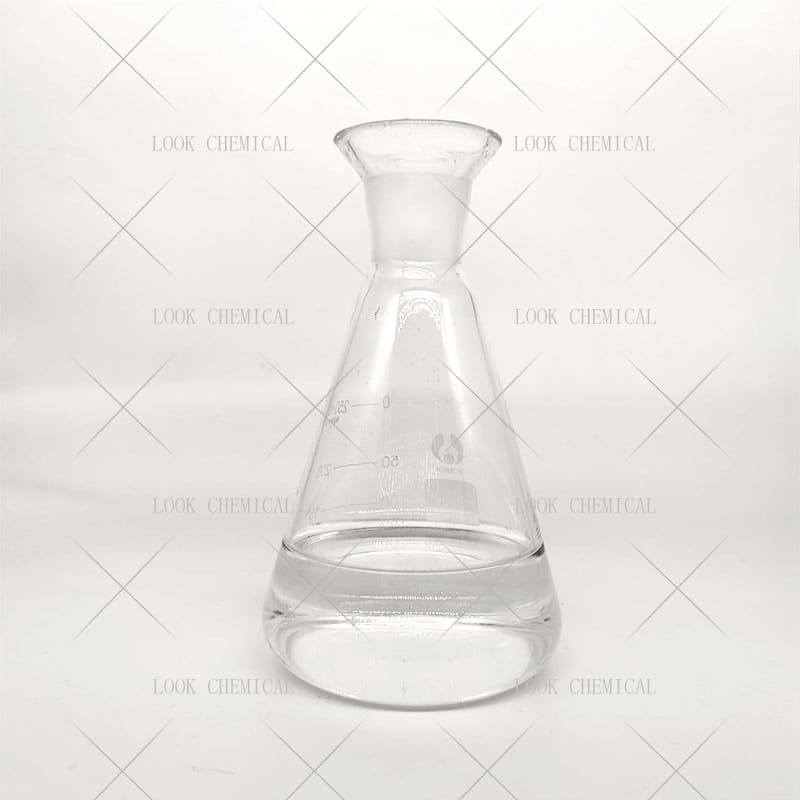

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diethylaluminum Chloride

CAS: 96-10-6

MOQ: 1KG

Directory Guidance on Diethylaluminum Chloride

Chemical Structure

Basic Info:

| Melting point | -85°C |

| Boiling point | 125°C 50mm |

| density | 0.887 g/mL at 25 °C |

| vapor pressure | 3 mmHg ( 60 °C) |

| Fp | −9 °F |

| storage temp. | 0-6°C |

| solubility | Miscible with hexane. |

Product Introduction:

Diethylaluminum Chloride (DEAC), whose chemical formula is (C₂H₅)₂AlCl, is an important organoaluminum compound. The substance consists of two ethyl groups and a chlorine atom combined with aluminum atoms through covalent bonds, and appears as a colorless or light yellow liquid with strong hygroscopic and spontaneous combustion.

From a synthetic point of view, Diethylaluminum Chloride is mainly prepared by the direct reaction of aluminum powder and ethyl chloride under high temperature and pressure, or by the displacement reaction of triethylaluminum and hydrogen chloride. Sodium or magnesium is often used as a reducing agent in industrial production to improve reaction efficiency and product purity. Due to the change in the oxidation state of aluminum and the steric hindrance effect of the organic ligand, the temperature, pressure and raw material ratio must be strictly controlled during the synthesis process to avoid impurities produced by side reactions. In addition, its preparation process has high requirements for equipment materials, and stainless steel or glass-lined reactors are usually required to resist erosion by corrosive media.

In terms of physical and chemical properties, Diethylaluminum Chloride has a boiling point of about 208°C and a density of 1.01-1.05 g/cm³, and is easily soluble in hydrocarbon solvents such as hexane and toluene, but may decompose in polar solvents. Its chemical properties are extremely active, water or air will be rapidly hydrolyzed or oxidized, release a lot of heat and generate hydrogen chloride gas and alumina residue. Therefore, storage and transportation should be carried out under the protection of inert gases (such as nitrogen or argon) and contact with oxygen-containing and hydroxy-containing compounds should be avoided.

From a safety point of view, Diethylaluminum Chloride is classified as a high-risk chemical. Its spontaneous combustion requires that operators wear protective gear and handle it in an oxygen-free environment. When leaking, it should be covered with dry sand, and it is strictly prohibited to wash with water. Despite the high risk, its key role in industrial catalysis, polymer synthesis and other fields still makes it an irreplaceable chemical. With the progress of process technology, the improvement research on its stability and safety has been continuously promoted in recent years.

Nature and Specifications:

| Item | Specification |

| Product Name | Diethylaluminum Chloride |

| CAS No. | 96-10-6 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | Solution |

| color | Colorless |

| Specific Gravity | 0.711 (20/4℃) |

| Water Solubility | reac H2O [CRC10] |

| Sensitive | Air & Moisture Sensitive |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Diethylaluminum Chloride is frequently employed as the core component of Ziegler-Natta catalysts due to its strong Lewis acidity and coordination properties. Transition metal compounds (e.g. halides of titanium and vanadium) can form active centers which greatly enhance both rate and selectivity of olefin polymerization. As an example, in industrial production of polyethylene and polypropylene, its molecular weight distribution and stereoregularity can be precisely controlled by adjusting the molar ratio of Diethylaluminum Chloride to its main catalyst, thus optimizing mechanical properties and processing characteristics of material. Furthermore, Diethylaluminum Chloride may also be used for directed polymerization of conjugated diolefins to provide technical assistance for creating special rubbers.

Diethylaluminum Chloride, as an alkylating and reducing agent, is widely employed in organic synthesis for carbon-carbon bond formation. It can speed the conversion of aldehydes and ketones to secondary or tertiary alcohols while binding with chiral ligands for asymmetric synthesis to produce highly enantioselective products – this makes Diethylaluminum Chloride ideal for drug intermediate synthesis since complex molecular scaffolds such as steroids or alkaloids must be constructed.

In the field of surface treatment and material modification, Diethylaluminum Chloride shows unique advantages. It can chemically react with the metal surface to form a dense protective film, thereby improving the corrosion resistance and wear resistance of the metal. For example, in the surface treatment of aluminum alloys, Diethylaluminum Chloride reacts with the oxide layer on the surface of aluminum to generate an aluminum oxide layer with higher stability, significantly extending the service life of the material. In addition, in the preparation of some functional materials, it can change the surface properties of the material through chemical modification, such as hydrophilic, hydrophobic, etc., so as to meet the needs of specific application scenarios.

Diethylaluminum Chloride has long been used as an essential catalyst or intermediate in pharmaceutical and pesticide industries to synthesize various active ingredients, from antibiotics to insecticides and beyond. As part of an antibiotic synthetic route, Diethylaluminum Chloride helps facilitate formation of b-lactam rings; for insecticide production it is used to form heterocyclic structures containing phosphorus or sulfur; while its synergistic effect with silane reagents allows it to create functional siloxanes which provide slow release systems or agricultural auxiliaries – adding yet another dimension of production!

Diethylaluminum Chloride has become an integral component of new energy materials over time, particularly lithium-ion batteries and fuel cells. When added as an electrolyte additive it can improve electrode/electrolyte interface stability as well as inhibit dendrite growth; when used in catalytic layer fuel cells with noble metal nanoparticles it increases oxygen reduction reaction efficiency, thus further realizing its potential within new energy storage systems. As clean energy technology develops so do DEAC’s applications.

Diethylaluminum Chloride shows high reactivity and selectivity in chemical reactions, which gives it significant advantages in the field of organic synthesis and catalysis. Compared with traditional alkylating reagents, Diethylaluminum Chloride can react more efficiently with carbonyl compounds to produce target products. For example, in the synthesis of certain alcohols, its reactivity is several times that of traditional reagents, while the reaction selectivity is higher and fewer byproducts are produced. This high efficiency and selectivity not only improves the reaction yield, but also reduces the difficulty of separation and purification, thus significantly reducing the production cost.

Safety and environmental protection: Although Diethylaluminum Chloride itself is highly reactive, modern processes have developed several stabilization technologies to control its volatility. Microencapsulated or ionic liquid carrier agents can significantly lower spontaneous combustion risk while maintaining catalytic activity; any by-products generated during production (such as hydrogen chloride) can be recycled through closed loop recovery systems in keeping with green chemistry principles; additionally its bioaccumulation rate is much lower compared with some heavy metal catalysts, and its environmental impacts more controllable by strict controls than with some metal catalysts containing heavy metals.

Diethylaluminum Chloride’s molecular modifiability provides an immense opportunity for research and development of functionalized derivatives, with numerous possibilities presented by its molecular modification. By adding different substituents or combining it with different metals, new catalysts for specific reactions can be developed – for instance by combining DEAC with rare earth metals which improve regional selectivity of copolymerization reactions or hybridising it with transition metals which expand asymmetric catalysis applications; such modular design provides theoretical foundation for future innovation of catalytic systems.

Contact Us

Product Package picture:

Related References:

chemicalbook-Diethylaluminum Chloride

Diethylaluminum Chloride Manufacturer

Contact Us

As an experienced Diethylaluminum Chloride manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diethylaluminum Chloride CAS 96-10-6 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.