Chlorinated Rubber CAS 9006-03-5

Chlorinated Rubber CAS 9006-03-5 With Quality Wholesale

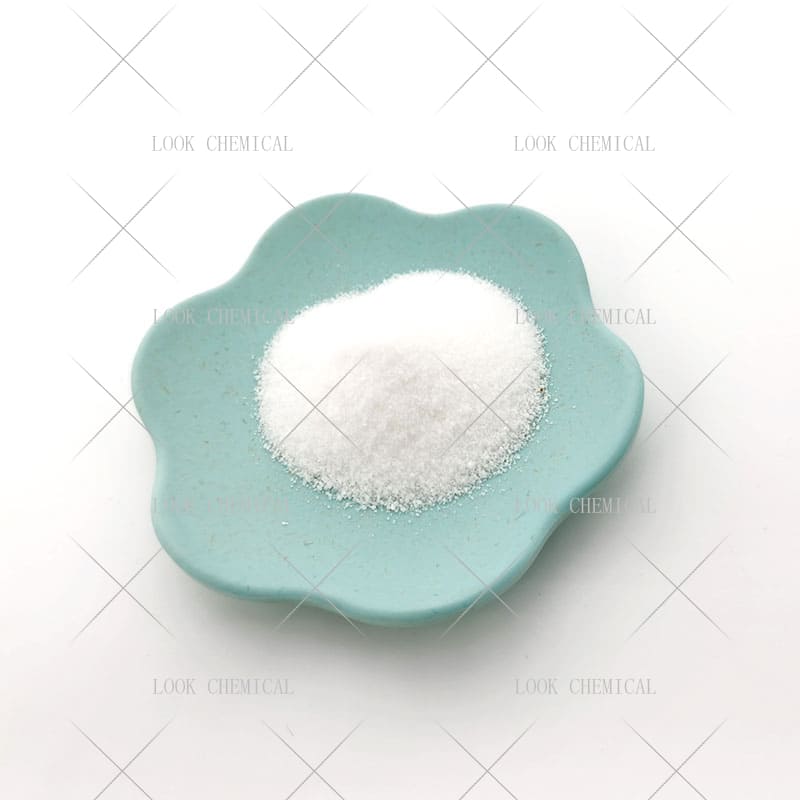

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Chlorinated Rubber

CAS: 9006-03-5

MOQ: 1KG

Directory Guidance on Chlorinated Rubber

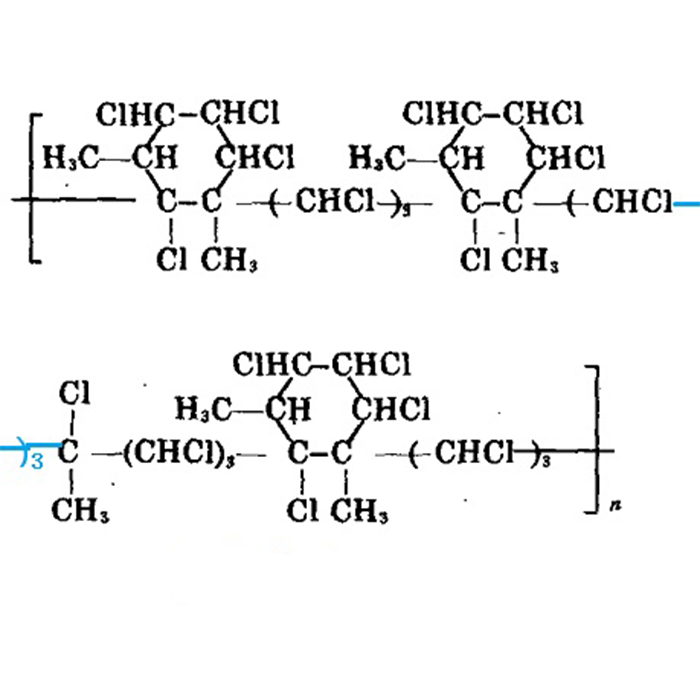

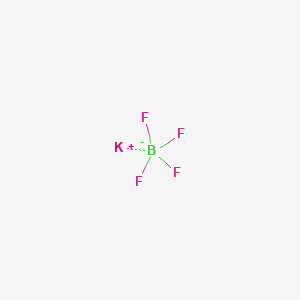

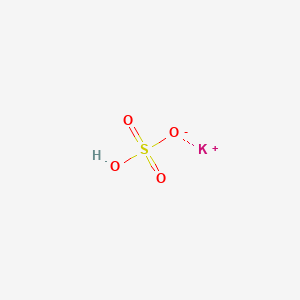

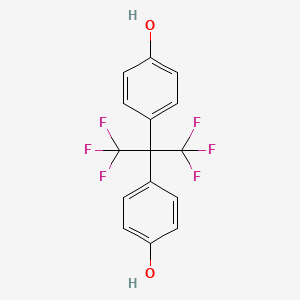

Chemical Structure

Basic Info:

| density | 1.43-1.50 |

| Fp | 135-140°C (dec.) |

| EPA Substance Registry System | Chlorinated rubber (9006-03-5) |

Product Introduction:

Chlorinated Rubber (CR) is a material prepared by chlorinating natural or synthetic rubber. During the chlorination process, hydrogen atoms in the rubber molecules are replaced in whole or in part by chlorine atoms, thereby obtaining a polymer with good weather resistance, chemical resistance and heat resistance. The degree of chlorination is usually between 40% and 70%. Usually, the preparation of chlorinated rubber is usually done by solution method rather than water suspension method or gas phase method, although these methods are available. The solution method is the most commonly used preferred method, while the other two methods have their own difficulties.

The main property of chlorinated rubber is good solvent resistance to oil, fuel, acid solution, alkali solution and some other chemicals. Due to its good weather resistance, it is widely used in outdoor coatings, industrial anticorrosive coatings and underwater coatings. In the construction industry, it is mainly used as waterproof coatings and sealing materials, thereby increasing the service life of the structure.

At the same time, chlorinated rubber also plays a good role in adhesives, tapes and other uses due to its strong adhesion and good processability. In addition, its elasticity and flexibility enable it to perform well even at low temperatures, making it particularly suitable for applications that require weather resistance or corrosion resistance. Brush-on liquid coatings are easy to apply and use. Usually, their processing uses solvents to form a usable liquid.

On the other hand, Chlorinated Rubber begins to decompose under high temperatures and strong ultraviolet rays, so it lacks UV resistance and thermal stability. In short, for many applications, the use environment requires special attention to its thermal stability and light stability. Usually, in order to further improve its performance, stabilizers must be added or it must be compounded with other materials.

Nature and Specifications:

| Item | Specification |

| Product Name | Chlorinated Rubber |

| CAS No. | 9006-03-5 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Type NO. | CR-10 |

| Chlorine Content (%, pbw) | 65%min |

| Density (g/ml) | 1.5 |

| Viscosity at 25ºC(10% in toluene, mPa.S) | 8-15 |

| Ash Content (%) | 0.6max |

| Moisture (%) | 0.6max |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Chloroprene is a synthetic polymer material made by reacting natural rubber or artificial rubber with chlorine. It has good weather resistance, chemical resistance, electrical insulation, high temperature resistance and adhesion. Since chlorine atoms are introduced into the molecular structure of the material, it has excellent properties that natural rubber does not have. These properties make it one of the main products in different fields such as coatings, plasticizers, cables, fireproof materials, adhesives, sealants, etc., and it is a very important industrial raw material.

First of all, Chlorinated Rubber is widely used in the field of coatings. Due to its excellent chemical resistance, weather resistance and adhesion, it is very popular in the preparation of anti-corrosion coatings. Chlorinated Rubber-based coatings are widely used in coating applications for buildings and infrastructure such as construction, chemical industry, shipbuilding, and road markings. It can effectively protect the substrate from corrosion in the external environment, especially for buildings with harsh climatic conditions.

In addition, chlorinated rubber paint is widely used in the anti-corrosion of chemical plants, chemical storage tanks and other projects due to its acid and alkali resistance and solvent resistance, which prolongs the service life of equipment and pipelines. For the shipbuilding industry, hull anticorrosion has excellent seawater corrosion resistance and has become an important application material for chlorinated rubber paint. It can effectively improve the visibility and durability of traffic signs and ensure long-term safety performance.

It is equally important in the field of coatings and cable industry applications. Excellent electrical insulation, good thermal stability and weather resistance make Chlorinated Rubber one of the main manufacturing materials for cables. Since Chlorinated Rubber is both the outer sheath of the cable and the insulating layer, it can truly isolate the cable from the environment, thereby ensuring the safety and stability of power supply. Excellent thermal stability ensures that it can maintain good performance even at high temperatures that are unique to most industrial environments. In addition, it also has strong UV resistance and is suitable for most industrial environments, ensuring that the service life of cables and all electrical machinery is extended.

Chlorinated Rubber is widely used in the preparation of various flame retardant coatings and fire-resistant cables due to its good flame retardant properties. In flame retardant coatings, coatings containing Chlorinated Rubber coatings can well improve the fire safety of buildings, vehicles and other places. Especially in areas with extremely high fire risks such as subways, airports, ships and multi-storey buildings, its coating may be able to prevent the rapid spread of fire and provide potential escape opportunities. At the same time, the sheath material of the fire-resistant cable can prevent combustion and continue to spread rapidly during the cable combustion process, thereby ensuring the normal operation of the power system when it catches fire.

In addition, Chlorinated Rubber is also widely used in the field of adhesives and sealants. Good bonding properties make it the main component of most adhesives. It can be firmly bonded to a range of substrates such as metals, plastics and wood, so it is widely used in bonding needs in various industries such as automobiles, construction and electronic equipment. It can also be used as a sealant to seal pipes, machinery and automobiles, etc. to ensure that they do not leak during operation; this ensures long-term and effective sealing.

1. Stable performance

In fact, chlorinated rubber has excellent weather resistance. It can work stably for a long time under extreme climatic conditions. Even under strong ultraviolet radiation, high temperature, low temperature or humid environment, its physical properties can still be maintained; therefore, it is not easy to age or degrade. In application, it is especially seen in examples such as construction and ships that actually demonstrate its durable performance against the environment.

2. Strong adhesion

Chlorinated rubber has strong adhesion and good contact with the surface of various materials (metal, concrete, wood, plastic, etc.). This feature makes it widely used in the manufacture of coatings, adhesives and sealant products. Whether in industrial equipment, building materials or electrical equipment, it can provide reliable bonding and sealing performance. Good electrical insulation.

3. Electrical insulation

Chlorinated rubber has good electrical insulation, which can effectively resist the leakage of current and ensure the safe operation of power facilities. It is mainly used for the insulation and sheath layer of power cables, and can maintain the electrical properties of cables under various climatic conditions, among which the electrical insulation performance is particularly important under humid and corrosive conditions.

4. Flame retardant properties

Chlorinated rubber has good flame retardant properties. Under extreme temperature or fire conditions, the paint film can inhibit the further spread of flames, that is, the material has a higher ignition point and a lower melting point, and can form a protective layer in the event of a fire to slow down the spread of the fire. Therefore, chlorinated rubber is widely used in fire-retardant coatings and flame-retardant cable plastics, which can improve the fire resistance of buildings, automobiles, power stations, etc.

5. Viscosity and elasticity can be changed as needed

In the application of coatings, adhesives, sealants and other fields, different physical properties can be obtained by adjusting the molecular structure and processing technology according to the formulation requirements. It can achieve good results in both high-elasticity specific demand products (such as sealants) and low-viscosity specific demand products (such as coatings).

Contact Us

Product Package picture:

Related References:

chemicalbook-Chlorinated Rubber

Chlorinated Rubber Manufacturer

Contact Us

As an experienced Chlorinated Rubber manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Chlorinated RubberCAS 9006-03-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.