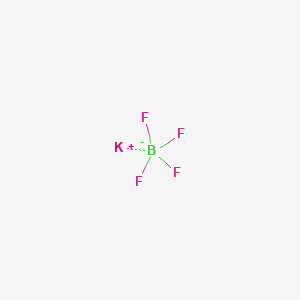

Potassium Tetrafluoroborate CAS 14075-53-7

Factory wholesale Potassium Tetrafluoroborate CAS 14075-53-7

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Potassium Tetrafluoroborate

CAS: 14075-53-7

MOQ: 1KG

Directory Guidance on Potassium Tetrafluoroborate

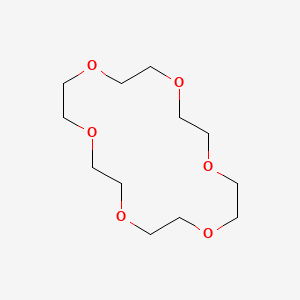

Chemical Structure

Basic Info:

| Melting Point | 530 °C(lit.) |

| Density | 2.505 g/mL at 25 °C(lit.) |

| Refractive Index | 1.3245 |

| Storage Temp. | Sealed in dry,Room Temperature |

| Solubility | Slightly Soluble in Ethanol |

| Form | Micro-Crystalline Powder |

Potassium Tetrafluoroborate Introduction:

Potassium Tetrafluoroborate (KBF4) is an inorganic compound composed of potassium, boron and fluorine that typically appears as white crystals or powder-like solid. It belongs to the orthorhombic crystal system. The molecular weight is approximately 125.91 g/mol and its density approximately 2.5 g/cm3. This compound exhibits excellent chemical stability at room temperature. Although slightly soluble in cold water, its solubility increases significantly with increasing temperatures to reach approximately 25 g/100 mL in boiling water. At temperatures higher than 530 deg C, potassium fluoride can decompose into potassium fluoride and boron trifluoride gas. Potassium Tetrafluoroborate can be produced through reacting hydrofluoric acid with boric acid to produce fluoroboric acid, and neutralizing it using either potassium hydroxide or potassium carbonate in a one-step process. A two-step approach may also be utilized, though to maximize yield it should be noted that hydrofluoric acid use must be carefully managed during production to minimize equipment corrosion risks and safeguard personnel safety risks.

Potassium Tetrafluoroborate can decompose in acidic environments and interacts with strong acids to release highly toxic hydrogen fluoride gas, so care must be taken to avoid contact with acidic substances during storage and use. Fluorosilicic acid exhibits limited corrosion to silicate materials like glass and ceramic, unlike some other fluorides whose corrosion levels can be more easily managed. Potassium Tetrafluoroborate can remain stable in dry environments for some time; however, in humid ones it may undergo slow hydrolysis to produce trace amounts of hydrogen fluoride and boric acid. Due to its unique fluoroborate ion structure (BF 4-), Potassium Tetrafluoroborate’s unique coordination ability gives it special value in industrial applications.

Historical background aside, industrial production of Potassium Tetrafluoroborate began during the mid-20th century due to an explosion in electroplating industry growth and subsequent challenges associated with traditional fluorides in terms of performance limitations. Potassium Tetrafluoroborate has recently come to our attention due to its superior conductivity and chelating ability. After years of technological optimization, modern production processes have reached stable production with high purity (>99.5%) and minimal impurity content. At present, major producing countries include China, Germany and the US; among these nations China stands out as being the top producer and exporter of Potassium Tetrafluoroborate with its comprehensive fluorine chemical industry chain.

Nature and Specifications:

| Item | Specification |

| Product Name | Potassium Tetrafluoroborate |

| CAS No. | 14075-53-7 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As Your Requirements |

| color | White to light gray |

| Odor | wh. odorless cryst. |

| Water Solubility | 4.4 g/L (20 ºC) |

| Sensitive | Moisture Sensitive |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The Application Situation Of Potassium Tetrafluoroborate

In the metallurgical industry, Potassium Tetrafluoroborate is a recognized high-efficiency flux, and its irreplaceability is widely known. In the aluminum alloy smelting process, adding 0.5-2% Potassium Tetrafluoroborate can significantly reduce the surface tension, so that metal oxide impurities can be precipitated, and a protective slag layer is formed in the copper alloy casting to prevent metal burns, thereby preventing melt inhalation and improving the density of the casting. For this reason, Potassium Tetrafluoroborate is widely used in special steel smelting, because it reduces the content of harmful elements by reducing the content of sodium and phosphorus, and increases the purity of molten steel by more than 30%.

The largest application market for Potassium Tetrafluoroborate is the electroplating industry. In the electroplating solution, fluoroborate itself, as a strong ligand, can form a stable complex with metal ions such as copper, tin, and lead, thereby ensuring uniform coating during the electroplating process. Compared with the traditional cyanide electroplating system, the fluoroborate system has the characteristics of low toxicity, high current efficiency (greater than 95%), and dense coating. In the process of printed circuit board manufacturing, electrolytes based on it can ensure high-precision circuit plating at the micron level, and the surface roughness can be controlled above Ra0.2μm. Potassium Tetrafluoroborate can also increase the bonding strength of gold and silver coatings by about 20%, which will significantly extend the service life of precious metals such as jewelry and electronic connectors.

In the field of chemical catalysis, Potassium Tetrafluoroborate shows unique advantages as a Lewis acid catalyst. In transesterification reactions, it can also complete the reaction in 40% of the time and achieve more than 98% product selectivity. This catalytic property stems from its strong electron acceptor properties, that is, the activation of reactant molecules by fluoroborate ions. In polymer synthesis, Potassium Tetrafluoroborate, as an anionic initiator, can prepare high-regularity polymers with a molecular weight distribution index of less than 1.2, thereby meeting the production requirements of special engineering plastics.

Potassium Tetrafluoroborate is used as a high-performance flux in glaze formulations in the ceramic industry. Its firing temperature is between 1200-1350℃, which can reduce the melting temperature of the glaze by 80-100℃, thereby promoting the formation of the glass phase and inhibiting the excessive growth of quartz crystals. This increases the glossiness of the glaze of ceramic products by 2-3 levels and reduces the water absorption to less than 0.5%. In special ceramic applications, the addition of this product can adjust the dielectric constant of the material to accurately vary within the range of 3.5 to 4.5, which can usually meet the performance requirements of high-frequency electronic components. Potassium Tetrafluoroborate is used as a nucleating agent in the production of microcrystalline glass to control the grain size to about 50-200 nanometers, thereby significantly improving the mechanical properties of the material.

In the nuclear industry, the neutron absorption properties of Potassium Tetrafluoroborate have important applications. The capture cross section of the boron-10 isotope for thermal neutrons is as high as 3837 barns, which makes boron-containing materials play a key role in nuclear reactor control systems. Due to its high thermal stability and chemical inertness, it has been used as a poison additive in liquid metal cooled reactors, which can effectively regulate the reactor power. In the process of nuclear waste treatment, the use of Potassium Tetrafluoroborate glass solids can stabilize radionuclides for thousands of years, and its leaching rate is less than 1×10⁻⁶g/(m²·d), which is much better than the traditional borosilicate glass system.

The Advantages Of Potassium Tetrafluoroborate

An analysis of product performance advantages revealed that Potassium Tetrafluoroborate’s chemical stability is its core competitive advantage. Under ideal storage conditions, product shelf life has been extended to over 36 months and moisture absorption rate remains below 0.3%/year due to compact crystal structures and strong electronegativity protection of fluoride ions. Potassium Tetrafluoroborate stands out from other fluorides (like NaBF4) with its increased decomposition temperature in high temperature/high humidity environments compared to others ( like NaBF4) by having increased storage stability over 50degC; this ensures excellent transportation/warehousing security as well as providing assurance for large-scale industrial applications.

Potassium Tetrafluoroborate stands out for its versatility, meeting multiple functional requirements at once such as metallurgical fluxing, electroplating complexation, ceramic glazing and neutron absorption. Cross-field applications of inorganic compounds are relatively uncommon. Potassium Tetrafluoroborate’s unique “one dose, multiple functions” feature makes production simpler while decreasing auxiliary additive use by more than 30% and cutting costs by over 15% overall. When applied in electroplating applications, Potassium Tetrafluoroborate acts not only as the main salt but can also buffer pH levels of bath solutions and inhibit hydrogen embrittlement occurrence. These benefits allow electroplaters to decrease costs overall by over 15% while streamlining production process as a whole.

Potassium Tetrafluoroborate offers excellent economic returns when used to refine aluminum alloy. When added at 1.5kg per ton of aluminum for refining purposes, Potassium Tetrafluoroborate increases yield by 2.3%. Potassium Tetrafluoroborate systems in electroplating have proven themselves highly cost-effective over the years, saving 25-30% of electricity compared to cyanide systems, and reducing waste liquid treatment costs by 40%.

Potassium Tetrafluoroborate has demonstrated excellent safety performance through technological innovation. All risks have been effectively controlled. Microencapsulated Potassium Tetrafluoroborate product can raise the lower limit concentration for dust explosion to 500g/m3; more than three times higher than regular powder products. Double-layer PE bags containing desiccant help ensure moisture content in products stays below 0.5% and effectively prevent agglomeration and degradation during packaging processes. Transport of Potassium Tetrafluoroborate falls under general cargo chemical and does not require special hazardous chemical transportation qualifications, greatly reducing logistics costs and storage restrictions. Thanks to these safety improvements, Potassium Tetrafluoroborate’s operational risk level has decreased from Class B to Class D thus broadening its application range.

Potassium Tetrafluoroborate meets all of the stringent environmental performance requirements set forth by global chemical management systems. According to EU REACH regulation, Potassium Tetrafluoroborate has been listed as a substance of low concern (NLP). US EPA classified its toxicity rating as Category IV (or non-toxic). Comparative to cyanide electroplating systems, fluoroborate electroplating processes reduce wastewater treatment difficulty by 60% while heavy metal emissions decrease by 85-85%. Potassium Tetrafluoroborate can significantly lower firing temperatures and CO2 emissions in ceramic firing processes by cutting temperatures by about 20% and emissions by about 22% respectively, meeting environmental criteria such as RoHS and REACH certification requirements to support green manufacturing development trends.

Contact Us

Product Package picture:

Related References:

Chemicalbook-Potassium Tetrafluoroborate

Potassium Tetrafluoroborate Manufacturer

Contact Us

As an experienced Potassium Tetrafluoroborate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Potassium Tetrafluoroborate CAS 14075-53-7 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.