Chlorinated Paraffins CAS 63449-39-8

Chlorinated Paraffins CAS 63449-39-8 With Good Service

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Chlorinated Paraffins

CAS: 63449-39-8

MOQ: 1KG

Directory Guidance on Chlorinated Paraffins

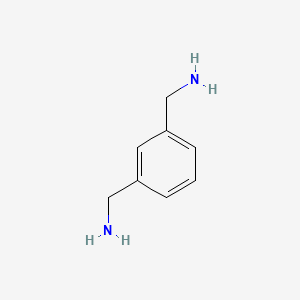

Chemical Structure

Basic Info:

| Melting point | 95-110 |

| Boiling point | 413-508℃ |

| density | 1.387 g/mL at 20 °C(lit.) |

| refractive index | n20/D 1.525 |

| Fp | 392 |

Product Introduction:

Chlorinated Paraffins are organic compounds derived from the chlorination of paraffin. It is soluble in a variety of organic solvents, such as aliphatic hydrocarbons, aromatic hydrocarbons and their chlorides, but insoluble in water, ethanol, ethylene glycol and glycerol.

The physical properties of chlorinated paraffins include high density and low volatility, and usually have good thermal stability and oxidation resistance, which makes it perform well under high temperature conditions. Due to its good corrosion resistance and high electrical insulation properties, it is often used as a plasticizer, flame retardant and stabilizer for plastics and rubbers, especially in wires and cables, building materials and electronic products.

In industrial applications, chlorinated paraffins are of various types and specifications, and can be divided into different grades according to the chlorine content. Chlorinated paraffins with a chlorine content of 40%-52% are light yellow viscous liquids; 54%-60% are viscous yellow semi-solids; 70% are brittle resinous solids. Generally, the most common is a golden or amber viscous liquid with low volatility and non-flammability.

Chlorinated paraffins with higher chlorine content are often used in applications requiring high temperature and high durability, while those with lower chlorine content are more commonly used in the processing of plastics and rubber. With the development of technology, its production and use are gradually improving towards a more environmentally friendly and low-toxic direction.

Nature and Specifications:

| Item | Specification |

| Product Name | Chlorinated Paraffins |

| CAS No. | 63449-39-8 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| refractive index | n20/D 1.525 |

| Fp | 392 |

| solubility | tetrahydrofuran: 0.1 g/mL, clear |

| form | liquid |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

1. Plastic Industry

One of the most common applications of Chlorinated Paraffins is in the plastic and rubber industries, where it is mainly used as a plasticizer, stabilizer and flame retardant. In plastic products, it can improve the softness and toughness of the material and improve processing performance, especially in plastics such as polyvinyl chloride (PVC). It can enhance the weather resistance, heat resistance and chemical corrosion resistance of PVC, and is widely used in the production of daily necessities such as flooring materials, cable sheaths, curtains, etc.

2. Rubber Industry

In the rubber industry, Chlorinated Paraffins are often used to plasticize rubber and improve its processing and physical and mechanical properties. It can increase the heat resistance and aging resistance of rubber, and is often used in the manufacture of rubber products such as automobile tires, seals, conveyor belts and gaskets.

3. Flame Retardant Application

As an excellent flame retardant, it can greatly improve the fire resistance and safety of wires and cables. The high temperature resistance and corrosion resistance of Chlorinated Paraffins make it perform well in the production of cable sheaths, which can improve the oxidation resistance of cables, extend their service life, and reduce the risk of fire. At the same time, it can also provide good electrical insulation performance, which helps to improve the safety and stability of wires and cables.

4. Coatings and paint industries

In the coatings and paint industries, Chlorinated Paraffins are usually used as plasticizers, stabilizers, anti-corrosion agents and anti-fungal agents. It can improve the fluidity of the coating, improve the adhesion of the coating, enhance the water resistance, chemical resistance and UV resistance, and make the coating and paint more stable in harsh environments. This makes it widely used in automotive coatings, industrial coatings, anti-rust coatings, etc.

5. Textile treatment

Chlorinated Paraffins are also used in the textile industry, especially in the waterproof, anti-fouling and anti-fungal treatment of fabrics. As a waterproofing agent, plasticizer or anti-fungal agent, it can increase the durability, moisture resistance and softness of the fabric, and improve the service life of the textile. At the same time, it can also be used to produce special textiles with high temperature resistance, which is commonly used in the production of work clothes, tents, canvas and other products.

6. Metalworking

In the metalworking industry, chlorinated paraffins are often used as metal cutting fluids or lubricants, which can effectively reduce friction and wear during cutting and improve the efficiency and precision of metalworking. It has a good protective effect on the metal surface, can reduce metal oxidation and corrosion, and reduce the heat generated during processing.

7. Environmental protection and fuel

Although chlorinated paraffins may cause certain pollution problems in the environment as chlorinated hydrocarbon compounds, it also has some environmental protection applications. For example, in some chlorinated paraffins with low chlorine content, after treatment, it can be used as an alternative oil for fuel and lubricants, especially for high temperature and high load equipment. Its lubrication performance and thermal stability can improve the operating efficiency of equipment and reduce wear and consumption.

1. Low Volatility

Chlorinated Paraffins have low volatility, meaning their volatilization loss during use at higher temperatures is reduced and thus enhances product stability and safety.

2. High Temperature Resistance and Chemical Resistivity

Chlorinated Paraffins have excellent heat stability under high temperature environments and have excellent chemical resistance properties, making them suitable for manufacturing wires and cables, plastics, rubber products while keeping their physical and chemical properties intact for extended use in high-temperature environments. They are especially well suited to work for longer in these high-temperature environments than their competitors – making it especially suited for use as the building block of various thermoset materials such as paint.

3. Outstanding flame retardant performance

Chlorinated paraffins are effective flame retardants that can dramatically enhance the flameproof properties of plastics, rubber and other materials. By creating a protective barrier around them that inhibits flame spread while delaying combustion processes, chlorinated paraffins help lower fire risks significantly and protect these materials against fire damage.

4. Superior Electrical Insulation

Chlorinated Paraffins have excellent electrical insulation properties, making them widely used in wires and cables, electronic components, and other areas to effectively prevent current leakage while increasing safety and reliability of equipment.

5. Low Cost

Chlorinated Paraffins are relatively cost-effective to produce and can reduce or replace various chemical additives for efficient cost performance in large-scale industrial applications, significantly decreasing production costs while improving product competitiveness. This makes them an attractive industrial raw material option with excellent cost performance that could significantly cut manufacturing costs while increasing competitiveness of your product or service offering.

6. Excellent Processability

Chlorinated Paraffins exhibit excellent fluidity and stability during processing, making it simple to blend them with other raw materials without increasing complexity in production processes. Plastics, rubber and coating applications benefit greatly from using chlorinated Paraffins; production efficiency increases while energy usage decreases significantly – while physical properties of final products improve.

Contact Us

Product Package picture:

Related References:

chemicalbook-Chlorinated Paraffins

Chlorinated Paraffins Manufacturer

Contact Us

As an experienced Chlorinated Paraffins manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Chlorinated Paraffins CAS 63449-39-8 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.