Divinylbenzene CAS 1231-74-0

High Quality Divinylbenzene CAS 1231-74-0

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Divinylbenzene

CAS: 1231-74-0

MOQ: 1KG

Directory Guidance on Divinylbenzene

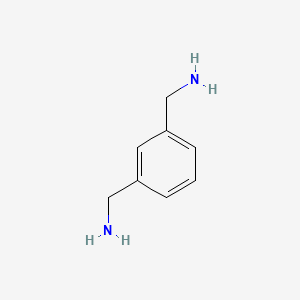

Chemical Structure

Basic Info:

| Melting point | -87.1°C |

| Boiling point | 195 °C(lit.) |

| density | 0.919 g/mL at 20 °C |

| vapor density | 4.5 (vs air) |

| vapor pressure | 0.9 mm Hg ( 30 °C) |

| refractive index | n20/D 1.561(lit.) |

Product Introduction:

Divinylbenzene (DVB) is an organic compound of significant industrial importance. Its molecular structure features two vinyl functional groups that lend it its unique chemical activity and cross-linking ability, giving the chemical its special properties and unique chemical activity. As an unsaturated aromatic hydrocarbon, Divinylbenzene usually exists as a colorless to light yellow liquid at room temperature with an unpleasant pungent odor; its molecular form is C10H10 with the CAS number 1321-74-0; further subdivided into ortho-, meso- and para-isomers with meso- and para-isomers most often being employed industrially.

Divinylbenzene can be synthesized chemically using alkylation reactions on styrene, with Fourier alkylation occurring between benzene and ethylene with acid catalyst, followed by distillation to refine different purities into industrial Divinylbenzene with 55%-85% purity typically being produced. High purity products can be achieved via molecular sieve adsorption or precision fractionation processes.

Divinylbenzene’s physical and chemical properties include its density of about 0.91 g/cm3 at 20 degrees Celsius, its boiling point between 195-210 degrees, and flash point at 74 degrees. As it falls under the Combustible Liquid Management Code during storage and transportation, Divinylbenzene must adhere to stringent safety precautions during handling and storage; insoluble in water yet easily soluble in organic solvents like benzene, toluene and acetone; thus setting its foundation for applications such as polymers.

Reactivity-wise, divinylbenzene contains two vinyl groups which enable it to participate in various reaction mechanisms including free radical polymerization and ionic polymerization processes as well as copolymerization with monomers such as styrene, acrylate or other monomers; especially during copolymerization processes with them such as copolymerization with styrene and other monomers that resulted in excellent cross-linking efficiency. Noteworthy was its susceptibility to autopolymerization upon exposure to air; to prevent autopolymerization during storage conditions while maintaining low temperatures and light resistant conditions during storage industrial storage processes.

Nature and Specifications:

| Item | Specification |

| Product Name | Divinylbenzene |

| CAS No. | 1231-74-0 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Fp | 148 °F |

| storage temp. | Store at +2°C to +8°C. |

| solubility | 5mg/l |

| form | Liquid |

| Specific Gravity | 0.914 |

| color | Colorless to pale yellow |

| explosive limit | 1.1-6.2%(V) |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

As the core material of functional polymer, Divinylbenzene occupies an irreplaceable position in the field of ion exchange resin. When copolymerized with styrene to form a three-dimensional network structure, its crosslinking degree directly determines the mechanical strength and swelling properties of the resin.

In the modification process of special engineering plastics such as polyphenylene sulfide (PPS), the introduction of a small amount of Divinylbenzene can form an intermolecular cross-link point, which can raise the thermal deformation temperature of the material to more than 260℃, and meet the temperature resistance requirement of automotive engine compartment components. In the field of optical materials, copolymers of Divinylbenzene and methyl methacrylate were used to prepare high refractive index lenses. The cross-linking structure of Divinylbenzene and methyl methacrylate suppressed the birefringence caused by internal stress.

The demand for Divinylbenzene in the coatings and adhesives industry is primarily due to its enhancement of curing systems. In UV-curable coatings, Divinylbenzene as the active diluent can not only reduce the viscosity of the system, but also increase the hardness of the coating by more than 2H due to its cross-linked structure. The interpenetrating network structure was constructed by introducing Divinylbenzene derivatives, and the chemical resistance of the cured product was enhanced by 3-5 times.

In the field of analytical chemistry, porous polymer materials derived from Divinylbenzene are widely used as stationary phases in gas chromatography because of their stable pore structure and adjustable surface polarity. The separation efficiency of this type of fillers on C₁-C₂₀ alkanes reached 5000 theoretical plates per metre, showing excellent performance in petroleum fraction analysis. By adjusting the copolymer ratio of Divinylbenzene and polar monomer, the adsorbent matrix of solid phase extraction column can achieve the selective adsorption of different polar compounds. The recovery rate is stable between 90% and 110%. In the molecularly imprinted polymer preparation, the rigid skeleton constructed by Divinylbenzene can accurately fix the holes of the template molecule, so that the detection limit of the sensor can reach ppb level.

In the field of adsorbents, Divinylbenzene cross-linked polymers were developed as new adsorbent materials for environmental remediation and resource recovery. Through the method of thermal regeneration or solvent regeneration, the adsorbent can be recycled many times to reduce the treatment cost. In terms of resource recovery, Divinylbenzene adsorbent can recover precious metal ions such as gold, silver and platinum from industrial wastewater and realize the recycling of resources.

Divinylbenzene’s application in the field of catalyst support is also of great interest. By composite Divinylbenzene with porous materials such as diatomite and activated carbon, catalyst support with high specific surface area and high stability can be prepared. In petroleum refining, this support can support metal catalysts, such as platinum, palladium and nickel, etc., to improve the dispersion and activity of the catalyst. In organic synthesis, Divinylbenzene supported catalysts can be very efficient and exhibit excellent performance in olefin polymerization, hydrogenation and oxidation.

Compared with traditional crosslinkers, the core advantage of Divinylbenzene is firstly reflected in its unique bifocal structure. Each molecule carries two vinyls, which allows it to participate in the formation of two cross-linking points at the same time in radical polymerization, and this property improves the cross-linking efficiency by 40%-60% compared to single vinyl compounds. When the ion exchange resin beads were prepared by suspension polymerization, the standard deviation of the particle size distribution of the beads was controlled within ±5μm, and the loading uniformity of the resin bed was significantly improved. At the same time, the steric hindrance effect caused by bifunctional groups is small, which is conducive to the formation of uniform network structure in the copolymerization process, which is crucial for controlling the pore size distribution of the resin.

The excellent chemical stability is another outstanding advantage of Divinylbenzene. Its aromatic ring structure gives the material excellent thermal oxidation properties, and after 500 hours of aging in 150℃ air environment, the mass loss rate of the cross-linked polymer does not exceed 0.8%. In the strong acid and base medium, the cross-linking network formed by Divinylbenzene can effectively prevent the penetration and swelling of solvent molecules. After soaking in 10% sodium hydroxide solution for half a year, the volume swelling rate of a type of anion exchange resin was still lower than 5%. This stability is also reflected in the radiation resistance, after 50kGy dose of gamma rays irradiation, the material elongation at break retention rate of more than 90%, making it suitable for the special environment in the nuclear industry.

Divinylbenzene was very compatible with most vinyl monomers from the point of view of process adaptability. In solution polymerization system, the difference of repolymerization rate with styrene, butyl acrylate and other monomers is less than 0.2, which ensures the homogeneity of copolymer composition. During the bulk polymerization, the low viscosity of Divinylbenzene (about 3.5mPa ·s at 25℃) was conducive to the timely dissipation of the reaction heat and reduced the exothermal peak temperature by 15-20℃, greatly improving the safety of the polymerization. The low sensitivity to surfactants in the emulsion polymerization system is also a significant advantage, and a stable emulsion with a particle size below 200nm can be obtained by using conventional sodium dodecyl sulfate.

The environmentally friendly nature of Divinylbenzene has made it very popular in the field of green chemistry. Its molecules do not contain halogens, heavy metals and other restricted substances, in line with the requirements of REACH regulations and RoHS directives. In terms of thermal decomposition characteristics, the initial decomposition temperature of Divinylbenzene was up to 310℃, which was much higher than the process temperature range, effectively reducing VOC emissions during the production process. The lifecycle assessment showed that the polymer modified using Divinylbenzene reduced its overall carbon footprint by 18% to 22% compared to the conventional material due to its increased longevity by 30%. In terms of recycling, the cross-linked polymer containing Divinylbenzene can be recovered by pyrolysis with a recovery rate of more than 75%.

The economic advantage is reflected in the cost control of the whole industry chain. As a petrochemical derivative, Divinylbenzene and ethylene are well supplied on the market and their prices fluctuate less than specialty monomers. The maturity of the production process has reduced the cost of large-scale production by about 40% compared with 20 years ago, and the current ton price of industrial grade products is maintained in the range of 12,000 to 15,000 yuan. From the analysis of the use cost, its high cross-linking efficiency makes the addition amount of the unit product only 60% of the traditional cross-linking agent, and the comprehensive cost savings of 15%-20%. Because the transport link has a flash point higher than 60 ° C, it does not need to carry out special control in accordance with flammable dangerous goods, further reducing logistics costs by about 8%.

Contact Us

Product Package picture:

Related References:

chemicalbook-Divinylbenzene

Divinylbenzene Manufacturer

Contact Us

As an experienced Divinylbenzene manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Divinylbenzene CAS 1231-74-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.