4-Methylmorpholine N-Oxide 7529-22-8

High Quality 4-Methylmorpholine N-Oxide 7529-22-8

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: 4-Methylmorpholine N-Oxide

CAS: 7529-22-8

MOQ: 1KG

Directory Guidance on 4-Methylmorpholine N-Oxide

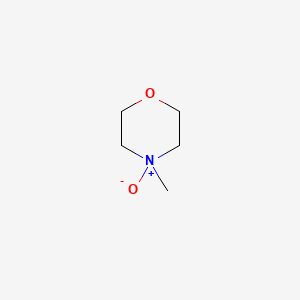

Chemical Structure

Basic Info:

| Melting point | 180-184 °C(lit.) |

| Boiling point | 118-119°C |

| density | 1,14 g/cm3 |

| vapor pressure | 1.41hPa at 20℃ |

| refractive index | n20/D 1.43 |

| Fp | 118-119°C |

Product Introduction:

4-Methylmorpholine N-Oxide, also known as 4-methylmorpholine-N-oxide, is an important organic compound. Its molecular formula is C5H11NO2, molecular weight is 117.15, CAS registration number is 7529-22-8, EINECS registration number is 231-391-8. It is usually in a colorless and transparent liquid state, with a melting point between 180-184°C, a density of 1.130-1.135g/mLat25°C, a refractive index n20/D of 1.420-1.422, and a pH value between 8 and 9. In terms of quality standards, its content is generally 60% (in terms of N-methylmorpholine-N-oxide), the appearance is a colorless and transparent liquid, and the acid value (in terms of HCOOH) is ≤0.01.

In terms of production and synthesis, the preparation methods of 4-Methylmorpholine N-Oxide are diverse. Common synthetic routes include using N-methylmorpholine as the starting material and introducing oxidizing groups through oxidation reactions. This process requires precise control of reaction conditions, such as temperature, pressure, type and amount of catalyst, to ensure high purity and high yield of the product. Different oxidants and reaction systems will affect the quality and performance of the product, so in industrial production, it is crucial to choose a suitable synthesis process.

From the perspective of quality standards and safety, the quality control of 4-Methylmorpholine N-Oxide is strict and must meet specific industry standards. Its purity, acid value and other indicators directly affect its effect in downstream applications. In terms of safety, the compound has a certain chemical stability, but during storage and use, it is still necessary to avoid contact with strong acids, strong bases and other substances to prevent unnecessary chemical reactions. At the same time, operators should take appropriate protective measures, such as wearing protective gloves, goggles, etc., to ensure safety.

In terms of market, the global 4-Methylmorpholine N-Oxide market size will reach RMB 546 million in 2023, and the Chinese market capacity will be RMB 178 million. It is estimated that by 2029, the global market size will grow to 640 million yuan, with a compound annual growth rate of 2.28%. Major global manufacturers include Amines & Plasticizers Limited, BASF, Huntsman, Jiangsu Lianrun Chemical, Sichuan Institute of Fine Chemical, Sigma-Aldrich, Sincere Chemicals, etc. These companies have their own advantages in technology research and development, product quality, market share, etc., and jointly promote the development of the 4-Methylmorpholine N-Oxide industry.

Nature and Specifications:

| Item | Specification |

| Product Name | 4-Methylmorpholine N-Oxide |

| CAS No. | 7529-22-8 |

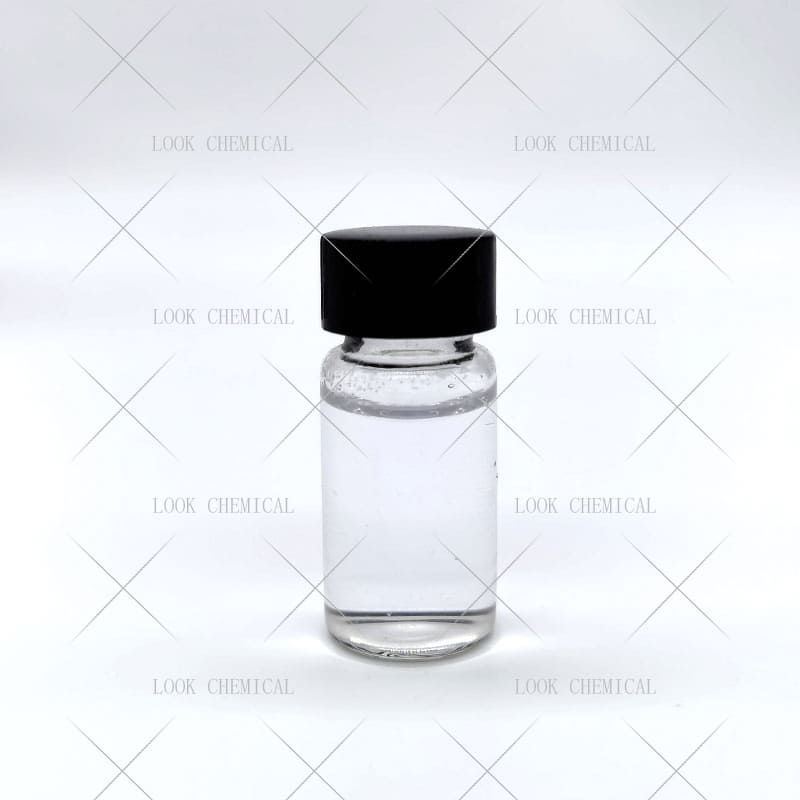

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | 2-8°C |

| solubility | DMSO (Soluble), Methanol (Slightly) |

| pka | 4.93±0.20(Predicted) |

| form | Liquid |

| color | Clear colorless to yellow |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The application as a cellulose solvent is the most revolutionary breakthrough of 4-Methylmorpholine N-Oxide. In the Lyocell fiber production process, its aqueous solution has a solubility of 3-5 times that of the traditional process for natural cellulose, and the dissolution process does not produce chemical derivatives, and the degree of polymerization of cellulose is completely retained. This “physical dissolution” characteristic makes the mechanical properties of the regenerated fiber close to that of natural cotton fiber, while having better dyeability and drape. About 85% of the world’s Lyocell fiber production uses the 4-Methylmorpholine N-Oxide solvent method, which has been recognized by the European Union as the best available technology (BAT). In recent years, breakthroughs in solvent recovery technology have increased its recycling rate to 99.8%, significantly reducing production costs and environmental impact.

In the field of functional material manufacturing, the application of 4-Methylmorpholine N-Oxide is developing in depth. As a precursor of ionic liquids, it can be used to prepare polymer electrolytes with specific conductive properties; in membrane separation technology, 4-Methylmorpholine N-Oxide-based solutions can be spun into nanofiber membranes with uniform pore size distribution, which are used in water treatment and air filtration systems; in the biomedical field, cellulose gels based on it show excellent biocompatibility and are explored for drug sustained release carriers and wound dressings. It is worth noting that the application research of 4-Methylmorpholine N-Oxide in the development of new battery separator materials has entered the pilot stage, and its high thermal stability and electrolyte tolerance are expected to solve the safety bottleneck problem of lithium-ion batteries.

Innovative applications in the field of catalysis are expanding the value boundaries of 4-Methylmorpholine N-Oxide. As a non-metallic catalyst, it shows activity comparable to that of transition metal catalysts in the silylation reaction of ketone compounds, and avoids the problem of heavy metal pollution. In polymer synthesis, it can regulate the pore structure of polyurethane foaming process and prepare functional foam materials with gradient pores. The latest research shows that the electron transfer effect of 4-Methylmorpholine N-Oxide in the photocatalytic system can significantly improve the efficiency of photocatalytic water splitting to produce hydrogen, which opens up a new direction for its application in the field of new energy. With the deepening of the concept of green chemistry, its potential in replacing traditional toxic catalysts is being continuously explored.

Compared with carbon disulfide used in the viscose method, 4-Methylmorpholine N-Oxide dissolution process does not produce toxic gases such as CS₂ and H₂S, and the solvent recovery rate exceeds 99%, which truly realizes clean production. Third-party testing data shows that the COD value of lyocell fiber production wastewater using the 4-Methylmorpholine N-Oxide process is two orders of magnitude lower than that of the traditional process, with significant environmental benefits.

The economic advantage of the product is reflected in the cost control of the entire life cycle. Although the price of 4-Methylmorpholine N-Oxide monomer is higher than that of traditional solvents, its recycling number can reach more than 20 times, and the actual use cost is reduced by 40%-60%. The compatibility of production equipment is also an important consideration-it is non-corrosive to stainless steel reactors, and the equipment maintenance cycle is extended by 3-5 times.

In terms of technical scalability, 4-Methylmorpholine N-Oxide exhibits strong platform compound characteristics. The active oxygen atoms in its molecular structure can be used as functional modification sites. Through chemical modification, a series of derivatives can be obtained, expanding special chemicals such as flame retardants and antistatic agents. The innovative flexibility of the production process is also outstanding: the same production device can produce fiber-grade solvents in the form of 50% aqueous solution through parameter adjustment, and can also prepare 99.5% high-purity crystals to meet the production needs of pharmaceutical intermediates. This flexible production capacity enables enterprises to respond quickly to changes in market demand and increase product added value.

Safety and stability are the key indicators that distinguish 4-Methylmorpholine N-Oxide from similar products. Through crystallization purification technology, the impurity content of organic peroxides can be controlled below 10ppm, greatly reducing the risk of explosion during storage and transportation. Accelerated aging experiments show that the degradation rate of the active ingredient of the sealed 4-Methylmorpholine N-Oxide aqueous solution stored at room temperature for 3 years is less than 0.3%, far exceeding the shelf life of similar oxidants. In terms of operational safety, its LD50 value (rat oral) is >5000mg/kg, which is actually non-toxic. No special anti-toxic facilities are required in the production process, which significantly reduces the company’s safety production investment.

From the perspective of industrial development, the technical barriers of 4-Methylmorpholine N-Oxide have built a sustainable competitive advantage. Its production process involves a number of key technologies such as catalytic oxidation, azeotropic separation, and crystal growth, forming a technology package covering 12 core patents. The special design requirements of production equipment, such as the mass transfer enhancement structure of the oxidation reactor and the gradient temperature control system of the crystallizer, constitute a high entry threshold. The quality control system is an important component of competitive advantage – the ion chromatography detection method established by leading companies can reduce the impurity detection limit to 0.01ppm. This extreme quality control capability ensures the irreplaceable nature of the product in high-end application fields.

Contact Us

Product Package picture:

Related References:

chemicalbook-4-Methylmorpholine N-Oxide

4-Methylmorpholine N-Oxide Manufacturer

Contact Us

As an experienced 4-Methylmorpholine N-Oxide manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As 4-Methylmorpholine N-Oxide CAS 7529-22-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.