Hydroxyl-Terminated Polybutadiene CAS 69102-90-5

Factory wholesale Hydroxyl-Terminated Polybutadiene CAS 69102-90-5 With Free Sample

- Appearance:Liquid

- Purity:99.8%

- Delivery:30days

- Sample Available:Available

- Payment:L/C,T/T,D/P,Paypal,Money Gram,Western Union

- Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

- Transporta:Ocean, Land,Air, DHL,TNT FedEx

Name: Hydroxyl-Terminated Polybutadiene

CAS: 69102-90-5

MOQ: 1KG

Directory Guidance on Hydroxyl-Terminated Polybutadiene

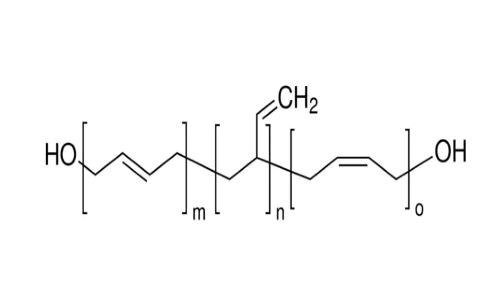

Chemical Structure

Basic Info:

| density | 0.913 g/mL at 25 °C |

| refractive index | n20/D 1.5126 |

| Fp | 113 °C |

Product Introduction:

Hydroxyl-terminated Polybutadiene is a liquid rubber with Hydroxyl (-OH) functional groups at both ends of the hydroxyl-terminated polybutadiene whose main chain is hydroxyl-terminated. The hydroxyl group in its molecular structure gives the material a unique reactive activity, enabling it to form a three-dimensional network structure through chemical reaction with crosslinking agents such as isocyanates and epoxy resins. The molecular weight of Hydroxyl-Terminated Polybutadiene is usually between 2000 and 5000, the viscosity range is adjustable, and the material exhibits excellent flexibility and low temperature resistance due to a high content of 1, 4-cis-structure in the molecular chain (usually exceeding 60%).

Hydroxyl-Terminated Polybutadiene is synthesized by anionic polymerization or radical polymerization. The anionic polymerization route usually uses lithium catalyst, and the molecular weight distribution can be narrowed by precisely controlling the ratio of initiator to monomer. Free radical polymerization is more suitable for industrial mass production, but the molecular weight distribution is relatively wide. Regardless of the process, the introduction of the hydroxyl group must be accomplished by specific end-sealing techniques, such as the addition of ethylene oxide or a terminator containing the hydroxyl group at the end of the polymerization. This process has a decisive effect on the hydroxyl content, molecular weight and distribution of the final product, which in turn affects the processing properties of the material and the mechanical properties of the end product.

In terms of physicochemical properties, Hydroxyl-Terminated Polybutadiene combines the high elasticity of rubber with the curable properties of thermosetting resins. Its glass transition temperature (Tg) is usually below -70 ° C, so it remains flexible at extremely low temperatures. At the same time, the presence of the hydroxyl group makes it compatible with a variety of polar materials, such as polyurethane prepolymers or epoxy resin systems, thus expanding the application boundaries of the material. It is important to note that Hydroxyl-Terminated Polybutadiene has relatively weak oil and ozone resistance, but such defects can be significantly improved by chemical modification (such as the introduction of acrylonitrile units) or physical blending (such as the addition of carbon black).

As a class of functional polymer hydroxyl-terminated Polybutadiene, the properties of hydroxyl-terminated polybutadiene can be precisely regulated by Hydroxyl content, molecular weight distribution, and microstructure. For example, high hydroxyl content can increase the crosslinking density of the material, thereby enhancing the mechanical strength, but may sacrifice some elasticity; Low hydroxyl content is more suitable for scenarios requiring high elongation. This designability makes it an ideal substrate for applications in many fields. At present, Hydroxyl-Terminated Polybutadiene has occupied an important position in the fields of solid rocket propellants, sealing materials, coatings and elastomers, and its technology maturity and market penetration continue to increase.

Nature and Specifications:

| Item | Specification |

| Product Name | Hydroxyl-Terminated Polybutadiene |

| CAS No. | 69102-90-5 |

| Appearance | Liquid |

| Shelf Life | 2 years |

| Packing | As your requirements |

Product service:

- Certificate Of Analysis (COA)

- Material Safety Data Sheet (MSDS)

- Route of synthesis (ROS)

- Method of Aanlysis (MOA)

- Nuclear Magnetic Resonance (NMR)

- Packing pictures and loading video before loading

- Free Sample

- Factory audit

The application of Hydroxyl-Terminated Polybutadiene in the aerospace field is mainly reflected in the preparation of high-performance sealing materials and structural adhesives. Since aerospace equipment needs to operate stably in extreme temperature, high vacuum and high stress environments, the overall performance of materials is highly demanding. After it is combined with epoxy resin, polyurethane and other materials, the sealant formed can maintain good elasticity and sealing performance in a wide temperature range of -100 ° C to 150 ° C, effectively preventing fuel leakage and air intrusion.

In the coatings industry, the introduction of Hydroxyl-Terminated Polybutadiene solves the problem of insufficient adhesion of traditional coatings on flexible substrates such as rubber or plastic. By copolymerizing the product with acrylic monomer, UV curable coating with both flexibility and hardness can be prepared, which is widely used in automotive interior, flexible display screen protective film and other fields. In addition, the weather resistance of Hydroxyl-Terminated Polybutadiene makes it outstanding in Marine anti-corrosion coatings, and the unsaturated double bonds in its molecular chains can form a dense protective layer by oxidative cross-linking, effectively slowing the corrosion process of the metal substrate.

In the field of elastomers, Hydroxyl-Terminated Polybutadiene reacts with polyisocyanates to form a polyurethane elastomer that exhibits better wear resistance and dynamic mechanical properties than conventional rubber. Such materials perform well in heavy-duty scenarios such as mining machinery track plates and high-speed rail shock absorbers. It is worth mentioning that the oil resistance of the Hydroxyl-Terminated polybutadiene-based elastomer can be further improved by introducing fluorination modification to meet the demanding requirements of aerospace hydraulic systems.

In the field of new energy, Hydroxyl-Terminated Polybutadiene is gradually penetrating the market for lithium-ion battery packaging materials. Its low ion mobility and high bond strength can effectively prevent electrolyte leakage and withstand volume changes during battery charging and discharging. With the rise of solid-state battery technology, its potential as a solid electrolyte carrier material has attracted much attention, and its molecular design flexibility provides a new idea for the construction of ionic conductive channels.

The core advantage of hydroxyl-terminated Polybutadiene is due to the high reactivity of Hydroxyl Terminated Polybutadiene. This property not only gives the material excellent thermal stability, but also enables it to achieve a gradient design of performance through formulation adjustment. For example, in scenarios where high toughness is required, more flexible segments can be retained by reducing the cross-linking density; In high-load environments, creep resistance can be improved by increasing crosslinking points.

In terms of processability, the liquid properties of Hydroxyl-Terminated Polybutadiene significantly reduce the complexity of the production process. Its viscosity can be flexibly controlled by molecular weight adjustment or adding diluent, so as to adapt to a variety of molding processes such as pouring, spraying and impregnation. Compared to solid rubber, Hydroxyl-Terminated Polybutadiene can be uniformly mixed with other components without high temperature plasticizing, which not only saves energy but also avoids the negative effects of thermal history on material properties.

Environmental adaptability is another significant advantage of Hydroxyl-Terminated Polybutadiene. The saturated carbon carbon single bond structure in the molecular chain gives the material excellent weather resistance, and it is not easy to break the chain and degrade under the action of environmental factors such as ultraviolet light and ozone. Experimental data showed that the tensile strength retention rate of Hydroxyl-Terminated polybutadiene-based material could remain above 85% after outdoor exposure for 2000 hours. In terms of low temperature performance, its glass transition temperature is much lower than that of ordinary rubber, and it can remain elastic even at -50 ° C, which makes it an ideal choice for special scenarios such as polar scientific research equipment and liquefied natural gas storage tank sealing.

From an economic point of view, butadiene, the feedstock for Hydroxyl-Terminated Polybutadiene, is a bulk petrochemical product with a mature supply chain and controllable costs. After decades of optimization, the synthesis process has achieved a monomer conversion rate of more than 95% and a very low by-product generation. Compared with silicone rubber, fluorine rubber and other special rubber, its raw material cost can be reduced by 30%-50%, which significantly improves the cost performance under the premise of ensuring performance. In addition, the recyclability of Hydroxyl-Terminated Polybutadiene products is also in line with the circular economy trend, and its cross-linked network enables raw material regeneration through chemical depolymerization, reducing the environmental burden.

In terms of technical compatibility, Hydroxyl-Terminated Polybutadiene can form a good interface with a variety of reinforcing fillers such as carbon fiber, glass microbeads and nano-clay. Three-dimensional thermal or conductive networks can be constructed in Hydroxyl-Terminated Polybutadiene substrate by nanocomposite technology, and its applications in emerging fields such as electronic heat dissipation and electromagnetic shielding can be expanded.

Contact Us

Product Package picture:

Related References:

chemicalbook-Hydroxyl-Terminated Polybutadiene

Hydroxyl-Terminated Polybutadiene Manufacturer

Contact Us

As an experienced Hydroxyl-Terminated Polybutadiene manufacturer and supplier, Look Chemical is committed to producing and selling high quality products.

We cooperate and trade with 6000+ factories around the world, and our high-quality products and excellent services make us enjoy a high reputation internationally.

As Hydroxyl-Terminated Polybutadiene CAS 69102-90-5 supplier, Look Chemical provides supply chain solutions to partners and customers in a wide range of industries. We offer competitive pricing and quality products.

If you have a demand for this product, please contact our company’s sales staff, we will provide you with a solution in the shortest time.

Transport proposal

1. For products ≤50kg, we recommend using express delivery, which is usually called DDU service (discounted, convenient).

2. For products ≤500kg, we generally recommend air freight, which is usually called FOB, CFR or CIF service (fast and efficient).

3. For products >500kg, we generally recommend shipping by sea, which is usually called FOB, CFR or CIF service (economical, safe).

4. For high-value products, please choose air or express to ensure the safety of product transportation.

Shandong Lookchemical service:

* Timely reply and 24 hours online, the professional team will provide you with the most favorable prices and high-quality products.

* The sample supports testing and inspection.

* Each batch of products will be tested to ensure that its quality meets user needs.

*Packaging can also be made according to customer requirements.

*Any inquiries will be answered by our relevant personnel within 24 hours.

*We will provide you with commercial invoice, packing list, packing list, COA, health certificate and certificate of origin if you need it. If your market has other special requirements, please let us know.

*We will monitor the logistics information in real time and will share the information with you.

* You can consult us at any time if you have any questions about the product, and we will answer you in time.

*If you have any questions about the product, you can report it to us, we will deal with it in time for you, and the product can be returned.

Contact Us

Frequently Asked Questions(FAQ):

We will make samples before mass production, and after sample approved, we’ll begin mass production. Doing 100% inspection during production, then do random inspection before packing.

Our MOQ is 1kg. But usually we accept less quantity such as 100g on the condition that sample charge is 100% paid.

Yes. We’ll give you product analysis report before shipping.

Different quantity has different discount.

Yes. Welcome to visit.

You can get free samples for some products,you only need to pay the shipping cost or arrange a courier to us and take the samples. You can send us your product specifications and requests,we will manufacture the products according to your requests.