Tris(2-Chloroethyl) Phosphate CAS 115-96-8

Tris(2-Chloroethyl) Phosphate CAS 115-96-8With Free Sample

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Tris(2-Chloroethyl) Phosphate

CAS: 115-96-8

MOQ: 1KG

Directory Guidance on Tris(2-Chloroethyl) Phosphate

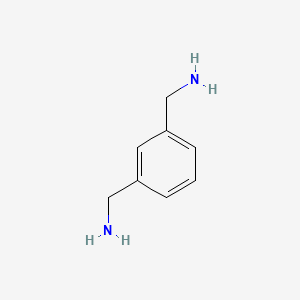

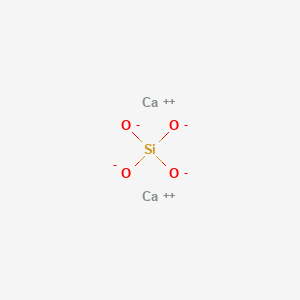

Chemical Structure

Basic Info:

| Melting point | -51 °C |

| Boiling point | 192 °C/10 mmHg (lit.) |

| density | 1.39 g/mL at 25 °C (lit.) |

| vapor pressure | <10 mm Hg ( 25 °C) |

| refractive index | n20/D 1.472(lit.) |

| Fp | 450 °F |

Product Introduction:

Tris(2-Chloroethyl) Phosphate (TCEP for short) is a chlorine-containing organic phosphate compound with a molecular formula of C6H12Cl3O4P and a molecular weight of 285.49 g/mol. From the chemical structure point of view, the substance is composed of a phosphate group connected to three 2-chloroethyl functional groups. This unique molecular design makes it have the characteristics of both polar groups and hydrophobic groups.

It is a colorless or light yellow transparent liquid at room temperature, with a density of about 1.39 g/cm³, a boiling point of about 330°C, and a low vapor pressure (about 0.001 mmHg at 25°C). These physical properties determine its stability and operability in industrial applications. It is worth noting that Tris(2-Chloroethyl) Phosphate has a low solubility in water (about 0.7 g/L at 20°C), but is easily soluble in most organic solvents. This solubility characteristic provides the basis for its compatibility in different systems.

From a chemical synthesis perspective, Tris (2-Chloroethyl) Phosphate is mainly prepared through the addition reaction of phosphorus oxychloride with ethylene oxide. Strict control of temperature, pressure, and catalyst dosage is required during the reaction process to ensure product purity and yield. Modern industrial production typically utilizes continuous production processes which include multi-stage distillation and molecular sieve adsorption technology in order to remove impurities; final purity levels typically surpass 98%.

Animal experiments have demonstrated Tris(2-Chloroethyl) Phosphate to have moderate acute and chronic toxicity; its oral lethal dose in rats ranges between 400-800 mg/kg; chronic exposure may affect both nervous system function and reproduction, according to studies done on animals. As per US Environmental Protection Agency classification as potential carcinogen and EU REACH regulation setting strict limits, environmental behavior studies indicate its half-life in soil ranges between 30-60 days while activated sludge water treatment plants effectively adsorbed and degraded its bioaccumulation effects should be closely monitored as bioaccumulation effects need be closely managed for safety reasons.

Nature and Specifications:

| Item | Specification |

| Product Name | Tris(2-Chloroethyl) Phosphate |

| CAS No. | 115-96-8 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | 2-8°C |

| solubility | H2O: soluble7.82g/L |

| form | Liquid |

| color | Clear colorless |

| Water Solubility | 7 g/L (20 ºC) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

As a representative substance in the field of flame retardants, Tris(2-Chloroethyl) Phosphate has been industrially applied since the 1970s, and was initially used mainly for fireproofing of polyurethane foam plastics. With the advancement of polymer material technology, its application range has expanded to engineering plastics, synthetic rubber, textile coatings and other fields.

Tris (2-Chloroethyl) Phosphate can significantly enhance flame retardant grades of polyvinyl chloride (PVC) products while simultaneously serving as an auxiliary plasticizer to increase processing flowability and processing flowability. In recent years, demand for Tris (2-Chloroethyl) Phosphate in electronics and electrical industries has seen its demand greatly increase – it’s used to modify epoxy resin packaging materials for circuit boards with flame retardants or insulation coatings and insulation coatings for circuit boards. According to industry statistics, global production capacity exceeded 100000 tons in China alone while Asia consumed over 65% of global consumption!

Tris (2-Chloroethyl) Phosphate stands out in the field of specialty chemicals for its distinct use as an extreme pressure anti-wear additive for hydraulic and lubricating oils, where its chlorine element forms protective ferric chloride films under high-temperature friction conditions. Furthermore, oil exploration companies employ it in drilling fluid formulations with its flame retardancy and thermal stability properties to safeguard underground operations.

In the field of fine chemicals, Tris (2-Chloroethyl) Phosphate is an important intermediate for the synthesis of certain quaternary ammonium salt surfactants, especially in the preparation of zwitterionic surfactants, which plays an irreplaceable role. In addition, in laboratory research, this compound is often used as an internal standard substance for nuclear magnetic resonance spectroscopy analysis, and its stable chemical properties and characteristic spectral peaks provide convenience for scientific research work.

In terms of flame retardancy, the outstanding performance of Tris (2-Chloroethyl) Phosphate is attributed to its dual action mechanism. In terms of gas-phase flame retardancy, the chlorine free radicals released by thermal decomposition can effectively capture the active free radicals in the combustion chain reaction; In terms of condensed phase flame retardancy, the decomposed phosphoric acid promotes the formation of a carbon layer, isolating heat and oxygen transfer.

Compared with traditional bromine based flame retardants, Tris (2-Chloroethyl) Phosphate has a flame retardant efficiency increase of about 20%, and does not produce carcinogenic polybrominated dibenzodioxins during combustion. Comparative experiments in polyurethane rigid foam show that adding 12% Tris (2-Chloroethyl) Phosphate can achieve UL94 V-0 flame retardant standards, while similar products require an addition amount of over 15%. This high efficiency directly reduces the cost of material modification while minimizing the negative impact of additives on the mechanical properties of the matrix.

From a compatibility perspective, Tris (2-Chloroethyl) Phosphate has better compatibility with the vast majority of polymer materials than other phosphate flame retardants. The test data in ABS resin shows that when the addition amount reaches 20%, the surface glossiness of the material can still be maintained without precipitation or frosting. This excellent compatibility stems from the similar polarity of the chloroethyl group and polymer segments in its molecular structure, allowing flame retardant molecules to be uniformly dispersed within the matrix.

In terms of processing performance, Tris (2-Chloroethyl) Phosphate has a moderate viscosity (about 150 mPa · s at 25 ℃), which will not cause abnormal torque fluctuations in equipment during high-temperature processing such as injection molding and extrusion. The thermal stability test showed that its thermal decomposition starting temperature (determined by TGA method) reached 280 ℃, fully meeting the temperature requirements for the majority of plastic processing.

Environmental friendliness has become the core competitiveness that sets Tris (2-Chloroethyl) Phosphate apart from traditional flame retardants. Although it has inherent biological toxicity, it demonstrates significant advantages in life cycle assessment (LCA): carbon emissions during production are reduced by 40% compared to brominated flame retardants, and wastewater treatment difficulty is reduced by 50%. According to EU eco label certification data, building materials modified with Tris (2-Chloroethyl) Phosphate can reduce VOCs emissions by 30%.

In terms of cost-effectiveness, Tris (2-Chloroethyl) Phosphate exhibits strong market competitiveness. In terms of raw material costs, the production of phosphorus oxychloride and ethylene oxide required are both basic chemical products, and the global supply chain is mature and stable. In terms of process cost, the single ton energy consumption of continuous production equipment is reduced by 25% compared to batch method, and the catalyst service life is extended to over 8000 hours.

The analysis of end-user costs shows that although the unit price of Tris (2-Chloroethyl) Phosphate is higher than some alternatives, its overall cost has decreased by 10-15% due to its low addition amount and low processing loss. The economic assessment report of the American Chemical Society states that using Tris (2-Chloroethyl) Phosphate solution in automotive interior material applications can reduce the cost of a single product by $0.8, while meeting the FMVSS 302 fire protection standard.

The current global Tris (2-Chloroethyl) Phosphate market is showing an accelerating trend of technological iteration, with nanocapsulation technology, microencapsulation modification, and reactive flame retardant development becoming the main innovative directions. A Japanese company has recently launched a nano silica coated Tris (2-Chloroethyl) Phosphate product, which increases the thermal decomposition temperature to 310 ℃ and solves the migration problem.

The microencapsulation technology developed by a South Korean research team enables the addition of Tris(2-Chloroethyl) Phosphate in epoxy resin to be reduced by 40% while still achieving the same flame-retardant effect. These technological advancements not only consolidated the market position of Tris(2-Chloroethyl) Phosphate, but also opened up emerging application fields such as aerospace and new energy batteries for it. According to industry forecasts, the global demand for Tris (2-Chloroethyl) Phosphate will maintain an average annual growth rate of 6-8% in the next five years, especially in the fields of fireproof materials for electric vehicle battery packs and flame retardant coatings for 5G communication equipment.

Contact Us

Product Package picture:

Related References:

chemicalbook-Tris(2-Chloroethyl) Phosphate

Tris(2-Chloroethyl) Phosphate Manufacturer

Contact Us

As an experienced Tris(2-Chloroethyl) Phosphate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Tris(2-Chloroethyl) Phosphate CAS 115-96-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.