Polyethylene Oxidized CAS 68441-17-8

High Quality Polyethylene Oxidized CAS 68441-17-8

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Polyethylene Oxidized

CAS: 68441-17-8

MOQ: 1KG

Directory Guidance on Polyethylene Oxidized

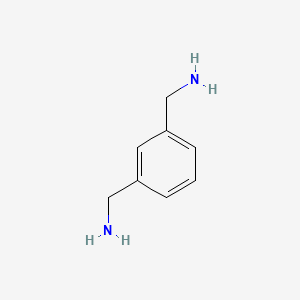

Chemical Structure

Basic Info:

| Melting point | 87-140 °C |

| density | 0.93 g/mL at 25 °C |

| Fp | >254℃ |

| Odor | odorless |

Product Introduction:

Polyethylene Oxidized (PEO) is a crystalline thermoplastic and water-soluble polymer commonly found in white granule form. With a linear, regular helical molecular structure and no distinct smell, PEO has no unique physical state depending on its molecular weight: when greater than 1*10^5, its physical form changes into solid state; when low molecular weight occurs its physical state changes into either liquid or waxy solid (called polyethylene glycol).

Polyethylene Oxidized has excellent water solubility, mixing easily with any proportion of water to form a high-viscosity liquid. Furthermore, its aqueous solution demonstrates high viscosity even at lower concentrations – this makes PEO ideal for thickeners, emulsifiers, lubricants and many other industrial uses. Furthermore, PEO can also dissolve in various organic solvents including alcohols, ketones and chloroform but insoluble in ether and n-hexane; these properties make PEO an invaluable component of chemical, pharmaceutical and other industries alike.

Polyethylene Oxidized has an approximate melting point range of 65-67degC and brittle point at around 50degC, meaning it becomes brittle at low temperatures. PEO has thermoplastic properties which allow it to soften and reshape after heating; viscosity of its aqueous solutions depends on numerous factors, such as molecular weight of polymer molecules in solution concentration, temperature, shear rate, concentration of inorganic salts in solution and shear rate at different temperatures; viscosity decreases at higher temperatures; making PEO an especially valuable material in terms of rheological applications.

Chemical properties of Polyethylene Oxidized show its superior stability: it doesn’t react easily with most chemicals, has high thermal stability and doesn’t hydrolyze. PEO’s versatility also makes it valuable in various applications; flocculation, thickening, slow release, lubrication dispersion retention retention water retention are just a few properties it possess. Furthermore, being nontoxic and nonirritant it is widely used across medicine, cosmetics and food applications.

Nature and Specifications:

| Item | Specification |

| Product Name | Polyethylene Oxidized |

| CAS No. | 68441-17-8 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Chemical Formula | (C2H4O)n |

|---|---|

| Average Molecular Weight | 244.2842 |

| Monoisotopic Molecular Weight | 244.13107375 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Polyethylene Oxidized (PEO) has long been utilized in numerous fields due to its excellent water solubility, chemical stability, non-toxicity and versatility. PEO is often employed as an effective drug sustained-release agent or controlled release system by simply altering molecular weight or concentration to achieve controlled release rate of drug at sustained release rate – making PEO widely utilized for chronic disease treatments as sustained release agent and controlled release system. Furthermore, PEO is often employed in preparation of gels and emulsions which increase solubility or contact time thereby increasing effectiveness thereby further improving efficacy and improving efficacy further.

Polyethylene Oxidized (PEO) is widely used as a thickener, emulsifier and moisturizer in cosmetics and personal care products to enhance their texture and effect. PEO can help thicken creams, conditioners, facial cleansers, moisturizers and eye makeup removers more easily apply and absorb. In addition, PEO can boost moisturizing effects, form thin films by absorbing water, prevent loss and thus provide care for dry or aging skin while simultaneously increasing durability with its certain sunscreening effects that help evenly apply sunscreen evenly on to surface skin surfaces for increased durability.

Polyethylene Oxidized’s application in the food industry mainly manifests itself through thickening, emulsification and modification applications. PEO can significantly enhance taste and consistency in beverages, sauces and ice cream products and prevent food stratification or water separation. Furthermore, PEO is often utilized as a membrane material or preservative in packaging materials as an environmentally friendly packaging solution due to its biodegradability – helping reduce pollution as part of sustainable packaging solutions.

Polyethylene Oxidized is widely utilized across industrial applications including oil field mining, papermaking and textile processing industries as a thickener, dispersant, lubricant or other applications. PEO is particularly useful in oilfield mining to thicken drilling fluids to increase carrying capacity while simultaneously improving drilling efficiency; while papermaking and textile processing utilize it to improve surface quality of paper or softness of textiles. Furthermore, its applications in water treatment applications such as flocculation are significant; PEO can remove impurities such as impurities from suspended matter in water as well as be widely utilized for purifying both drinking and sewage water purification applications.

Polyethylene Oxidized has become an invaluable water treatment agent due to its biodegradability and water solubility, effectively removing oil, suspended solids, and improving overall water quality during treatment. Due to these qualities, PEO has also become a research hotspot in fields like plastic replacement, environmental restoration and ecological preservation; while its degradability greatly reduces pollution in its wake. Therefore, PEO is considered an eco-friendly material.

Polyethylene Oxidized is used extensively in agriculture for creating slow-release fertilizers and as a carrier of pesticides. PEO can slow the release rate, enhance plant absorption efficiency and decrease waste while at the same time improving pesticide usage, reducing environmental pollution, ensuring precise delivery and continuous effects from its pesticide applications.

Polyethylene Oxidized plays an essential role in polymer research and material innovation, as it is widely utilized for high-tech research fields like polymer gels, membrane materials, battery electrolytes and sensors. PEO can provide excellent ionic conductivity with biocompatibility benefits that serve as essential foundation materials in developing new electronic materials.

Polyethylene Oxidized plays a pivotal role in many industries and fields such as medicine, cosmetics, food production, environmental protection, agriculture and scientific research due to its unique properties. Thanks to technological progress, its application prospects will expand further–particularly within green environmental protection applications with high technology developments presenting great growth potential.

1. Outstanding Water Solubility

Polyethylene Oxidized is highly water soluble, making it one of its greatest advantages. When mixed with water in any proportion it forms a high viscosity liquid suitable for making various water-soluble products like drugs, cosmetics and food additives. Furthermore its water solubility has proven especially useful in biomedicine; used as drug carriers or sustained-release systems it allows effective control over drug release rates.

2. Good Biocompatibility and Non-toxicity

Polyethylene Oxidized is widely recognized for its excellent biocompatibility, non-toxicity and lack of irritation to human bodies. Because PEO does not trigger allergic or toxic responses it finds widespread use as an ingredient in medicine and cosmetic products; often being employed as drug carriers, emulsifiers, moisturizers or drug carriers with excellent compatibility to skin or mucous membranes.

3. Chemical Stability

Polyethylene Oxidized is known for its exceptional chemical stability, withstanding most chemical reagents without corrosion or degradation – ideal for chemical engineering and industrial applications.

4. Excellent Thickening and Emulsifying Properties

Polyethylene Oxidized can show high viscosity at low concentrations, making it suitable for use as a thickener, emulsifier, stabilizer and so on. PEO’s thickening property makes it popularly used across food, cosmetics and medicine applications to enhance texture, stability and use effect of products while its oil-water compatibility supports its wide use in products like creams, lubricants and detergents.

5. Biodegradability

Polyethylene Oxidized is an environmental friendly material with excellent biodegradability properties. When in use, PEO will not pollute the environment for long periods and can easily break down in natural settings; this gives PEO a wide array of applications across fields including water treatment, environmental protection and more – particularly replacing traditional plastics in these sectors.

6. Thermoplasticity and Processability

Polyethylene Oxidized has excellent thermoplasticity, softening upon heating to soften and reshape. As its temperature rises, viscosity reduces, making extrusion and injection molding processes simple and flexible enough for industrial uses requiring different forms (solid, gel or liquid).

7. Adjustability of High Molar Weight Polyethylene Oxidized can be altered in its molecular weight by controlling its polymerization conditions and thus changing both physical and chemical properties. A PEO with higher molecular weight typically forms solid or high viscosity liquid states suitable for applications requiring increased viscosity such as drug sustained release or thickening, while lower molecular weight PEO is often employed for products, emulsions or applications which demand fluidity.

8. Wide Applicability

Polyethylene Oxidized has numerous applications across medicine, food, cosmetics, environmental protection, agriculture and industry. In medicine it serves as a drug carrier and sustained release system; cosmetically as thickener/emulsifier. And water treatment/oil field/papermaking industries utilize it as thickener/dispersant. Thus it becomes an indispensable material in various industries.

Contact Us

Product Package picture:

Related References:

chemicalbook-Polyethylene Oxidized

Polyethylene Oxidized Manufacturer

Contact Us

As an experienced Polyethylene Oxidized manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Polyethylene Oxidized CAS 68441-17-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.