Diethylene Glycol Monobutyl Ether CAS 112-34-5

Factory wholesale Diethylene Glycol Monobutyl Ether CAS 112-34-5

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Diethylene Glycol Monobutyl Ether

CAS: 112-34-5

MOQ: 1KG

Directory Guidance on Diethylene Glycol Monobutyl Ether

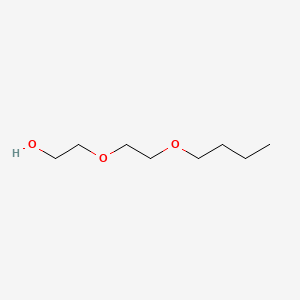

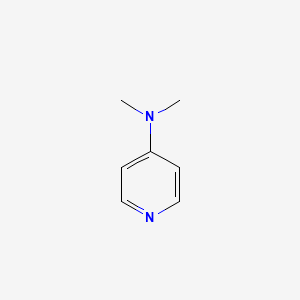

Chemical Structure

Basic Info:

| Melting point | -68 °C (lit.) -68 °C (lit.) |

| Boiling point | 231 °C (lit.) |

| density | 0.967 g/mL at 25 °C (lit.) |

| vapor density | 5.6 (vs air) |

| vapor pressure | 30 mm Hg ( 130 °C) |

Product Introduction:

Diethylene Glycol Monobutyl Ether (DEGBE for short) is an important organic compound with the formula C8H18O3. This colorless liquid with slight aromatic aroma contains two ethylene glycol groups in its molecular structure for improved solubility and low volatility – making DEGBE an excellent organic solvent solution.

Physical Properties for Diethylene Glycol Monobutyl Ether include its melting point at -68, its boiling point at 231, density being approximately 0.967 g/mL (25) and refractive index being 1.432 (20). Diethylene Glycol Monobutyl Ether can be miscible with water in any proportion and also dissolve various organic materials such as oils, dyes, natural resins and nitrocellulose; its flash point being closed 78/open 93; thus making storage and use relatively safe; care should be taken to avoid contact with strong oxidants or strong oxidants such as strong oxidants.

Diethylene Glycol Monobutyl Ether’s primary use is as a solvent in coatings, inks, resins and other industries, including detergents. It can be effectively utilized for dissolving various organic compounds while improving adhesion and stability of coatings as well as decreasing volatilization rate thereby improving quality and gloss of coatings. Furthermore, Diethylene Glycol Monobutyl Ether can also be utilized as plasticizers, hydraulic brake fluid diluents or even as intermediates for organic synthesis.Diethylene Glycol Monobutyl Ether can also be used as plasticizers/ diluents/ organic synthesis as an intermediate for organic synthesis while in detergent production it also has good solubility/permeability properties making this material.

Diethylene Glycol Monobutyl Ether’s low toxicity level (the oral LD50 for rats is 6560 mg/kg) means it has minimal effects on both human and environmental health when used normally, but care must still be taken to avoid breathing in its vapor or skin contact for extended periods. Therefore, its storage should take place in an ambient warehouse that has adequate ventilation while being free from fire and heat sources and equipped with appropriate firefighting equipment.

Nature and Specifications:

| Item | Specification |

| Product Name | Diethylene Glycol Monobutyl Ether |

| CAS No. | 112-34-5 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| refractive index | n20/D 1.432 |

| Fp | 212 °F |

| storage temp. | Store below +30°C. |

| solubility | soluble in Chloroform |

| form | Liquid |

| pka | 14.37±0.10(Predicted) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

In the coating industry, the core value of Diethylene Glycol Monobutyl Ether is its excellent leveling and wetting properties. Adding 0.5-1.5% DGBE can significantly reduce the surface tension of the acrylic resin system, eliminate the orange peel defect on the coating surface, and promote the directional arrangement of metal pigments. Test data shows that the distinctness of image (DOI) index of automotive metallic glitter paint using Diethylene Glycol Monobutyl Ether can be increased to above 0.8, and the solvent release gradient during the drying process better matches the film-forming dynamics of water-based coatings, avoiding the pinhole or shrinkage problem that traditional solvents are prone to produce.

In the field of printing inks, Diethylene Glycol Monobutyl Ether uses its high solubility in nitrocellulose (45g/100ml, 25℃) and controllable volatilization rate. In the formulation of gravure inks, a 20-35% DGBE ratio can ensure that the ink dries at a speed of 50-80 m/min in a 60℃ drying tunnel, and avoids the flying ink phenomenon during high-speed printing. For UV curing inks, its compatibility with free radical photoinitiators (such as TPO) is better than that of propylene glycol methyl ether, the curing efficiency is increased by 18-22%, and the internal stress of the cured film layer is lower. The adhesion test (ASTM D3359) can reach 4B grade.

Industrial cleaning agent is another important application scenario of Diethylene Glycol Monobutyl Ether. In precision electronic cleaning, after 5-8% DGBE is compounded with citrate, the removal efficiency of rosin flux exceeds 99.99%, and the corrosion rate of metals such as copper and aluminum is less than 0.5 Å/min. In the semiconductor packaging process, DGBE-based cleaning agents have gradually replaced ozone depleting substances

The textile printing and dyeing industry has optimized the high temperature and high pressure dyeing process of polyester by introducing Diethylene Glycol Monobutyl Ether. As a dyeing carrier, it can significantly reduce the dyeing bath ratio (from 1:15 to 1:8), the dye uptake rate is increased to more than 95% (130℃), and the rubbing color fastness of the dyed fabric is increased by 0.5-1 level.

Diethylene Glycol Monobutyl Ether is increasingly used as a co-solvent in agricultural chemical formulations. The solubilization of DGBE on the active ingredients of pesticides can reduce the amount of surfactant used by 15-20%, thereby reducing the foam generation during spraying and improving the efficiency of field application.

The emerging field of lithium battery manufacturing has also begun to explore the technical potential of Diethylene Glycol Monobutyl Ether. As an electrolyte additive (addition amount 0.5-1%), it can regulate the formation process of SEI film and inhibit the growth of lithium dendrites.

Diethylene Glycol Monobutyl Ether stands out from its competitors due to its unique multifunctional solubility properties. With a Hildebrand solubility parameter between ketones and alcohols (19.8 MPa0.5), Diethylene Glycol Monobutyl Ether dissolves high-polarity polymers such as epoxy resins (SP=21.3) while forming homogeneous systems with phthalate plasticizers (17.6); its application in nitrocellulose lacquer application shows its volatilization rate (based on butyl acetate). This slow release property effectively avoids leveling defects caused by too fast drying of coating surface coating surface.

Environment compliance is at the core of its market penetration. Diethylene Glycol Monobutyl Ether’s popularity among cleaners has steadily grown as more formulas use it in place of glycol ether solvents, with LCA studies showing its carbon footprint reduction by 32% while its algae control capacity being >100mg/L; making EHS audits much simpler to pass.

Diethylene Glycol Monobutyl Ether excels at both heat resistance (thermal decomposition temperature 245) and chemical inertness. When applied as powder coating extrusion agent (180-200), there will not be thermal cracking or yellowing; when used for polyurethane curing system use it has good compatibility with organic tin catalysts without isocyanate side reactions thus maintaining mechanical property stability of products produced using Diethylene Glycol Monobutyl Ether.

Economic benefits are significant; Diethylene Glycol Monobutyl Ether offers significant savings over its counterpart Propylene Glycol Phenyl Ether (PnB), with unit costs that are 35-40% lower and flashpoints up to 105. Additionally, storage and transportation requirements can be reduced significantly with its hazardous chemical qualification-free nature, thus cutting supply chain management costs significantly. When used for textile printing and dying processes such as printing/dyeing operations using Diethylene Glycol Monobutyl Ether costs per ton by 200-300 Yuan while cutting wastewater treatment costs by 30%!

Diethylene Glycol Monobutyl Ether’s molecular modifiability provides opportunities for technological innovation. By adding propoxy chain segments to synthesized butoxypropoxy derivatives, their HLB values can be precisely controlled in the range of 4-9; this feature is key for making pesticide microemulsions and nanoemulsions more manageable and safer to apply in pesticide applications.

Contact Us

Product Package picture:

Related References:

chemicalbook-Diethylene Glycol Monobutyl Ether

Diethylene Glycol Monobutyl Ether Manufacturer

Contact Us

As an experienced Diethylene Glycol Monobutyl Ether manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Diethylene Glycol Monobutyl Ether CAS 112-34-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.