Methyltrimethoxysilane CAS 1185-55-3

Factory wholesale Methyltrimethoxysilane CAS 1185-55-3

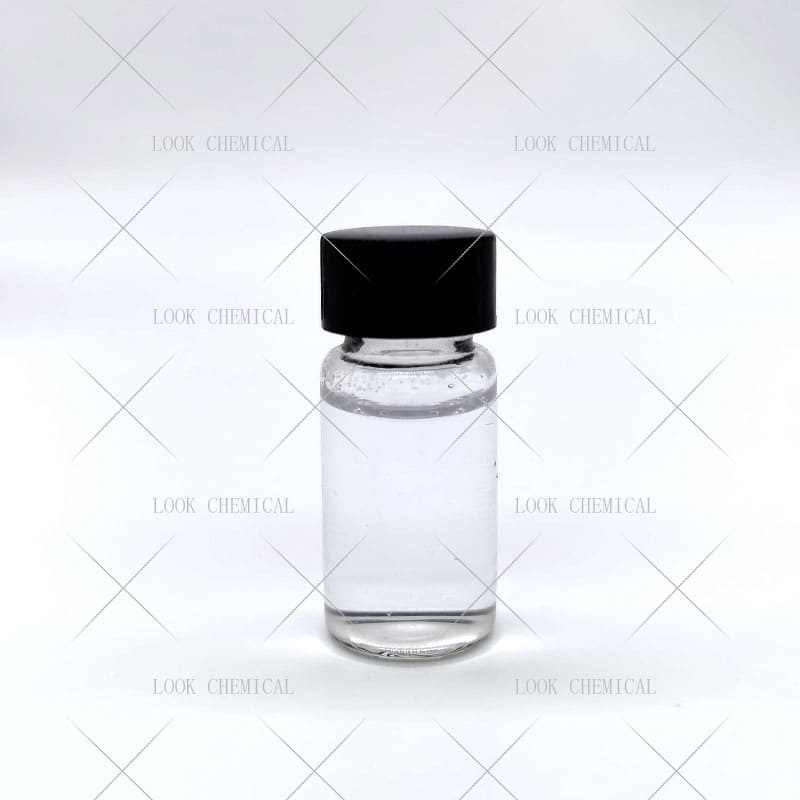

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Methyltrimethoxysilane

CAS: 1185-55-3

MOQ: 1KG

Directory Guidance on Methyltrimethoxysilane

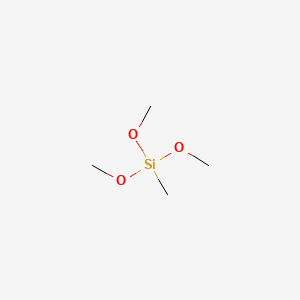

Chemical Structure

Basic Info:

| Melting point | <-70°C |

| Boiling point | 102-104 °C(lit.) |

| density | 0.955 g/mL at 25 °C(lit.) |

| vapor pressure | 2990 hPa (20 °C) |

| refractive index | n20/D 1.371(lit.) |

| Fp | 52 °F |

Product Introduction:

Methyltrimethoxysilane (MTMS for short) is an organosilicon compound with the chemical formula CH3Si(OCH3)3. It’s an inert, colorless liquid with an interesting chemical structure featuring a silicon atom attached to both methyl groups and three methoxy groups, Methyltrimethoxysilane’s molecular weight is 136.22 while its density about 0.9g/cm3, boil point of 102degC and flash point of 11degC; it’s easily soluble with organic solvents like methanol, ethanol or acetone, yet water will quickly hydrolyze and release its content rapidly into solution releasing methanol back out as soon as it contacts water surfaces.

One of the main uses for methyltrimethoxysilane is as a crosslinker in room temperature vulcanized silicone rubber, where it reacts chemically with other components to form an interwoven network that gives rubber superior mechanical and thermal resistance properties. Additionally, this chemical solution is often employed for surface treatment of glass fibers and external treatment of reinforced plastic laminates. Methyltrimethoxysilane can enhance adhesion between fiber and resin by creating a thin siloxane film on its surface, improving mechanical properties, heat resistance, moisture resistance and moisture absorption of composite materials. Electronic industry manufacturers can also utilize it as a surface modifier on printed circuit boards in order to increase adhesion between circuit board and conductive layer and improve electrical performance and reliability.

Alcoholysis dechlorination and dehydrogenation reactions using methyltrichlorosilane as the raw material typically yield methyltrimethoxysilane; the process requires strict control of reaction conditions to ensure its purity and quality, with special attention paid during storage and transportation due to its hydrolytic and flammable characteristics; appropriate safety precautions must be taken during hydrolysis to avoid harm to both the environment and human health.

Methyltrimethoxysilane’s applications are vast. Beyond those mentioned above, its uses range from serving as raw material for silicone resin production, organosilicon compound manufacturing and coupling agent for silica production to providing weather resistance and chemical stability in high-end fields such as construction, aerospace medicine and health. With ongoing scientific progress Methyltrimethoxysilane will only continue to gain in importance and support related industries further down their respective growth path.

Nature and Specifications:

| Item | Specification |

| Product Name | Methyltrimethoxysilane |

| CAS No. | 1185-55-3 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | Store below +30°C. |

| form | liquid |

| color | colorless |

| Specific Gravity | 0.955 |

| Odor | Mild odor |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Methyltrimethoxysilane has proven itself a valuable crosslinking agent in the rubber industry, significantly increasing mechanical properties of silicone rubber. Hydrolyzed silanol reacts with rubber molecules to form three-dimensional networks which increase tensile strength, elastic recovery and durability of material. Not only is this process suitable for room temperature vulcanization systems; but you can even tailor crosslinking density according to different working environments for an optimized hardness/flexibility outcome.

Methyltrimethoxysilane can also be used to surface treat glass fiber and composite materials, providing another important application of Methyltrimethoxysilane. Through hydrolysis and condensation reactions, this chemical creates a dense siloxane coating on glass fiber surfaces to enhance interfacial bonding between fibers and resin matrix resins and improve the interfacial adhesion between them. Not only does this treatment improve mechanical strength of composite material composites but it also increases water permeability and chemical corrosion resistance making them ideal applications in aerospace applications as well as automotive lightweight applications as other fields such as aerospace lightweight applications and others.

Methyltrimethoxysilane offers great advantages to the coating and sealant industries with its hydrophobic modification and adhesion enhancement properties. Its hydrolysis product can be used as a functional additive, such as for waterproof coatings. Methyltrimethoxysilane’s hydrolysis product also forms a hydrophobic film layer to block water penetration extending service life of waterproof coatings; in plastic processing it improves surface polarity while increasing adhesion performance for ink or adhesive bonds.

Methyltrimethoxysilane has become an indispensable tool in the production of aerogel insulation. By adding hydrophobic modifiers that introduce methyl groups during sol-gel processes, this hydrophobic modifier provides hydrophilic modifications that help to lower surface energy of aerogel and prevent capillary forces from leading to structural collapse. Aerogel boasts ultra-low thermal conductivity and high specific surface area insulation properties making it suitable for building, industrial and clothing insulation applications. Furthermore, methyltrimethoxysilane can enhance heat resistance and dimensional stability of materials such as epoxy resins or polyurethanes by copolymerization or grafting reactions thus expanding their application further in electronics packaging applications and high temperature adhesive applications as well as many other fields.

Methyltrimethoxysilane can also serve the environment by treating wastewater and recovering resources, particularly through hydrolysis by-product methanol distillation for reuse; while pH and temperature controls of its reaction system help minimize emissions; an approach in keeping with green chemical industry development trends.

The core advantage of methyltrimethoxysilane comes from its unique chemical structure design. As an inert substituent, the methyl group not only stabilizes the molecular skeleton, but also gives the final product hydrophobicity and thermal stability. In contrast, the high reactivity of the methoxy group ensures its high efficiency in interfacial reactions. This “stable-active” dual-functional structure enables it to maintain a performance balance in complex applications, such as maintaining the structural integrity of the material in a high-temperature environment, while enhancing interfacial bonding through surface modification.

From a process perspective, the hydrolysis and condensation reactions of methyltrimethoxysilane are highly controllable. By adjusting the pH value (such as using NaOH or ammonia water under alkaline conditions), temperature (20–60°C) and solvent system (water/alcohol mixed medium), the reaction path can be precisely controlled and the formation of by-products can be inhibited. For example, a water/alcohol mixed solvent can slow down the hydrolysis rate and reduce the gelation problem caused by premature condensation, thereby improving the uniformity of the product. This flexibility enables it to adapt to the process requirements of different industrial scenarios, such as fast-curing sealants and coating systems that require long-term stability.

Environmental protection and economy are also significant advantages of methyltrimethoxysilane. The raw materials (methyltrichlorosilane, methanol) used in its preparation are mostly industrial by-products, which reduces production costs; the methanol produced by hydrolysis can be recycled and reused, reducing resource waste. In addition, the application of Methyltrimethoxysilane can reduce the use of harmful additives in traditional materials, such as replacing fluorinated hydrophobic agents in coatings to reduce environmental load.

In terms of performance, the broad spectrum applicability of Methyltrimethoxysilane makes it a key material for cross-innovation in multiple fields. Whether it is enhancing the mechanical properties of rubber, improving the interfacial strength of composite materials, or giving aerogels superhydrophobic properties, Methyltrimethoxysilane exhibits the characteristics of “one dose, multiple effects”. The adjustability of its molecular structure (such as by changing the degree of methyl substitution) further expands the customized application space and meets the demanding requirements for material performance in high-end fields.

Contact Us

Product Package picture:

Related References:

chemicalbook-Methyltrimethoxysilane

Methyltrimethoxysilane Manufacturer

Contact Us

As an experienced Methyltrimethoxysilane manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Methyltrimethoxysilane CAS 1185-55-3 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.