Cellulose Acetate Butyrate CAS 9004-36-8

Cellulose Acetate Butyrate CAS 9004-36-8 With Quality Wholesale

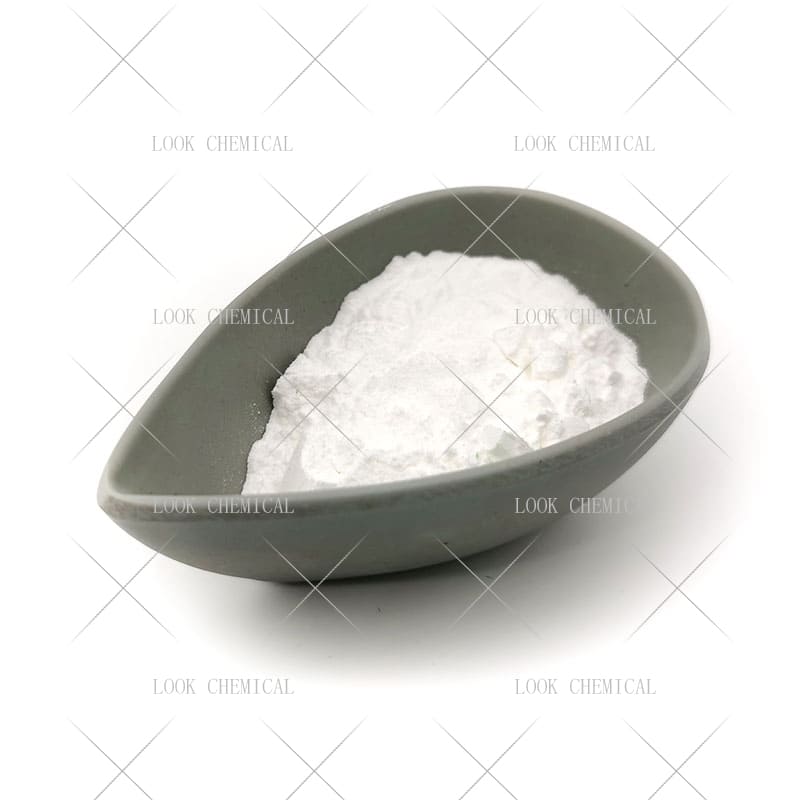

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Cellulose Acetate Butyrate

CAS:9004-36-8

MOQ: 1KG

Directory Guidance on Cellulose Acetate Butyrate

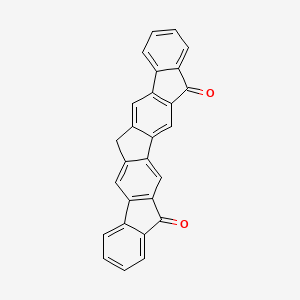

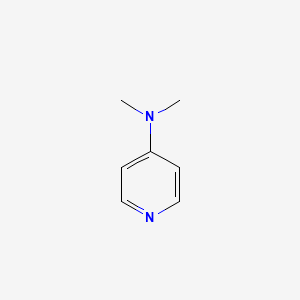

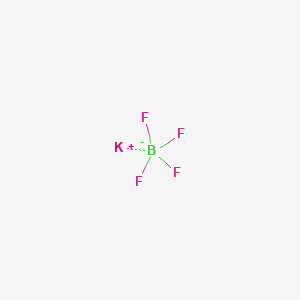

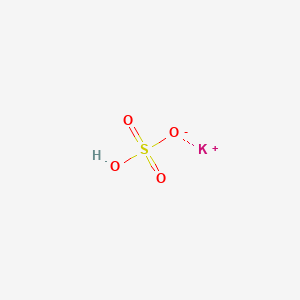

Chemical Structure

Basic Info:

| Melting point | 127-240 °C |

| density | 1.25 g/mL at 25 °C(lit.) |

| refractive index | n20/D 1.475(lit.) |

| storage temp. | 2-8°C |

Product Introduction:

Cellulose Acetate Butyrate (CAB) is an important mixed ester with distinctive physical and chemical properties. This white powder or granular crystalline powder is virtually insoluble in water but dissolves readily in organic solvents such as acetone, formic acid and mixtures of methanol and dichloromethane in equal volumes. Its melting point range spans from 127-240 degrees Fahrenheit while its refractive index stands at 1.475.

Properties of Cellulose Acetate Butyrate are closely tied to its content of hydroxyl, acetyl and butyryl groups. When more acetyl groups were added, melting point and tensile strength increased while compatibility with plasticizers and film flexibility increased with decreasing amounts. An increase in hydroxyl content aids solubility in polar solvents while more butyryl content reduces density while widening dissolution range; it also features excellent moisture resistance, ultraviolet light resistance, cold resistance properties along with flexibility transparency transparency properties as well as electrical insulation properties.

Cellulose Acetate Butyrate is produced through homogeneous esterification of cellulose, acetic acid and butyric acid catalyzed by sulfuric acid. Two production technology routes exist – homogeneous method using organic acid as solvent and heterogeneous method using sulfuric acid – though, in practice, only homogeneous method is currently utilized; extrusion is generally preferred. Due to its excellent processing properties it can also be formed via extrusion, pressure injection, rotation, blow molding or vacuum molding processes as well as boiling spraying techniques.

Cellulose Acetate Butyrate (CAB) is widely utilized due to its exceptional properties. It can be used in plastic sheet base and film manufacturing with excellent transparency and weather resistance properties; can produce oil field natural gas transmission pipeline, tool handles, glass lights for automobiles and aircraft as well as underground telephone lines and cable tubes; is used as raw material in strippable coatings as well as high grade paints weather-resistant high grade paints as well as man made fibers; additionally in the coating industry it plays a significant role improving flexibility, transparency and weather resistance characteristics in coatings production processes.

Cellulose Acetate Butyrate should be stored and transported in an environment free from heat sources and direct sunlight, and protected during transportation from sun or rain exposure. While considered non-toxic, precaution must still be taken when inhaling dust or direct contact with skin and eyes during handling or use.

Nature and Specifications:

| Item | Specification |

| Product Name | Cellulose Acetate Butyrate |

| CAS No. | 9004-36-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | Granular Crystalline Powder |

| color | White |

| Odor | Odorless |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Cellulose Acetate Butyrate (CAB) is an ester material composed of cellulose that has unique physical and chemical properties that make it widely utilized across a wide array of fields.

1. Coating Industry

Cellulose Acetate Butyrate is widely utilized in the coating industry as protective and decorative coatings. Transparent metal varnish can be used to protect aluminum, copper and silver surfaces on buildings from oxidation and corrosion while maintaining their luster. It can also be used as a varnish on plastic products to improve their surface luster and delay aging, and as wood coatings for furniture, floors and other surfaces to extend service life and make them more beautiful. In paper impregnation applications it serves to waterproof strengthen and protect paper products as well as fabric waterproofing applications as well as heat sealing adhesives and glass coatings.

2. Plastics Industry

Cellulose Acetate Butyrate can be utilized in plastics manufacturing processes in many different ways. Depending on its content of butyryl, Cellulose Acetate Butyrate can be formed into moldable items such as telephone bases, car steering wheels, tool handles, toys and pen holders. Furthermore, thin products using Cellulose Acetate Butyrate include water stations, oil fields, natural gas transmission pipelines as well as film bases, aerial film bases, food protective films and oil-resistant product protective films – as well as using thin films used medical fields like skin wound protective films.

3. Ink and Printing

Cellulose Acetate Butyrate is widely used as additives, modified resins or main film forming substances in inks to enhance leveling, reduce pitting and shorten drying times while simultaneously decreasing pressure adhesion and pressure adhesion pressure adhesion pressure adhesion adhesion levels, shorten drying times and provide stable carrier for metal pigments as well as great UV stability and anti-yellowing properties to meet demanding printing environments. Furthermore it has industrial applications including printed circuit board labels serial number nameplate labels and carton pallet pallet labels among many others.

Cellulose Acetate Butyrate finds numerous applications in leather and textile production. It can serve as a leather brightener to give leather its desired high gloss sheen while simultaneously softening and comforting the touch of wearers, and in textile applications can coat and impregnate fabrics like aircraft cloth, car/motorcycle outer cover cloth, sunshade fabric or shower curtains; additionally electrical belts Marine ropes and fire belts may all use CAB impregnation processes as an important method.

5. Other Areas

Cellulose Acetate Butyrate can also be used in other industries to create peeling coatings, insulating paints, weather resistant high grade paints as well as weather proof high grade paints. Medical applications of Cellulose Acetate Butyrate include carrier materials for sustained-release drug systems due to its biocompatibility and degradability properties; alternatively it may be manufactured into artificial fibers for textile industry use.

1. Remarkable physical characteristics

Cellulose Acetate Butyrate stands up well to both cold and weather exposure, remaining physically unchanged throughout a wide temperature range and maintaining its physical properties consistently over time. This property makes it suitable for outdoor and extreme environment applications like automotive paint, plastic film and tool handles.

Flexibility and transparency: Cellulose Acetate Butyrate boasts superior flexibility and transparency properties that meet the requirements of multiple applications. It excels in applications like coatings, plastic sheet bases and films while its flexibility reduces chances of breakage during processing or use.

Cellulose Acetate Butyrate boasts outstanding film forming properties, producing transparent, uniform films with flexible structures that are uniform across their surface area and uniform in color and opacity. These characteristics make Cellulose Acetate Butyrate ideal for use in coatings, plastics and leather coatings, providing both protection and decorative effects while offering good protection.

2. Chemical Stability and Solubility

Chemical Resistance: Cellulose Acetate Butyrate offers excellent chemical resistance, making it a valued asset in both chemical industry and coating applications. It can withstand acids, bases and solvents with ease – which makes this material an integral component for many purposes.

Cellulose Acetate Butyrate’s wide solubility gives it good processability for use in coatings, inks and plastics processing applications. Acetone, methanol and dichloromethane can all dissolve it successfully – giving it plenty of options when it comes to processing capabilities.

3. Processing Performance

Cellulose Acetate Butyrate’s versatile processing methods – extrusion, pressure injection, rotation, blow molding and vacuum molding – enable it to meet the demands for products of various shapes and sizes.

Compatibility with Other Materials: Cellulose Acetate Butyrate is highly compatible with many synthetic resins, high boiling point plasticizers and emulsifiers – making it perfect for composite materials or multi-component systems.

4. Eco-friendliness

Cellulose Acetate Butyrate (CAB) is a type of biopolymer material with certain biodegradability that can gradually break down in natural environments to lessen environmental pollution.

It is generally recognized as being low-toxicity material with minimal effects on both environment and human health during production and usage.

Contact Us

Product Package picture:

Related References:

chemicalbook-Cellulose Acetate Butyrate

Cellulose Acetate Butyrate Manufacturer

Contact Us

As an experienced Cellulose Acetate Butyrate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Cellulose Acetate Butyrate CAS 9004-36-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.