Zinc Carbonate CAS 3486-35-9

Zinc Carbonate CAS 3486-35-9 with Best Price

- Appearance:Powder

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Zinc Carbonate

CAS: 3486-35-9

MOQ: 1KG

Directory Guidance on Zinc Carbonate

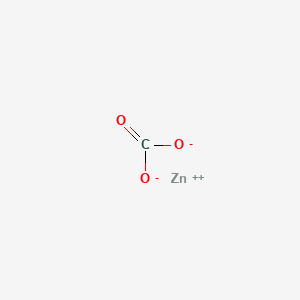

Chemical Structure

Basic Info:

| Melting point | decomposes [KIR84] |

| density | 4,398 g/cm3 |

| solubility | soluble in dilute acid solutions, alkaline solutions |

| form | Solid |

| color | White |

Product Introduction:

Zinc Carbonate (ZnCO₃) is a white inorganic compound that is commonly found in mineral form as a fine white powder or as a precipitate in an aqueous environment. It has a low solubility and is usually insoluble in water, but can be dissolved in acidic solutions to form zinc salts.

Zinc Carbonate decomposes at high temperatures, releasing carbon dioxide gas to form zinc oxide (ZnO). This property makes it chemically active when treated at high temperatures or reacting with acids.

The physical properties of Zinc Carbonate indicate that it has a low specific gravity, usually around 4.5 g/cm³. Its crystal structure is hexagonal, showing a typical colorless or white crystal morphology. In addition, it has poor thermal stability and is easily decomposed when heated, so it is often used in applications that require temperature control. Its water resistance and stability make it one of the components of some special coatings and anti-corrosion materials.

In industrial applications, the advantages of Zinc Carbonate are mainly reflected in its role as a zinc source. As a zinc supplement, it is often used in agriculture, cosmetics, and the pharmaceutical industry. It can effectively provide zinc, which is essential for crop growth, skin care and immune support. For agriculture, it is used as a fertilizer additive to help improve the zinc content in the soil, thereby promoting plant growth and increasing crop yields.

In addition, Zinc Carbonate is also used in the rubber industry as a reinforcing agent or anti-aging agent to improve the durability and antioxidant properties of rubber products. It also plays an anti-corrosion role in certain coatings, especially in metal surface coatings, which can effectively prevent metal rust. In short, its versatility and superior physical and chemical properties make it have a wide range of application prospects in multiple industries.

Nature and Specifications:

| Item | Specification |

| Product Name | Zinc Carbonate |

| CAS No. | 3486-35-9 |

| Appearance | Powder |

| Shelf Life | 2 years |

| Packing | As your requirements |

| form | Solid |

| color | White |

| Water Solubility | mol/L solution H2O: 1.64×10?4 (solubility is given at Pco2=0.00032 bar) [KRU93]; soluble dilute acids, alkalies, NH3 solutions [MER06] |

| Solubility Product Constant (Ksp) | pKsp: 9.94 |

| Dielectric constant | 9.3(Ambient) |

| Stability: | Stable. Incompatible with acids. |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

1. Rubber Industry

In the rubber industry, Zinc Carbonate is used as a reinforcing agent, anti-aging agent and filler. It can improve the mechanical strength, wear resistance and oxidation resistance of rubber and extend the service life of rubber products. Therefore, it is often used in the production of rubber products such as tires, seals, hoses, etc., especially in the manufacture of high-durability rubber materials, it can improve its thermal stability and UV resistance.

2. Coatings and Anti-corrosion Fields

As a preservative, Zinc Carbonate is widely used in the coating industry. It is often used as an anti-rust coating component on metal surfaces, which can effectively prevent metals from rusting in humid environments. The coating formed by mixing it with other ingredients has good adhesion and corrosion resistance, and is widely used in ships, bridges, oil pipelines and other metal surfaces that require anti-corrosion protection.

3. Plastic Industry

Zinc Carbonate is widely used in various plastic products as a filler and reinforcing agent to improve the mechanical strength, hardness and wear resistance of plastic products. It can also increase the density and quality of plastic products and improve the thermal stability and anti-aging properties of plastics.

4. Agricultural field

In agriculture, Zinc Carbonate is often used as a fertilizer additive, especially in zinc-deficient soils, where it can effectively improve crop growth. Zinc is one of the trace elements necessary for plant growth and is involved in plant photosynthesis and enzyme synthesis, so it is of great significance to improving crop yield and quality. It can prevent zinc deficiency symptoms in crops, such as yellowing leaves and dry veins, by supplementing zinc.

5. Pharmaceuticals and nutritional supplements

In the pharmaceutical field, Zinc Carbonate is widely used in nutritional supplements, especially for the treatment of zinc deficiency. Zinc, as an essential trace element for the human body, is essential for the immune system, skin health, cell repair, etc. It is usually used as a zinc source in pharmaceuticals to make zinc tablets, zinc oral solutions and other products to help supplement the zinc required by the human body and alleviate health problems caused by zinc deficiency.

6. Cosmetic industry

In the cosmetics field, Zinc Carbonate is used as a skin care ingredient with anti-inflammatory, astringent and anti-inflammatory effects. It is often used as an active ingredient in sunscreens, talcum powders and various skin care products. It can effectively improve skin conditions, especially relieving symptoms such as acne and skin allergies. Its low irritation and good skin compatibility make it a common raw material for skin care products.

7. Other industrial applications

Zinc Carbonate is also used in some other industrial fields. For example, in the ceramic industry, it is used as a glaze to increase the gloss of the ceramic surface. In the electronics industry, it is also used as a piezoelectric material that can generate electrical signals under pressure.

In general, Zinc Carbonate has become an indispensable raw material in many industries due to its good chemical stability, biocompatibility and the role of supplementing zinc.

When using Zinc Carbonate, although it has important applications in many fields, it is also necessary to pay attention to the following aspects to ensure its safety and effectiveness:

1. Storage and transportation

Zinc Carbonate should be stored in a dry, cool place and avoid contact with strong acids or alkaline substances. It is not resistant to high temperatures, and excessive temperatures may cause it to decompose. During transportation, the packaging should be intact to avoid moisture or external environment, especially moisture or contact with acidic substances, so as to avoid chemical reactions.

2. Control of dosage

When using Zinc Carbonate in agriculture, the dosage must be strictly controlled. Excessive use may cause excessive zinc content in the soil, which in turn affects the growth of crops and even causes plant poisoning. It is best to conduct soil testing before use to ensure that the zinc content is suitable for plant growth. For crops, an appropriate amount of zinc is necessary, but excessive use will affect the normal growth of plants and may even have a negative impact on the soil ecosystem.

In terms of pharmaceuticals and nutritional supplements, when Zinc Carbonate is used as a zinc supplement, excessive use may also have negative effects on health, such as gastrointestinal discomfort, diarrhea, dizziness and other symptoms. Therefore, when using it, it should be used according to the advice of professionals or dosage requirements to avoid overdose.

3. Personal protection measures

When using Zinc Carbonate, especially in industrial production, it is recommended to take appropriate personal protection measures. Zinc Carbonate powder may irritate the respiratory system, and long-term inhalation of excessive zinc dust may cause zinc poisoning. Therefore, when operating, especially in dusty environments, dust masks and appropriate protective equipment (such as gloves, glasses, etc.) should be worn to avoid irritation to the skin and eyes.

4. Compatibility with other chemicals

Zinc Carbonate may react with certain chemicals, especially strong acids. It reacts with acids to produce carbon dioxide gas, which may cause bubbles and pressure changes, so avoid mixing it with strong acids (such as sulfuric acid and hydrochloric acid). In industrial applications such as coatings and rubber, it should be ensured that its formula is compatible with other raw materials to avoid adverse reactions or affect the quality of the final product.

Contact Us

Product Package picture:

Related References:

chemicalbook-Zinc Carbonate

Zinc Carbonate Manufacturer

Contact Us

As an experienced Zinc Carbonate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Zinc Carbonate CAS 3486-35-9 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.