Hydroxyethyl Cellulose CAS 9004-62-0

High Quality Hydroxyethyl Cellulose CAS 9004-62-0

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Hydroxyethyl Cellulose

CAS: 9004-62-0

MOQ: 1KG

Directory Guidance on Hydroxyethyl Cellulose

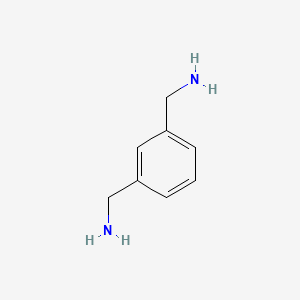

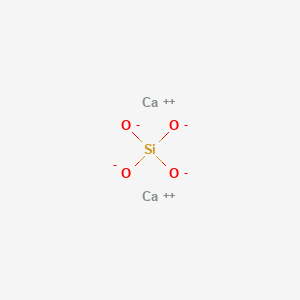

Chemical Structure

Basic Info:

| Melting point | 288-290 °C (dec.) |

| density | 0.75 g/mL at 25 °C(lit.) |

| storage temp. | 2-8°C |

| solubility | H2O: ≤5 wt. % at 20 °C |

| form | powder |

| color | Light brown powder |

Product Introduction:

Hydroxyethyl Cellulose (HEC) is a water-soluble high-molecular compound created through chemical modification of natural cellulose. Its molecular structure follows that of natural cellulose; by adding hydroxyethyl groups it significantly alters its original properties; cellulosic material such as cellulose contains hydroxyl groups on its molecular chain which combine with ethylene oxide via etherification reactions to form HEC structures with different chemical structures derived from them.

Hydroxyethyl Cellulose modification retains some of the crystalline properties of cellulose while also conferring it with superior hydrophilicity and solubility. Based on different degrees of substitution (i.e., number of Hydroxyethyl groups attached to each glucose unit), Hydrophilic Ethyl Cellulose can be divided into three distinct classes depending on viscosity, dissolution rate and solution stability considerations.

Physical Properties – Hydroxyethyl Cellulose can be described as a white or off-white powder with no odor and taste, easily dispersed into water to form an opaque or semi-opaque colloidal solution. Solubility is less affected by temperature, pH value and ionic strength and it swells rapidly both cold and hot water temperatures – a feature distinguishing it from traditional cellulose derivatives like methyl cellulose.

Hydroxyethyl Cellulose forms a three-dimensional network structure in solution through hydrogen bonds and van der Waals forces between molecular chains, producing thickening, suspending and stabilizing effects that demonstrate its versatility in applications ranging from thickening (50 mPa*s) to ultra-high viscosity (200,000 mPa*s) by adapting production process accordingly.

Hydroxyethyl Cellulose production involves three main stages: alkalization, etherification and post-treatment. First, refined cotton laff or wood pulp should be submerged in concentrated alkaline solutions to fully expand its cell walls and expose active hydroxyl groups; afterward an etherification reaction using ethylene oxide is conducted in a high pressure reactor and adjusted by controlling temperature, pressure and time; finally neutralization washing and drying are used to obtain the final product.

This process is highly eco-friendly; the by-products consist primarily of unreacted alkaline solution that can be recycled and reused via circulation system. Furthermore, the degree of substitution directly influences solubility and salt tolerance of Hydroxyethyl Cellulose; products with higher substitution can remain stable in harsh electrolyte environments, while lower substitution products tend to meet greater fluidity requirements in systems.

Hydroxyethyl Cellulose exhibits an intriguing thermal response behavior at microscopic scale. When heated to certain temperatures, its aqueous solution undergoes reversible gelation due to conformational change within its molecular chain. As temperatures increase further, dehydration effects intensify which cause hydrophobic forces between molecular chains, creating physical cross-linked networks between molecules and creating physical cross-linkage networks.

Temperature-sensitivity makes Hydroxyethyl Cellulose ideal for controlled drug release and smart materials applications, as well as being compatible with most anionic and nonionic surfactants; however, certain cationic substances will cause charge neutralization reactions leading to viscosity decrease or precipitation; formula designers must take this characteristic into consideration.

Nature and Specifications:

| Item | Specification |

| Product Name | Hydroxyethyl Cellulose |

| CAS No. | 9004-62-0 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| Odor | Odorless |

| PH | pH(20g/l,25℃) : 5.0~8.0 |

| Water Solubility | almost transparency |

| Merck | 14,4673 |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Hydroxyethyl Cellulose provides self-leveling mortar with an equilibrium between high fluidity and anti-settling property by controlling its rheological properties. Exterior wall putty with superior alkali resistance is crucial in protecting its coating from powdering or peeling off when applied on an alkaline substrate. Hydroxyethyl Cellulose additives in water-based latex paint not only increase can opening effectiveness, but can also prevent pigment sedimentation without diminishing gloss or scrub resistance of the film.

Hydroxyethyl Cellulose finds broad application in the pharmaceutical field. Used as a film-forming material for tablets, it forms an even protective layer on their surface to halt any potential oxidation or degradation of drug components. Hydroxyethyl Cellulose’s water solubility and biocompatibility make it an ideal carrier material, providing control of drug release rate while increasing bioavailability of medication. Hydroxyethyl Cellulose has proven itself in ophthalmic medicines as the key component of artificial tears, mimicking their properties to provide long-acting lubrication that soothes symptoms of dry eye.

The high-end application of hydroxyethyl cellulose in the field of oil extraction is reflected in drilling fluids and fracturing fluids. As a rheological modifier for water-based drilling fluids, its long-chain molecular structure can effectively carry cuttings upward, and at the same time reduce the risk of wellbore collapse through viscoelastic buffering. In the fracturing fluid, the three-dimensional network formed by hydroxyethyl cellulose and crosslinking agent can temporarily increase the viscosity of the liquid, support fracture propagation, and achieve controllable gel breaking through enzymatic hydrolysis or acid hydrolysis. This full-cycle regulation ability of “seam – sand carrying – gel breaking” makes it an indispensable chemical in shale gas extraction. In addition, its lubricating and resistance-reducing effect in the completion fluid can reduce the wear of the drilling tools and prolong the service life of the equipment.

In the food industry, although Hydroxyethyl Cellulose has not been widely approved as a food additive, its application potential in specific fields is gradually emerging. For example, as a fat substitute in low-calorie foods, it improves the texture of the product by simulating the taste of oils and fats; It is used as a film-forming substrate in edible films for the preservation coating of fruits and vegetables. Its safety has passed multiple toxicological evaluations and does not cause sensitization or accumulation risks at the recommended dosage. With the rise of the clean label trend, Hydroxyethyl Cellulose is expected to make a breakthrough in the field of functional food packaging materials due to its natural source attribute and mild processing technology.

The pH adaptability of Hydroxyethyl Cellulose covers a wide range from strong acids to weak bases (pH 2-12), and this broad-spectrum stability stems from its non-ionic molecular structure. In acidic hair dyes, the viscosity retention rate exceeds 90%, while ionic thickeners undergo protonation in this environment, leading to failure; In alkaline cement mortar, its ether bond structure has significantly better hydrolysis resistance than methyl cellulose. This broad applicability reduces the trouble for formulators to frequently change thickeners for different pH systems, especially in products that require cross pH gradient work (such as pH regulating cleaning agents) where the advantages are more prominent.

From a rheological perspective, Hydroxyethyl Cellulose exhibits unique pseudoplastic fluid characteristics – high viscosity at rest to suspend particles, and a sharp decrease in viscosity under shear to facilitate processing or coating. This shear thinning behavior has important value in dynamic processes such as coating rolling and ointment extrusion: it ensures stability during storage without increasing construction energy consumption. More importantly, its thixotropic recovery time can be precisely adjusted through the degree of substitution, which provides customization possibilities for application scenarios that need rapid finalization (such as 3D printing mortar) or slow self-healing (such as gel dressing).

Environmental friendliness is the core competitiveness that distinguishes Hydroxyethyl Cellulose from synthetic polymer materials. Its raw materials come from renewable forest trees or cottonseed fluff, and the carbon footprint during the production process is reduced by more than 60% compared with petroleum-based products. In water environments, it can be gradually degraded by microorganisms into carbon dioxide and water, without causing microplastic pollution. This green attribute perfectly aligns with the global policy orientation of sustainable development. Especially under the impetus of the EU REACH regulation and China’s “dual carbon” strategy, the process of its replacement of traditional non-biodegradable thickeners has significantly accelerated. In addition, the low toxicity feature of the production waste liquid makes it easier to pass the environmental impact assessment approval.

From an economic perspective, Hydroxyethyl Cellulose shows a high cost-effectiveness advantage. Although its unit price is slightly higher than that of starch derivatives, an extremely low addition amount (usually 0.1%-1.0%) can achieve the expected effect, and the unit cost is more competitive. Under extreme conditions such as high-temperature sterilization and frozen storage, its performance attenuation is less than that of gelatin or sodium alginate, reducing the hidden costs caused by product rework rate. For drugs or cosmetics that require export certification, Hydroxyethyl Cellulose meets the global mainstream pharmacopoeia standards such as USP, EP, and JP, significantly reducing the compliance costs of cross-border registration.

Contact Us

Product Package picture:

Related References:

chemicalbook-Hydroxyethyl Cellulose

Hydroxyethyl Cellulose Manufacturer

Contact Us

As an experienced Hydroxyethyl Cellulose manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Hydroxyethyl Cellulose CAS 9004-62-0 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.