Ethyl Oleate CAS 111-62-6

Factory wholesale Ethyl Oleate CAS 111-62-6

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Ethyl Oleate

CAS: 111-62-6

MOQ: 1KG

Directory Guidance on Ethyl Oleate

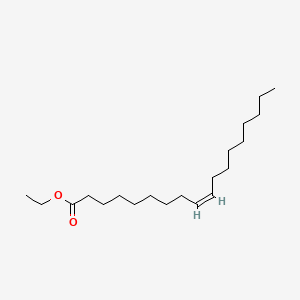

Chemical Structure

Basic Info:

| Melting point | −32 °C(lit.) |

| Boiling point | 216-218 °C15 mm Hg |

| density | 0.87 g/mL at 25 °C(lit.) |

| FEMA | 2450 | ETHYL OLEATE |

| refractive index | n20/D 1.451(lit.) |

| Fp | >230 °F |

| storage temp. | -20°C |

Product Introduction:

Ethyl Oleate (C19H36O2) is an important organic compound with the formula C19H36O2, manufactured through esterification of oleic acid with ethanol. Ethyl Oleate is an unsaturated long-chain fatty acid ester whose molecular structure contains an unstable double bond, making it highly reactive chemically. At room temperature, Ethyl Oleate is a colorless to pale yellow transparent liquid with a slight oily odor. Its boiling point is approximately 216°C, and its density is 0.87g /cm³. It is almost insoluble in water but miscible with most organic solvents. This hydrophobic property enables it to demonstrate unique compatibility in industrial applications. From the perspective of the preparation process, the synthesis of Ethyl Oleate is usually carried out by acid-catalyzed transesterification or direct esterification. By controlling the reaction temperature, type of catalyst and purity of raw materials, a conversion rate of over 95% can be achieved.Furthermore, double bond structures within its molecules can be transformed into saturated esters through hydrogenation reactions further expanding its applications in materials science.

Physical and chemical properties of Ethyl Oleate make it an excellent lubricant; with low viscosity and excellent fluidity properties that make it particularly suitable in this field.At the same time, it has a high flash point (about 110°C), is not easy to volatilize at room temperature, and has excellent storage stability, which provides safety for large-scale industrial use. Through infrared spectroscopy and nuclear magnetic resonance analysis, it can be seen that the characteristic peak of the ester group in its molecule is obvious, which provides a reliable analytical basis for quality control. In a low-temperature environment, Ethyl Oleate can still remain in liquid form. This wide liquid temperature range makes it show special value in applications in cold regions.

From the perspective of molecular structure, Ethyl Oleate has both lipophilic ester groups and long carbon chain structures. This amphiphilic property makes it hold an important position in the field of surfactants. The length of its carbon chain and the position of its double bonds directly affect the interaction forces with other substances. For example, in polymer materials, the flexibility of the carbon chain can effectively improve the processing performance of the material.

In recent years, the introduction of enzyme catalytic technology has significantly enhanced the selectivity of the reaction while reducing energy consumption. Against the backdrop of increasing environmental protection pressure, enterprises generally adopt closed-loop production processes to achieve the recycling of by-products. In terms of raw material selection, the popularity of bio-based ethanol has made the sustainability characteristics of Ethyl Oleate more prominent, which is in line with the global development trend of green chemistry. It is worth noting that the purity indicators of different grades of products directly affect the terminal application effect. Pharmaceutical-grade products require impurity content to be less than 0.1%, which poses extremely high demands on distillation technology.

Nature and Specifications:

| Item | Specification |

| Product Name | Ethyl Oleate |

| CAS No. | 111-62-6 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

| solubility | chloroform: soluble10% |

| form | Oily Liquid |

| color | Clear |

| Odor | at 100.00 %. fatty oily dairy milky waxy tallow |

| Odor Type | fatty |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

Ethyl Oleate is widely used as a base oil component of metalworking fluids. Its molecules can form a directional adsorption film on the friction surface, effectively reducing the wear rate of mechanical parts. Compared with mineral oil, the characteristics of bio-based products make them easier to be decomposed by microorganisms, and are particularly suitable for the lubrication of precision instruments with strict environmental requirements. Under high temperature conditions, the addition of anti-wear additives can significantly enhance its load-bearing capacity. This adjustability makes it occupy an important position in the special lubricant market. In some composite lubrication systems, Ethyl Oleate can also produce a synergistic effect with extreme pressure additives to further expand the application temperature range.

In the coating industry, Ethyl Oleate is mainly used as a reactive diluent.By altering the ratio of Ethyl Oleate added, UV curing systems allow users to precisely control the balance between flexibility and hardness in coatings. Notable aspects of Ethyl Oleate include its unsaturated double bonds serving as sites for free radical polymerization, providing design ideas for environmentally-friendly coatings. Furthermore, its slow hydrolysis properties create microphase separation structures to extend the action time of antifouling agents on ships.

The plastic processing industry regards Ethyl Oleate as an important candidate material for plasticizers. Compared with traditional phthalate plasticizers, it has a lower mobility and can significantly improve the aging properties of plastic products. In PVC products, the addition of Ethyl Oleate can reduce the glass transition temperature of the material by 15-20°C while maintaining a high tensile strength. With the upgrading of food contact material standards, its non-toxic properties enable it to quickly replace traditional plasticizers in the field of food packaging films. In biodegradable plastic systems, Ethyl Oleate can also accelerate the enzymatic hydrolysis process of microorganisms. This unique degradation-promoting effect is attracting the attention of the scientific research community.

Its application in daily chemical products is mainly reflected in the formulation of personal care products. Hair wax products with different styling strengths can be customized through changing the carbon chain length distribution of Ethyl Oleate, thus providing personalized solutions in haircare. It is worth noting that its low freezing point at room temperature allows skin care products containing this ingredient to maintain a good use experience in cold environments.

The pharmaceutical industry’s application of Ethyl Oleate is concentrated in transdermal drug delivery systems. As a drug carrier, it can effectively promote the penetration of lipophilic drugs through the stratum corneum and improve bioavailability. In microencapsulation technology, its interfacial activity helps to form a stable drug sustained-release system. Some nanoformulations of anticancer drugs use Ethyl Oleate as a stabilizer, using its amphiphilic properties to control the particle size distribution of nanoparticles. In the development of transdermal patches, the drug release rate can be precisely controlled by adjusting the ratio of Ethyl Oleate to polymer. This controlled release property makes it a hot material in the research of new drug delivery systems.

The core competitiveness of Ethyl Oleate is first reflected in its environmentally friendly characteristics. As a bio-based material, its production raw materials come from renewable resources, and its carbon footprint throughout the life cycle is more than 40% lower than that of petroleum-based products. The continued tightening of the EU REACH regulations has made this degradable property a key competitive advantage in entering the European market. From the perspective of the supply chain, the sufficient supply of global vegetable oil raw materials ensures the stability of production, especially in the main production areas of palm oil and rapeseed oil, where the raw material cost advantage is more obvious.

In terms of chemical properties, Ethyl Oleate exhibits excellent compatibility. The compatibility index with most polar resins exceeds 0.85, making it irreplaceable in complex systems due to its broad compatibility. During high-temperature processing, its thermal decomposition temperature reaches 280 ° C, which can meet common process requirements such as injection molding and extrusion. In the field of conductive materials, Ethyl Oleate has a moderate dielectric constant and is particularly suitable for the construction of insulation layers in electronic packaging materials. In the design of antioxidant systems, by introducing steric hindrance type antioxidant groups, the oxidation induction period can be extended to over 120 hours, and this modifiable feature greatly enhances the environmental adaptability of the product.

From an economic perspective, Ethyl Oleate has obvious advantages in unit performance cost. Under the same lubrication effect, its usage can be reduced by 30% compared with mineral oil, and long-term use significantly reduces maintenance costs. In the coating system, as a reactive diluent, it can reduce the use of solvents by 30-50% and increase the solid content at the same time. This dual benefit is favored by formulators. The maturity of large-scale continuous production technology has reduced the energy consumption per ton of product by 45% compared with ten years ago, and the cost advantage brought by the scale effect continues to expand. In the transportation and storage links, its non-flammable properties reduce insurance costs. The marine hazardous chemicals level is Class III, which saves more than 20% of the transportation cost compared with Class I products.

In terms of safety performance, Ethyl Oleate’s toxicological data is excellent. The oral toxicity LD50>5000mg/kg is a practical non-toxic level, which is extremely rare in organic solvents. Skin irritation tests show that its sensitization rate is less than 0.5%, which fully meets the safety standards for cosmetic raw materials. In terms of occupational exposure, its vapor pressure is only 0.01 mmHg (25°C), and the concentration in the workplace air is far below the occupational exposure limit. This safety feature enables it to enter strictly regulated fields such as medicine and food, and has a broader market access space than similar products.

The potential for technological innovation constitutes the long-term competitive advantage of Ethyl Oleate. The double bonds in the molecular structure can be used as chemical modification sites to prepare high-value-added derivatives through reactions such as epoxidation and amination. In the synthesis of nanomaterials, it can be used as a template to guide the formation of metal oxide particles with specific morphology. In the field of fuel cells, researchers are exploring its possibility as a hydrogen storage medium, using the reversible hydrogenation characteristics of unsaturated bonds to increase hydrogen storage density. In bioengineering, the specific metabolic pathways of certain strains for Ethyl Oleate provide a molecular recognition basis for the construction of new biosensors. Breakthroughs in these cutting-edge application directions will continue to promote industrial upgrading.

Contact Us

Product Package picture:

Related References:

chemicalbook-Ethyl Oleate

Ethyl Oleate Manufacturer

Contact Us

As an experienced Ethyl Oleate manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Ethyl Oleate CAS 111-62-6 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.