Bisphenol AF CAS 1478-61-1

Free Sample Bisphenol AF CAS 1478-61-1

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Bisphenol AF

CAS: 1478-61-1

MOQ: 1KG

Directory Guidance on Bisphenol AF

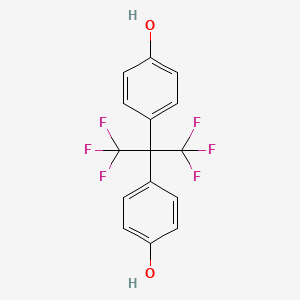

Chemical Structure

Basic Info:

| Melting Point | 160-163 °C(lit.) |

| Boiling Point | 400°C |

| Density | 1.3837 (estimate) |

| Vapor Pressure | 0Pa at 20℃ |

| Fp | >100°C |

Bisphenol AF Introduction:

Bisphenol AF is an important organic chemical raw material. Its chemical name is 4-methylene bis (2-methylphenol), the molecular formula is C16H14O2, and the molecular weight is 234.28. From the appearance, it is usually colorless to light yellow crystals or powder. It is relatively stable at normal temperature and pressure, but it will present different physical states and chemical activities with changes in temperature and environmental factors. As an important fluorine-containing intermediate, Bisphenol AF plays an irreplaceable role in fields such as high-end polymer materials, electronic packaging, and optical coatings.

Bisphenol AF can be produced using hexafluoroacetone and phenol as raw materials, then generated through nucleophilic substitution under acidic catalyst action via nucleophilic substitution reaction. Although its production process is generally straightforward, purification procedures have high requirements in terms of corrosion resistance requirements for equipment corrosion resistance. Due to its strong electronegativity and small radius fluorine atoms, intermolecular force increases significantly which is demonstrated by melting points reaching 162-164; low solubility requires polar solvents such as dimethylformamide or hexamethylphosphoramide before use!

Analysis of its crystal structure shows that fluorine atoms exerting their steric hindering effect leads to a specific orientation for its molecular configuration in Bisphenol AF molecules, leading to rigid orientations within their molecular configuration and increasing both heat distortion temperature and creep resistance. Chemical stability is enhanced due to fluorine substituents on its benzene rings which reduce electron cloud density, making this compound significantly resistant to acids, bases, and oxidants than its conventional equivalent – bisphenol A.

Thermogravimetric analysis indicates that the initial decomposition temperature of Bisphenol AF exceeds 400 ° C in a nitrogen atmosphere. This characteristic lays the foundation for its application in high-temperature environments. It is notable that its ecotoxicity research has attracted much attention in recent years. The existing data indicate that the metabolic pathways of Bisphenol AF in organisms are different from those of bisphenol A, and its persistence in the environment is prolonged due to the fluorinated structure. This has prompted the academic community to continuously carry out research on its environmental fate and toxicological mechanism.

Nature and Specifications:

| Item | Specification |

| Product Name | Bisphenol AF |

| CAS No. | 1478-61-1 |

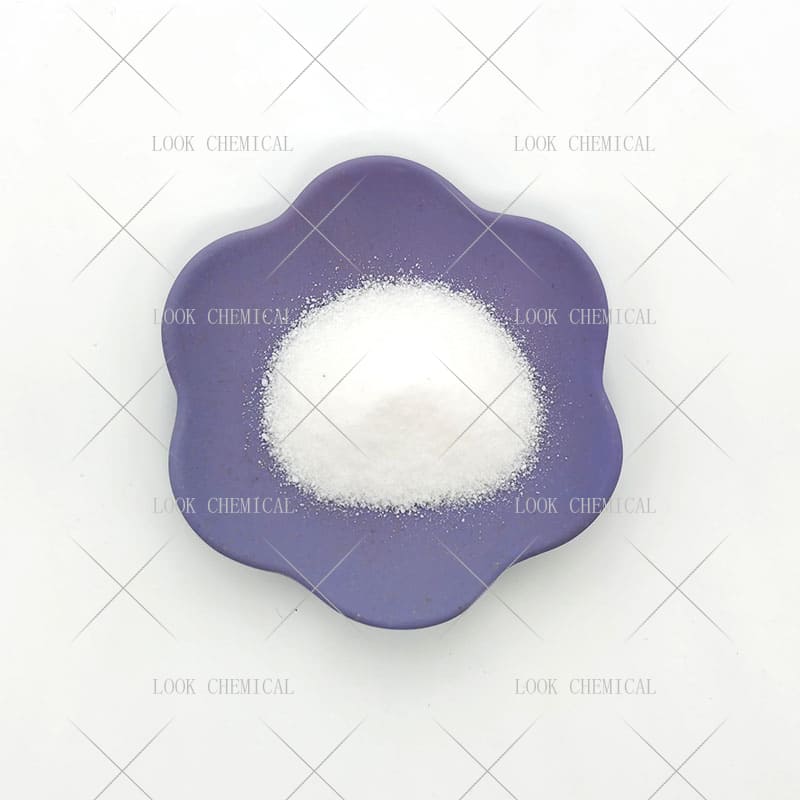

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| pka | 8.74±0.10(Predicted) |

| Form | Powder |

| Color | White to Pale Beige |

| Water Solubility | Insoluble in Water. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Bisphenol AF

Bisphenol AF has extremely wide applications in the field of epoxy resins. Epoxy resin is an important type of polymer material, featuring excellent mechanical properties, electrical insulation performance and chemical stability, among other advantages. As one of the important raw materials of epoxy resin, it can react with compounds such as epichlorohydrin to generate Bisphenol AF type epoxy resin. Compared with the traditional bisphenol A type epoxy resin, this epoxy resin has significant improvements in heat resistance, chemical resistance and mechanical strength.

Bisphenol AF has demonstrated outstanding potential in polycarbonate applications as an engineering plastic, boasting excellent transparency, impact resistance and dimensional stability. Polycarbonate synthesized from Bisphenol AF features higher glass transition temperature as well as better heat and UV resistance – this makes a difference for fields with stringent material performance requirements such as aerospace and automotive industries, where transparent components must perform under conditions such as high temperatures and UV radiation exposure while attenuating performance decline with ageing material.

Electronic packaging materials are another important application direction of Bisphenol AF. As the chip manufacturing process enters the nanoscale, the compatibility of the thermal expansion coefficient of packaging materials has become a key factor determining the lifespan of devices. The linear expansion coefficient of Bisphenol AF-based resin can be regulated to 3.2×10^-6/℃, which is similar to that of silicon chips, while maintaining a thermal conductivity of more than 3.0W/(m·K), making it the preferred material for advanced flip-chip packaging.

In the field of optoelectronics, the transparent film prepared from its derivatives has an ultra-low refractive index of 1.38 and excellent weather resistance, and has been successfully used in anti-reflective coatings for high-precision optical sensors. It is particularly noteworthy that the hybrid material generated by the reaction of Bisphenol AF and a specific silane coupling agent shows good bending durability in the field of flexible display substrates, and can still maintain more than 95% of the initial performance after a million bending tests.

In addition to the fields of epoxy resin and polycarbonate, Bisphenol AF also holds an important position in the production of phenolic resin. Phenolic resin is a thermosetting resin with a long history, featuring excellent heat resistance, flame retardancy and electrical insulation. The introduction of Bisphenol AF can improve the performance of phenolic resin, making it have higher strength and better chemical corrosion resistance. In the field of building materials, modified phenolic resin can be used to produce thermal insulation materials and fireproof boards, etc., which enhances the safety of buildings and energy utilization efficiency.

In addition, Bisphenol AF is gradually emerging in some emerging fields. For example, in the field of optical materials, using its special chemical structure and properties, optical resins with high refractive index, low dispersion and other characteristics can be developed for the manufacture of high-end optical lenses, optical fibers and other products. In the field of composite materials, Bisphenol AF can be compounded with reinforcing materials such as carbon fiber and glass fiber to prepare high-performance composite materials with excellent performance, which are used in sports goods, new energy vehicles and other fields to provide support for the lightweight and high performance of products.

The Advantages Of Bisphenol AF

From the perspective of product performance advantages, the core competitiveness of Bisphenol AF lies in the comprehensive performance improvement brought about by its unique fluorinated structure. Compared with traditional bisphenol A, its dielectric constant is reduced by about 40%, and its volume resistivity is increased by two orders of magnitude, which gives it an absolute advantage in the field of high-frequency and high-speed electronic circuit substrates.

In terms of thermodynamic properties, the introduction of fluorine-containing groups increases the thermal decomposition temperature of the material by more than 150°C, and the temperature of thermal weight loss of 5% reaches 420°C, which fully meets the instantaneous high-temperature protection requirements when aerospace vehicles re-enter the atmosphere. More importantly, the shielding effect of fluorine atoms effectively blocks the erosion of ultraviolet rays on the material body. After 3000 hours of xenon lamp aging test, the yellowing index Δb value of Bisphenol AF-based materials is only 1.2, far lower than the 3.0 required by industry standards.

From the perspective of product development and research, Bisphenol AF has good designability and processability. Its chemical structure is relatively flexible. The performance of the product can be precisely regulated by changing the reaction conditions, adding different additives or copolymerizing with other monomers, etc., to meet the specific needs of different fields. During the processing, Bisphenol AF type materials can be processed through various molding techniques, such as injection molding, extrusion, compression molding, etc., and can be conveniently made into products of various shapes and sizes, which provides convenient conditions for the diversified design and large-scale production of products.

In terms of production cost control, with the continuous improvement of the production process and the gradual expansion of the production scale, the production cost of Bisphenol AF shows a gradually decreasing trend. This enables it to gradually gain a stronger price advantage in the market competition and better meet the market’s demand for high-performance and low-cost materials. Meanwhile, the raw material sources of Bisphenol AF are relatively abundant and stable, providing a solid material basis for its large-scale production and application, which is conducive to ensuring the stable development of related industries.

In terms of environmental protection, Bisphenol AF has lower toxicity compared with traditional similar compounds such as bisphenol A. In recent years, as people’s attention to the environment and health has been continuously increasing, the potential toxicity of bisphenol A has aroused widespread concern and worry. The use of Bisphenol AF can, to A certain extent, reduce the reliance on bisphenol A and lower the environmental risks and harm to human health that may be caused by the leakage or release of bisphenol A into the environment. Meanwhile, during the production and usage processes, the processes and formulations of Bisphenol AF are constantly being optimized to further reduce its negative impact on the environment and make it more in line with the requirements of sustainable development.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Bisphenol AF

Bisphenol AF Manufacturer

Contact Us

As an experienced Bisphenol AF manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Bisphenol AF CAS 1478-61-1 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.