With Factory Best Benzoyl Peroxide Powder CAS 94-36-0

CAS No. 94-36-0

EINECS: 202-327-6

Chemical Name: Benzoyl peroxide

Category: Strong oxidizing agent;Food additives;

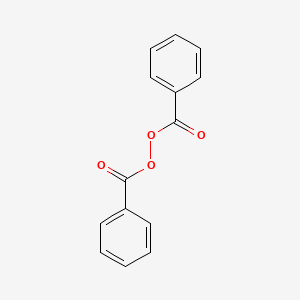

Molecular Formula: C14H10O4

Molecular Weight: 242.23

Purity: 99%min

Brand Name: Look Chemical

Place of Origin: China

Name: Benzoyl peroxide

CAS: 94-36-0

Purity: 99%min

MOQ: 1KG

The Complete Guide of Benzoyl Peroxide Powder

Benzoyl Peroxide Powder Chemical Formula

Basic Info

| CAS No: | 94-36-0 |

| MF: | C14H10O4 |

| Molecular Weight: | 242.23 |

| EINECS: | 202-327-6 |

| Appearance: | White powder |

| Product Name: | Benzoyl Peroxide |

| Other Name: | Benzoyl Peroxide(BPO) |

| Place of Origin: | China |

| Brand: | Look Chemical |

What is Benzoyl Peroxide Powder?

Benzoyl peroxide powder is a white powder, but it also has various commercial specifications, such as paste type (50% of this product with 50% plasticizer), liquid type (75% of this product with 25% water), slightly soluble in ethanol and water, and soluble in other organic reagents. The melting point is 105 ° C and the storage conditions are 2-8 ° C.

Benzoyl peroxide powder has poor stability and is highly flammable. Do not grind or subject to impact or friction. It is incompatible with reducing agents, acids, bases, alcohols, metals, and organic materials. Contact, heating, or friction with flammable materials may cause fire or explosion.

Benzoyl peroxide powder is packaged in polyethylene lined paper bags or fiber drums, or in metal drums lined with polyethylene. Store in a cool, well ventilated independent warehouse made of non combustible materials, with explosion-proof ventilators (explosion-proof holes) installed in a safe direction. It is strictly prohibited to install electrical equipment or heating facilities indoors.

The production site should be ventilated, and protective clothing and safety goggles should be worn during operation to reduce skin contact and eye irritation. In places where powdered or granular Benzoyl Peroxide powder or liquid or paste Benzoyl Peroxide may splash or overflow, protective face shields or masks must also be worn.

Benzoyl Peroxide Powder Uses

Benzoyl Peroxide Powder (BPO) is an organic peroxide with the chemical formula C14H10O4. It is a white or light yellow powder with strong oxidizing properties, commonly used in initiator, bleaching agent, polymerization catalyst and other fields. The specific uses of Benzoyl Peroxide in various fields are as follows:

bleaching agents:

Benzoyl peroxide powder is an efficient bleaching agent widely used in industries such as textiles, papermaking, leather, and wood. In the textile industry, it can be used to bleach natural fibers such as cotton, linen, silk, as well as synthetic fibers. In the paper industry, it can be used to bleach wood pulp and improve the whiteness of paper.

Aggregation catalyst:

Benzoyl peroxide powder is a commonly used free radical polymerization catalyst, widely used in the synthesis of polymer materials. In the fields of plastics, rubber, coatings, adhesives, etc, it can trigger monomer polymerization reactions to improve product performance.

In the field of medicine:

In the field of medicine, Benzoyl Peroxide Powder can be used as a drug carrier for the preparation of sustained-release and targeted drugs. In addition, it can also be used as a disinfectant, preservative。

In the field of pesticides:

Benzoyl peroxide powder can be used as an oxidant in the field of pesticides for the preparation of pesticides. It can improve the insecticidal and bactericidal effects of pesticides, and reduce pesticide residues.

Food industry:

In the food industry, Benzoyl Peroxide Powder can be used as a food additive for fermentation of foods such as flour, bread, and pastries. It can promote dough fermentation, improve the taste and quality of food.

Paint industry:

In the coating industry, benzoyl peroxide powder can be used as a curing agent for the preparation of coatings such as epoxy resin and polyurethane. It can improve the drying speed and adhesion of coatings.

Rubber industry:

In the rubber industry, benzoyl peroxide powder can be used as a vulcanizing agent for the vulcanization process of rubber. It can improve the strength, wear resistance, and aging resistance of rubber.

Other fields:

Benzoyl peroxide powder is also widely used in industries such as cosmetics, detergents, inks, adhesives, etc. In cosmetics, it can be used as an oxidant for the preparation of benzoyl peroxide wash, Benzoyl peroxide face wash, benzoyl peroxide body wash and other products; In detergents, it can be used as a bleaching agent to make benzyl peroxide cleaners and improve washing efficiency.

In short, Benzoyl Peroxide Powder, as an important chemical raw material, has a wide range of applications in various fields. However, due to its strong oxidation, it is necessary to pay attention to safety when using, and avoid contact with flammable and explosive substances.

References

Benzoyl Peroxide – WikiPedia

Benzoyl Peroxide-Chemicalbook

Benzoyl Peroxide Powder for Sale

Applications of Benzoyl Peroxide Powder

Benzoyl peroxide powder (BPO) is an organic peroxide with strong oxidizing properties, commonly used in initiators, bleaching agents, polymerization catalysts, and other fields. The specific uses of Benzoyl Peroxide in various fields are as follows:

The role of benzoyl peroxide powder (BPO) as an initiator in the adhesive industry is mainly reflected in the following aspects:

1.Initiation of polymerization reaction:

Benzoyl peroxide powder is a strong oxidant that can decompose under appropriate conditions to produce free radicals. In the production process of adhesives, BPO is added to monomers containing unsaturated bonds, such as acrylic esters, vinyl esters, styrene, etc. When BPO decomposes, free radicals are released, which can trigger the polymerization reaction of unsaturated bonds in monomer molecules, thereby forming a polymer network.

2.Control aggregation speed:

By adjusting the dosage and addition time of benzoyl peroxide powder, the rate of polymerization reaction can be controlled. In the adhesive industry, an appropriate polymerization rate is crucial to ensure the quality of the adhesive. The decomposition rate of BPO and the generation rate of free radicals can be precisely controlled to adapt to different adhesive formulations and production process requirements.

3.Improve the performance of adhesives:

The polymerization reaction initiated by benzoyl peroxide powder helps to improve the physical and chemical properties of adhesives. For example, polymerization reactions can enhance the adhesive strength, heat resistance, chemical resistance, and durability of adhesives. These performance improvements make adhesives more reliable and effective in various applications.

4.Improve the fluidity of adhesives:

In the preparation process of adhesives, the free radicals generated by the decomposition of Benzoyl Peroxide Powder can promote the rapid polymerization of monomers, thereby improving the fluidity of the adhesive. This helps to improve the uniformity of the adhesive during coating and application, reducing bubbles and defects.

5.Reduce side reactions:

The decomposition products of Benzoyl Peroxide Powder are mainly free radicals, which directly participate in the chain growth process in the polymerization reaction, reducing the occurrence of side reactions. For example, chain transfer reactions and cross-linking reactions that compete with free radicals are reduced, thereby improving the quality of the adhesive.

6.Adapt to different curing conditions:

Benzoyl peroxide powder can function under different curing conditions, including thermal curing, UV curing, and radiation curing. In thermosetting adhesives, BPO decomposes upon heating; In UV curable adhesives, BPO decomposes under UV irradiation; In radiation cured adhesives, BPO decomposes under gamma ray or electron beam irradiation.

7.Security:

Although benzoyl peroxide powder has oxidizing properties, its safety can be controlled when used under appropriate conditions. In the adhesive industry, adding stabilizers and selecting appropriate packaging methods can reduce the decomposition of BPO and improve product safety.

In summary, Benzoyl Peroxide Powder, as an initiator in the adhesive industry, plays a crucial role in initiating polymerization reactions, controlling polymerization rates, improving adhesive properties, improving flowability, reducing side reactions, adapting to different curing conditions, and enhancing safety.

Benzoyl peroxide powder (BPO) is an efficient bleaching agent, and its mechanism of action is mainly based on its strong oxidizing properties. The following are the specific functions of benzoyl peroxide as a bleaching agent:

1. Oxidative decomposition of colored substances:

Benzoyl peroxide powder decomposes in water to produce hydrogen peroxide (H2O2) and benzoic acid (C6H5COOH). Hydrogen peroxide is a strong oxidant that can oxidize and decompose chromophores in organic pigment molecules, causing structural changes and resulting in color loss.

2. Bleach mechanism:

Redox reaction: Benzoyl peroxide powder destroys the structure of pigment molecules through redox reactions, turning them into colorless or light colored substances. This reaction usually occurs on double bonds, aromatic rings, or heterocycles in pigment molecules.

Photocatalytic effect: Under certain conditions, Benzoyl Peroxide Powder can react with light to produce reactive oxygen species (such as singlet oxygen), which have strong oxidizing ability and can further destroy pigment molecules.

3. Long lasting bleaching effect:

Due to the oxidation effect of Benzoyl Peroxide Powder, the bleaching effect is usually long-lasting. The bleached material is not easily yellowed or faded again.

4. Environmental friendliness:

The by-products generated during the decomposition of Benzoyl Peroxide Powder are mainly water and carbon dioxide, which have a relatively small impact on the environment. Therefore, BPO is considered a relatively environmentally friendly bleaching agent.

In summary, Benzoyl Peroxide Powder, as a bleaching agent, achieves a bleaching effect by decomposing colored substances through its strong oxidizing properties. It has a wide range of applications, long-lasting bleaching effect, and is relatively environmentally friendly, so it has important applications in multiple industries.

Benzoyl peroxide powder (BPO), as a polymerization catalyst, mainly plays a role in free radical polymerization reactions. The following are the specific functions of benzoyl peroxide as a polymerization catalyst:

1. Triggering the generation of free radicals:

Benzoyl peroxide powder is a strong oxidant that decomposes under appropriate conditions (such as heating, light, or mechanical stirring) to produce free radicals. These free radicals are the starting point of polymerization reactions, capable of opening double bonds in monomer molecules and initiating polymerization reactions.

2. Control the polymerization reaction rate:

By adjusting the dosage and addition time of benzoyl peroxide powder, the rate of free radical generation can be controlled, thereby controlling the rate of polymerization reaction. This is crucial for synthesizing polymers with specific properties.

3. Improve aggregation efficiency:

The free radicals generated by the decomposition of benzoyl peroxide powder have high activity and can effectively initiate the polymerization reaction of monomer molecules, thereby improving the polymerization efficiency. This means that under the same reaction conditions, using BPO as a catalyst can yield polymer products faster.

4. Wide applicability:

Benzoyl peroxide powder can be used for the polymerization of various monomers, including but not limited to:

Alkenes: such as ethylene, propylene, butene, etc.

Dienes: such as butadiene, isoprene, etc.

Vinyl compounds: such as styrene, methyl methacrylate, etc.

5. Affects the performance of polymers:

The selection and dosage of benzoyl peroxide powder as a catalyst will affect the final properties of the polymer, such as mechanical strength, transparency, heat resistance, etc. By optimizing the usage conditions of BPO, polymers with specific performance requirements can be synthesized.

In summary, Benzoyl Peroxide Powder, as a polymerization catalyst, has become an indispensable chemical raw material in the synthesis of polymer materials by inducing free radical generation, controlling the polymerization reaction rate, improving polymerization efficiency, affecting the molecular weight distribution and properties of polymers, and its application in various monomer polymerizations.

Learn More

Professional Benzoyl Peroxide Powder Supplier

As a professional chemical supplier, we have ten years of chemical supplier experience, more professional and reliable, 24 hours service. Provide free samples.If you want to know more, please come to consult us.

Service

Pre-Sales Service

* Prompt reply and 24 hours online, professional team to provide best price and high quality product.

* Sample testing support.

* Every batch of products will be tested to ensureits quality.

* The packing also can be according the customers` requirment.

* Any inquiries will be replied within 24 hours.

* We provide Commerical Invoice, Packing List, Bill of loading, COA , Health certificate and Origin certificate. If your markets have any special requirements, let us know.

After-Sales Service

* The fact of logistics information monitoring.

* Any questions about the product can be consulted at any time.

* Product has any problem can return.

1. ≤50kg, Express delivery recommended, usually called as DDU service;

2. ≤500kg, Air shipping recommended, usually called as FOB, CFR, or CIF service;

3. >500kg, sea shipping recommended, usually called as FOB, CFR, or CIF service;

4. For high value products, please select air shipping and express delivery for safe.

Do you accept sample order?

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

What’s your MOQ?

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Is there a discount?

Different quantity has different discount.

How to confirm the product quality before placing orders??

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.- Do you supply product report?Yes. We’ll give you product analysis report before shipping.

Packaging and Shipping of Benzoyl Peroxide Powder