Cyclohexyl Methacrylate CAS 101-43-9

Cyclohexyl Methacrylate CAS 101-43-9 With Free Sample

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Cyclohexyl Methacrylate

CAS: 101-43-9

MOQ: 1KG

Directory Guidance on Cyclohexyl Methacrylate

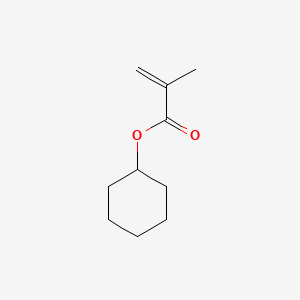

Chemical Structure

Basic Info:

| Boiling point | 68-70 °C4 mm Hg(lit.) |

| density | 0.964 g/mL at 25 °C(lit.) |

| vapor pressure | 18.4Pa at 20℃ |

| refractive index | n20/D 1.458(lit.) |

| Fp | 181 °F |

| storage temp. | Sealed in dry,Room Temperature |

Product Introduction:

Cyclohexyl Methacrylate has an approximate density of 0.965 grams/cm3, refractive index 1.4598 and boiling point of 210degC; its flash point ranges between 90degC (open cup) or 74degC (closed cup). It can be dissolved with various organic solvents like ethanol, ether and chloroform but remains water insoluble; additionally it possesses some degree of hydrophobicity.

There are two primary methods for the production of Cyclohexyl Methacrylate: direct esterification of methacrylic acid with cyclohexanol or transesterification from methyl methacrylate with cyclohexanol; or transesterification from methyl methacrylate with cyclohexanol. When conducting either method, catalysts (such as macroporous sulfonated styrene cation exchange resin) and inhibitors (hydroquinone) may be required to optimize reaction efficiency and prevent polymerization from taking place; optimization also improves purity and yield by controlling reaction temperature, time, catalyst dosage/raw material ratio and raw material ratio during production process.

Cyclohexyl Methacrylate can be found in many fields of use, including coatings, plastics, optical materials and adhesives. Within the coating industry it can be used to prepare hydroxyl acrylic dispersions and acrylic anticorrosive coatings that have high solid content, low viscosity and good stability while being low VOC content; furthermore cured paint films possess excellent salt spray resistance, water resistance and weatherproofness properties. Furthermore it can be used to synthesize prism resins and lenses resins along with colorants or resins used as colorants or adhesives while serving medical filling resin applications in dental filling resin applications – its uses extend far beyond its applications in terms of coatings alone!

Cyclohexyl Methacrylate is a vital chemical raw material in many industrial fields due to its outstanding performance and wide application prospects. As technology continues to advance and market demand increases, so will Cyclohexyl Methacrylate’s synthesis process and application range expand even further.

Nature and Specifications:

| Item | Specification |

| Product Name | Cyclohexyl Methacrylate |

| CAS No. | 101-43-9 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | Liquid |

| color | Clear colorless to slightly yellow |

| Odor | ester-like odor |

| Water Solubility | negligible |

| BRN | 2045235 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Cyclohexyl Methacrylate (CHMA) is an organic chemical raw material with multiple industrial uses, particularly in coatings production. CHMA plays an instrumental role in this field by synthesizing high-performance acrylic resins and anti-corrosion coatings characterized by high solid content, low viscosity, good stability and low VOC content; their cured paint film exhibits excellent salt spray resistance, water resistance, weatherproofness. Furthermore, CHMA can also be used to produce polyurethane coatings resistant to condensation water; these are widely employed in automotive painting and recoating processes.

Cyclohexyl Methacrylate can be utilized to produce high-performance photovoltaic battery sealants that meet stringent material requirements in electronics manufacturing and construction, offering excellent adhesion, flame retardancy and electrical insulation properties. Furthermore, chemically resistant polyurethane-based adhesives made using Cyclohexyl Methacrylate adhesives have widespread industrial manufacturing and construction uses.

In the field of plastics and resins, Cyclohexyl Methacrylate is an important monomer that can be used to synthesize a variety of polymers and resins. Polymers with specific properties can be prepared by free radical polymerization, solution polymerization or suspension polymerization. These polymers are widely used in plastic products, fiber, leather and papermaking industries, providing important material support for related industries.

Cyclohexyl Methacrylate is also widely used in the electronics and medical fields. In the electronics industry, it can be used for packaging materials of electronic components. These materials have good insulation and heat resistance, which can protect electronic components from the influence of the external environment. In the medical field, it is used as a raw material for dental filling resins. These resins not only have good biocompatibility, but also have excellent mechanical properties, which can meet the strict requirements of dental restoration.

In addition, Cyclohexyl Methacrylate can also be used to prepare nanomaterials. Through the improved microemulsion polymerization method, nano-sized polymer latex particles with high solid content and low emulsifier concentration can be prepared. These nanomaterials have broad application prospects in the fields of material science and nanotechnology. In short, Cyclohexyl Methacrylate plays an important role in many fields with its excellent chemical properties and wide industrial applications. With the continuous advancement of technology, its application range will be further expanded.

Cyclohexyl Methacrylate (CHMA) is a very ideal chemical raw material, and its advantages are mainly reflected in its chemical properties. It has strong chemical resistance, can resist the attack of various chemicals, and can remain stable even in complex chemical environments. In addition, it has good hydrolytic stability – no less than its performance and hydrolysis tendency in humid conditions. This stability allows it to perform well in many industrial applications, especially when long-term stability is required.

Cyclohexyl Methacrylate is also very reactive chemically. The fact that it can undergo addition reactions with many organic and inorganic compounds makes it widely used in chemical synthesis. This reactivity makes it easy to mix with other chemicals and form new compounds with certain properties; many different industries have such needs. The diversity of reactions leads to its high demand in the chemical market.

In terms of physical properties, Cyclohexyl Methacrylate is also excellent. This can increase the hardness and wear resistance of the polymer, making the material more durable. On the other hand, it can also give the material good flexibility and impact resistance, which will make the material less likely to break or be damaged during use. Another benefit that Cyclohexyl Methacrylate brings is that it has a low viscosity. Therefore, it is easier to handle during processing and easier to mix with other ingredients, which improves production efficiency.

Another great benefit of Cyclohexyl Methacrylate is its weather resistance. It can withstand the effects of factors such as UV rays, heat, cold and humidity, and can maintain its quality even in harsh outdoor conditions. This weather resistance makes it excel in applications such as coatings and optical tools, ensuring that the material maintains good quality for a long time and reduces performance degradation caused by external factors.

In addition to its weather resistance, Cyclohexyl Methacrylate also has strong hydrophobic properties. The cyclohexyl group imparts good hydrophobicity, which not only helps to enhance the material’s waterproof properties, but also helps to reduce the material’s moisture absorption rate. In humid conditions, this hydrophobicity keeps the material dry, thereby maintaining performance. This property becomes crucial in various applications that need to be waterproof or moisture-proof, such as in the packaging of electronic components and the manufacture of optical lenses.

Cyclohexyl Methacrylate has many environmental advantages. It is a low-volatility, low-odor compound that can reduce VOC emissions. This property makes it an environmentally friendly compound, thereby reducing the impact on the environment and meeting the environmental protection requirements of modern society. With future development and increasingly stringent regulations, Cyclohexyl Methacrylate will occupy a favorable environmental position.

Contact Us

Product Package picture:

Related References:

chemicalbook-Cyclohexyl Methacrylate

Cyclohexyl Methacrylate Manufacturer

Contact Us

As an experienced Cyclohexyl Methacrylate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Cyclohexyl Methacrylate CAS 101-43-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.