Trimethylolpropane CAS 77-99-6

Free Sample Trimethylolpropane CAS 77-99-6

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Trimethylolpropane

CAS:77-99-6

MOQ: 1KG

Directory Guidance on Trimethylolpropane

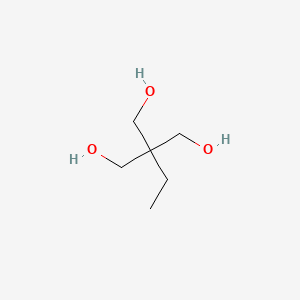

Chemical Structure

Basic Info:

| Melting point | 56-58 °C(lit.) |

| Boiling point | 159-161 °C2 mm Hg(lit.) |

| density | 1.176 |

| vapor density | 4.8 (vs air) |

| vapor pressure | <1 mm Hg ( 20 °C) |

| refractive index | 1.4850 (estimate) |

| Fp | 172 °C |

Product Introduction:

Trimethylolpropane (TMP for short) is an important organic chemical intermediate and fine chemical product, widely used in coatings, resins, plastics, fibers and other fields.

From a physical point of view, Trimethylolpropane is usually presented as a white flake crystal with a melting point of 58.8 ° C, a boiling point of 295 ° C, and a density of 1.0889g/cm³.

The industrial production of Trimethylolpropane is mainly based on the condensation reaction of n-butyraldehyde and formaldehyde under alkaline conditions. By controlling the reaction conditions (such as temperature, pressure and type of catalyst), the purity of the product can be effectively improved and the side reaction can be reduced. After concentration, desalting, ion exchange resin decolorization and film evaporation, high purity product was obtained. Special attention should be paid to dust control and explosion-proof measures in the production process, because TMP dust may form explosive mixtures when mixed with air, and its combustion products include carbon monoxide and carbon dioxide, requiring professional fire fighting equipment. During storage and transportation, TMP should be stored in a cool and ventilated place away from light and isolated from oxidizing agents and acids to prevent moisture absorption or decomposition reactions.

From the perspective of market development, the growth of demand for Trimethylolpropane is mainly due to the expansion of its application in the high-end field. In the domestic market, 85% of TMP is used for the synthesis of alkyd resins, especially high value-added products such as automotive coatings, while the rest is concentrated in the development of plasticizers, surfactants and aerospace lubricants. In recent years, with the tightening of environmental laws and regulations, TMP’s alternative advantages as a bio-based raw material have become prominent, and the number of new construction and expansion projects of its production plants has continued to increase, further promoting the technological upgrading and capacity improvement of the industry.

Nature and Specifications:

| Item | Specification |

| Product Name | Trimethylolpropane |

| CAS No. | 77-99-6 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| storage temp. | Store below +30°C. |

| solubility | H2O: 0.1 g/mL, clear |

| pka | 14.01±0.10(Predicted) |

| form | Flakes |

| color | White |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Trimethyllactone has an exceptional versatility as a multifunctional chemical intermediate in industrial settings. In resin production, Trimethyllactone is widely utilized as a chain extender in alkyd resins, polyester resins and polyurethane applications. TMP introduces cross-linking structures through esterification reactions during the production of alkyd resins, improving their hydrolysis resistance, thermal stability and mechanical strength – qualities ideal for fast drying topcoats with weather resistance properties. Trimethylolpropane can be an extremely versatile additive for polyurethane materials. Not only can it serve as a soft segment modifier to improve elastomers’ anti-abrasion and aging resistance, it can also react with propylene oxide to form polyether polyols – becoming one of the key raw materials of soft foam plastics.

Once again, let’s talk about that thing we love so much: AKA……… the art of living. Ester compounds created through the reaction of Trimethylolpropane with fatty acids have high flash points, low volatility and great high temperature stability; as such they’re widely used in aviation engine oil formulation, automotive lubricants and precision mechanical lubricants. This type of synthetic oil is capable of maintaining its lubricating performance even under intense working conditions above 200, surpassing traditional mineral oils and synthetic ester products in terms of comprehensive performance. Surfactants made of Trimethylolpropane also play an integral part in textile printing and dyeing, cosmetics, and food industries. Example of esterification products used as moisturizers combining safety and efficacy

Trimethylolpropane finds widespread application within the coatings industry. Crosslinking agents, when used as crosslinking agents, can significantly enhance adhesion, chemical corrosion resistance and UV protection of coatings, making them especially suitable for ship paints, industrial anti-corrosion coatings and packaging materials for electronic components. Trimethylolpropane can also serve as a heat stabilizer during polyvinyl chloride (PVC) manufacturing processes, effectively inhibiting degradation and discoloration at elevated temperatures while prolonging service life for products made with it. TMP is used in numerous fields of special application, including propellant coating materials, flame retardant polyurethanes and medical polymers. TMP’s derivatives – such as Trimethylolpropane triacrylate or TMPTA) – serve as essential raw materials for radiation curing technology used to produce wear-resistant UV coatings and inks.

Trimethylolpropane has shown immense promise as an environmentally-friendly plasticizer alternative, due to its reduced toxicity and biodegradability. Phthalate plasticizers were once the standard, but TMP esters have quickly become the go-to option due to their biodegradability and excellent compatibility with PVC, while maintaining excellent electrical insulation properties under humid environments – making it the go-to plastic for cable sheaths and medical devices alike.

From the production side, the synthesis process of Trimethylolpropane is highly mature. By optimizing the reaction conditions (such as pH value, feed ratio and post-treatment process), modern industrial production can stabilize the hydroxyl content above 37.5%, impurities such as formic acid residue control within 0.001%, and crystallization point up to 59℃ (excellent product index). The strict quality control system ensures consistency between batches and meets the demanding requirements for raw material purity in the high-end field. In addition, the application of modular production equipment allows flexible adjustment of production capacity, which can quickly respond to changes in market demand.

The environmental attribute is another core competitive advantage of Trimethyllopropane. As bio based chemicals, their raw materials formaldehyde and butyraldehyde can be prepared through renewable resources, which is in line with the development trend of green chemistry. Compared with petroleum based plasticizers, Trimethyllopropane esters have significantly reduced ecological toxicity, and the wastewater and waste gas generated during production are easier to treat. For example, although its dust requires explosion-proof management, the combustion products are only CO2 and H2O, with no toxic gas release, reducing environmental pollution risks from the source.

At the application performance level, the versatility of Trimethylolpropane allows it to replace many traditional chemicals. Taking plasticizer as an example, its ester products not only have better migration resistance than phthalates, but also can maintain flexibility in a wide temperature range, which is suitable for sensitive scenes such as automotive interior and food packaging. In the field of lubricants, the oxidation stability of Trimethylolpropane ester is far more than that of mineral oil, which can extend the maintenance cycle of equipment and reduce energy consumption. This “one-dose multi-energy” feature reduces formula complexity and helps downstream enterprises reduce comprehensive costs.

Contact Us

Product Package picture:

Related References:

chemicalbook-Trimethylolpropane

Trimethylolpropane Manufacturer

Contact Us

As an experienced Trimethylolpropane manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Trimethylolpropane CAS 77-99-6 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.