1,4-Butanediol Diacrylate CAS 1070-70-8

High Quality 1,4-Butanediol Diacrylate CAS 1070-70-8 with Free Sample

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: 1,4-Butanediol Diacrylate

CAS: 1070-70-8

MOQ: 1KG

Directory Guidance on 1,4-Butanediol Diacrylate

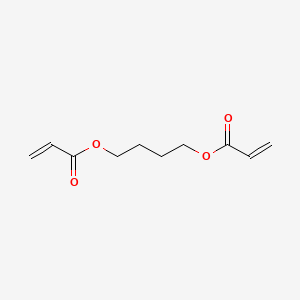

Chemical Structure

Basic Info:

| Melting point | -7°C |

| Boiling point | 83 °C/0.3 mmHg (lit.) |

| density | 1.051 g/mL at 25 °C (lit.) |

| vapor pressure | 0.83 hPa (80 °C) |

| refractive index | n20/D 1.456(lit.) |

| Fp | >230 °F |

Product Introduction:

1,4-Butanediol Diacrylate (BDDA for short) is an important organic compound belonging to the class of acrylates. Its chemical form is C₁₀H₁₄O₄ with a molecular weight of 198.22. The compound is a derivative derived from the reaction of 1, 4-butanediol with acrylic anhydride, which has high reactivity and wide application value.The synthesis of BDDA is mainly achieved through the esterification reaction of 1,4-butanediol and acrylic acid. Acid catalysts (such as p-toluenesulfonic acid) or solid acid catalysis are often used. In the reaction process, an inhibitor (such as methoxyhydroquinone MEHQ) needs to be added to stabilize the product.

In terms of physical properties, 1,4-Butanediol Diacrylate is a colorless to light yellow transparent liquid with a density of about 1.051 g/mL (25℃), a boiling point of 83℃ (0.3 mmHg), a flash point of more than 113℃, and a refractive index of 1.456. Its low viscosity (about 8 cps, 25°C) and immiscibility with water make it compatible with a variety of organic solvents (such as alcohols, esters, and ethers), and easy to disperse evenly in the formulation. The diacrylate group of BDDA makes it dually reactive and can quickly form a three-dimensional cross-linked network through free radical polymerization, which is particularly critical in ultraviolet (UV) or electron beam (EB) curing systems.

From a chemical performance point of view, the high reactivity of 1,4-Butanediol Diacrylate comes from the vinyl (–CH=CH₂) and carbonyl (C=O) structures in the acrylate group. Under the initiation of light or electron beam, these groups quickly participate in the chain growth reaction to form a dense polymer network. Compared with other diacrylates (such as HDDA), the short chain structure of BDDA leads to a higher cross-linking density, which gives the cured material higher rigidity, hardness and chemical resistance. In addition, the molecular design of BDDA balances mechanical strength and processing performance, so that it can not only meet the high durability requirements, but also act as a reactive diluent in the formulation to reduce the viscosity of the system.

In terms of safety, 1,4-Butanediol Diacrylate belongs to corrosive chemicals. Contact with skin or inhalation may cause burns or allergic reactions, and protective equipment must be worn during operation. It must be transported in accordance with the UN 1760 standard (Dangerous goods Class 8), and it is recommended to store at 2-8 ° C away from light to maintain stability. Despite the risks, BDDA’s low volatility and high stability give it a controllable operating window in industrial applications, especially in closed production processes.

Nature and Specifications:

| Item | Specification |

| Product Name | 1,4-Butanediol Diacrylate |

| CAS No. | 1070-70-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | 2-8°C |

| solubility | 16.3g/l |

| form | Liquid |

| Specific Gravity | 1.055-1.105 |

| color | Colorless |

| explosive limit | 1.3-7%(V) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

As a highly active bifunctional monomer, 1,4-Butanediol Diacrylate has shown unique application value in the field of modern chemical industry. The synergistic effect of the two acryloyl groups and the butanediol skeleton in its molecular structure enables it to provide rapid crosslinking ability in the polymerization reaction and give the polymer excellent flexibility and chemical resistance. This performance balance makes it one of the core raw materials in the field of photocurable coatings, functional polymer materials and composite materials.

Innovative applications in the adhesive field have further expanded the market space for 1,4-Butanediol Diacrylate. Added as a modifier to epoxy resin adhesives, BDDA can form an interpenetrating polymer network (IPN) through in-situ polymerization, significantly improving the temperature resistance and impact resistance of the adhesive.

The upgrade and iteration of ion exchange resins is inseparable from the chemical contribution of 1,4-Butanediol Diacrylate. The traditional styrene-divinylbenzene system has problems of pore blockage and resin embrittlement when treating high-salinity wastewater. After 1,4-Butanediol Diacrylate is introduced as a cross-linking monomer, the three-dimensional network structure formed has better swelling stability and selective adsorption capacity. This new resin has shown significant advantages in the fields of rare earth element separation and deep treatment of pharmaceutical wastewater, especially in terms of dynamic adsorption capacity and regeneration cycle life, which is more than 30% higher than traditional products.

The innovative application of leather finishing agents demonstrates the environmental protection potential of 1,4-Butanediol Diacrylate. Traditional leather coating agents are controversial because they contain formaldehyde releasers, while 1,4-Butanediol Diacrylate has developed an ecological coating technology with zero formaldehyde emissions by grafting and copolymerizing with natural polyphenols.

The breakthrough application in the field of optical materials has further consolidated the position of 1,4-Butanediol Diacrylate. In the production of optical fiber preform rods, BDDA as a comonomer can accurately control the refractive index gradient distribution of the polymer while suppressing light scattering loss. In organic light-emitting diode (OLED) encapsulation materials, 1,4-Butanediol Diacrylate is compounded with phosphorus-containing inhibitors to effectively block the water and oxygen penetration path and extend the service life of the device. This material combination has been used in high-end display fields such as folding screen mobile phones and in-vehicle display systems.

Innovative applications in the field of composite materials have opened up new growth space for 1,4-Butanediol Diacrylate. In carbon fiber reinforced thermoplastics (CFRTP), BDDA forms an interface reinforcement layer through in-situ polymerization, which significantly improves the interface shear strength between the fiber and the matrix.

In terms of processing performance, the low viscosity (8 cps) of 1,4-Butanediol Diacrylate enables it to have both dilution and crosslinking functions in the formulation. Compared with high-viscosity monomers (such as some epoxy acrylates), BDDA can reduce the viscosity of the system by more than 50%, thereby improving the leveling, substrate wetting and spray atomization effect of coatings or inks. Its fast curing characteristics (curing time is less than 1 second at 100 mJ/cm² UV energy) greatly improve production efficiency, and it is particularly suitable for high-speed assembly line operations such as coil coating and continuous printing.

In terms of chemical resistance, the cross-linked network of 1,4-Butanediol Diacrylate after curing shows excellent stability to acids, alkalis, salt spray, grease, etc. The ester group and carbon chain structure in its molecules also give the material excellent hydrolysis resistance, and it can still maintain mechanical properties in a humid and hot environment (85℃/85% RH), which is suitable for harsh scenes such as marine engineering and outdoor electronic equipment. In addition, BDDA’s high stability to ultraviolet rays makes it less likely to yellow under long-term sunlight, maintaining the appearance performance of the material.

From the perspective of sustainable development, the environmental advantages of 1,4-Butanediol Diacrylate are becoming increasingly prominent. Its UV/EB curing process does not require solvents, and its energy consumption is 60%-70% lower than that of traditional thermal curing, which is in line with the trend of low-carbon manufacturing. With the industrialization of bio-based 1,4-butanediol (such as preparation through glucose fermentation), the raw material renewability of BDDA is further improved, and the carbon footprint is reduced by about 40%, which helps the green transformation of the chemical industry.

In terms of economy, the efficient cross-linking properties of 1,4-Butanediol Diacrylate can reduce the amount of monomer added in the formula (usually accounting for 5%-15%) and reduce the cost of raw materials. Its wide application compatibility (such as blending with various oligomers such as polyurethane and epoxy resin) reduces the investment in special equipment and is suitable for flexible production modes of multiple varieties and small batches. From the market trend, the annual growth rate of global UV curing materials is stable at 6%-8%. As a core monomer, BDDA will continue to benefit from the expansion of downstream industries such as automobiles, electronics, and packaging. It is expected that the market size will exceed US$1.5 billion in 2030.

Contact Us

Product Package picture:

Related References:

chemicalbook-1,4-Butanediol Diacrylate

1,4-Butanediol Diacrylate Manufacturer

Contact Us

As an experienced 1,4-Butanediol Diacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As 1,4-Butanediol Diacrylate CAS 1070-70-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.