Dibutyl Phthalate Liquid CAS 84-74-2

High Quality Dibutyl Phthalate Liquid CAS 84-74-2

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Dibutyl Phthalate

CAS: 84-74-2

MOQ: 1KG

Directory Guidance on Dibutyl Phthalate

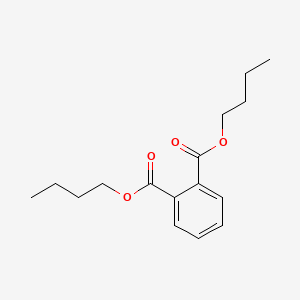

Chemical Structure

Basic Info:

| Melting point | -35 °C (lit.) |

| Boiling point | 340 °C (lit.) |

| density | 1.043 g/mL at 25 °C (lit.) |

| vapor density | 9.6 (vs air) |

| vapor pressure | 1 mm Hg ( 147 °C) |

| refractive index | n20/D 1.492(lit.) |

| Fp | 340 °F |

Product Introduction:

Dibutyl Phthalate Liquid, more commonly referred to as DBP, is an extremely useful plasticizer. Primarily utilized in PVC plastic materials to improve flexibility and durability, its chemical formula is C16H22O4 with an approximate molecular weight of 278.34 g/mol and molecular weight being 278.34. DBP appears as either colorless or slightly yellow oily liquid that has an aromatic smell; insoluble in water but soluble with organic solvents like alcohols, ethers or benzene. With an approximate boiling point of 340degC and good stability at room temperatures compared with many of its peers such as DDE

Dibutyl Phthalate Liquid (DBP) is an essential plasticizer, widely utilized to increase flexibility and durability of plastics. Composed of two butyl groups connected by phthalic acid groups, Dibutyl Phthalate Liquid plays an essential role in plastic processing; especially when manufacturing polyvinyl chloride (PVC). DBP provides softness and plasticity while simultaneously improving physical properties such as brittleness reduction, flexibility improvement and low temperature resistance; it is widely utilized by products like flooring, wallpaper soles cables etc.

Dibutyl Phthalate Liquid has long been utilized within the plastics industry; however, due to its volatility and water extraction properties it has gradually seen less use over time. Dibutyl Phthalate Liquid’s highly volatile nature means its effects may weaken over time leading to reduced plasticizing action of material used and ultimately impacting its service life and lifespan.

Dibutyl Phthalate Liquid has low animal oral lethal dose50 values and may pose little to no threat to people or the environment, with an average animal oral LD50 being 8g/kg; some individuals may also be allergic to DBP; the maximum allowable concentration in air being 5 mg/m3. While many countries allow its use in plastic food-contact products, extra caution must still be exercised when handling Dibutyl Phthalate Liquid to ensure minimal adverse impacts to both people and environments.

Dibutyl Phthalate Liquid should be stored and transported according to regulations for general dangerous goods, usually packed in iron drums and stored in a dry and ventilated place that’s protected from rain, sunlight and fire. Furthermore, any packaging used should comply with environmental standards for general dangerous goods storage and transportation.

Nature and Specifications:

| Item | Specification |

| Product Name | Dibutyl Phthalate |

| CAS No. | 84-74-2 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | Liquid |

| color | APHA: ≤10 |

| Specific Gravity | 1.049 (20/20℃) |

| Odor | odorless |

| Relative polarity | 0.272 |

| explosive limit | 0.47%, 236°F |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Dibutyl Phthalate Liquid is an ubiquitous plasticizer in industrial production, specifically in plastics, rubber, paints and coatings production. As an effective plasticizer it plays a pivotal role in improving material flexibility, processability and low temperature resistance – essential requirements when producing various products.

1. Plasticizer for Polyvinyl Chloride (PVC)

Dibutyl Phthalate Liquid has become one of the most frequently utilized applications of Dibutyl Phthalate Liquid as it serves as a plasticizer for Polyvinyl Chloride (PVC) plastics, making PVC commonly found in construction, automobiles, homes and daily life (e.g. piping systems, cable sheaths flooring curtains etc).

Dibutyl Phthalate Liquid lowers the glass transition temperature of PVC, making it more flexible, easier to process, and increasing low-temperature resistance. It gives products required elasticity and softness while protecting from becoming brittle or cracking; making it particularly suitable for products requiring long-term durability with flexible strength requirements.

2. Plasticizer for Rubber and Synthetic Rubber

In the rubber industry, Dibutyl Phthalate Liquid can serve as both a plasticizer and process aid to enhance rubber’s processing properties and fill molding molds more easily during molding processes while still maintaining good elasticity and wear resistance. Dibutyl Phthalate Liquid is widely utilized during synthetic rubber production processes as its flexibility, low temperature performance and aging resistance improve drastically – therefore being widely utilized across tires, soles, conveyor belts and automotive seals among many other uses.

3. Paints and Coatings

Dibutyl Phthalate Liquid is widely utilized as a plasticizer in the coating industry, particularly nitrocellulose coatings and paints. It enhances fluidity, ductility, adhesion, uniform application, durability, flexibility and flexibility of these coatings – features which make them popular choices when creating automotive, furniture or protective coatings for wood or metal surfaces.

4. Nitrocellulose and Fiber Materials

Dibutyl Phthalate Liquid is used as a plasticizer during production of nitrocellulose, making it more suitable for coatings, varnishes and other uses. Additionally, Dibutyl Phthalate Liquid enhances flexibility of cellulose ether materials (ethyl cellulose for instance), enhances plasticity and processing performance – these benefits make Dibutyl Phthalate Liquid popularly utilized when working with synthetic fibers, fabric processing or textile coatings where high flexibility or low temperature performance are demanded.

5. Dibutyl Phthalate Liquid’s Use in Other Plastics

Dibutyl Phthalate Liquid can also be used to plasticize other types of plastic, including polyvinyl acetate (PVA), alkyd resins and more complex manufacturing processes and finished product requirements – for instance improving polyvinyl acetate’s thermoplasticity to make adhesives and sealants more suitable.

6.Softener For Textiles And Leather

Dibutyl Phthalate Liquid can also be used as a softener for textiles and leather production processes, helping increase softness while simultaneously improving durability of leather products, increasing comfort levels and prolonging service lives. Furthermore, textile treatments that need additional softness or wear resistance may benefit from its application as a softener as well.

7. Additional Applications

Dibutyl Phthalate Liquid can also be used as a solvent in perfumes and fragrances to increase their stability and decrease volatility, as well as providing better volatility control.

Agriculture: Dibutyl Phthalate Liquid can also be used as a solvent or additive in some agricultural chemicals (including pesticides) in order to increase fluidity and stability of these products.

Insulation materials and wires and cables: Dibutyl Phthalate Liquid can be used in the insulation layer of wires and cables to increase their flexibility while protecting them from temperature changes that could make them brittle over time. Due to its excellent low temperature performance, DBP plasticized cables perform especially well under such circumstances.

1. Increase Flexibility

Dibutyl Phthalate Liquid can dramatically increase flexibility of plastics and rubber materials when used as a plasticizer, softening hard materials (like PVC) to become more bendable and flexible.

2. Low Temperature Resistance

Dibutyl Phthalate Liquid offers excellent low-temperature resistance properties, which can effectively improve material flexibility in low temperature environments, prevent plastics or rubber from hardening under cold conditions and extend product lifespan.

3. Excellent Processability

Dibutyl Phthalate Liquid boasts exceptional processing properties. In the plastic production process, particularly for polyvinyl chloride (PVC) production, Dibutyl Phthalate Liquid can significantly decrease viscosity of material being processed, thus making its processing smoother. Dibutyl Phthalate Liquid also enhances fluidity of plastics used during molding, extrusion and calendering processes while simultaneously decreasing frictional resistance and energy costs during processing.

4. Low Cost

Dibutyl Phthalate Liquid offers affordable plasticizer production costs, making it an economical solution in industries utilizing plasticizers in large amounts such as plastics and rubber manufacturing. It can also serve as an effective cost-cutting measure in industries where large volumes of plasticizers are required, such as the rubber industry.

5. Lower Volatility

Dibutyl Phthalate Liquid’s low volatility makes it ideal for long-term plasticizing effects and extended service life of plastic and rubber products by not evaporating quickly during use and providing lasting plasticizing effects. Dibutyl Phthalate Liquid also has better material persistence than highly volatile plasticizers, which means less frequent addition of additional plasticizers as needed to extend service life or extend their service lives.

6. Mix with Other Plasticizers Dibutyl Phthalate Liquid can also be combined with other types of plasticizers, including dioctyl phthalate (DOP) or other phosphate plasticizers to maximize formulations and customize product properties.

Contact Us

Product Package picture:

Related References:

chemicalbook-Dibutyl Phthalate

Dibutyl Phthalate Manufacturer

Contact Us

As an experienced Dibutyl Phthalate Liquid manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Dibutyl Phthalate Liquid CAS 84-74-2 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.